Bottlenecks can be an unexpected and costly burden on your Home & Lifestyle business. The term is used to describe a point of congestion in a production system. It usually happens when workloads in the production supply chain occur too quickly or slowly at certain points and lead to a build up further down the line. Home & Lifestyle manufacturers try to avoid bottlenecks at all costs, for when they do occur, they affect the flow of manufacturing and bring inefficiencies that generally lead to delays and significantly higher production costs.

The chance of bottlenecks occurring tends to increase when new products are launched, as there may be unforeseen flaws in the production process that need to be identified and fine-tuned. Demand spikes are also a common cause as they put additional strain on the production line and some aspects of the manufacturing process may struggle with capacity.

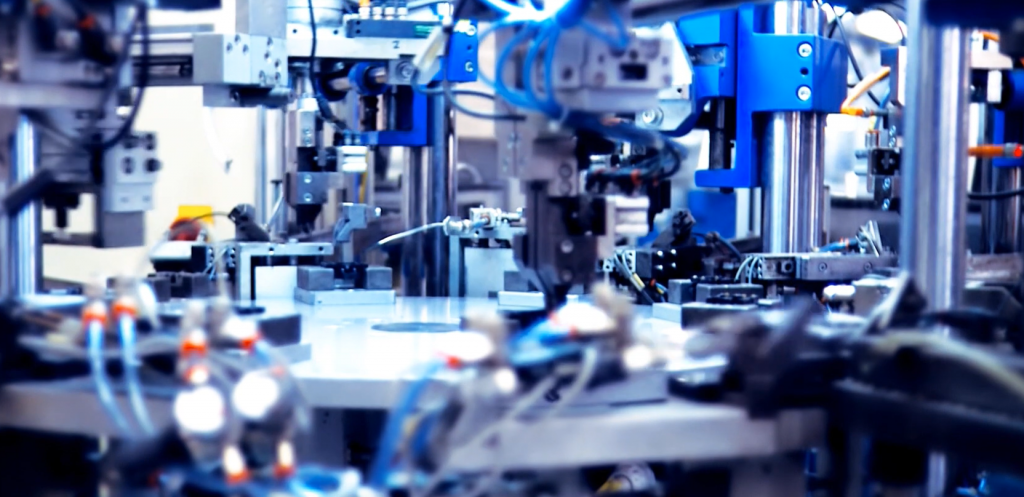

Home & Lifestyle businesses with multiple product lines and complex components or ones about to make the shift from unit to mass production are particularly at risk from bottlenecks. If materials and parts don’t flow through production as they should, then machines will sit idle, workers won’t be able to work effectively and productively, and resources will be underused.

How the Home & Lifestyle industry can overcome this

Manufacturers are always looking for ways to optimize production of their products and components, which can range from unit production up to mass runs of several thousand items. Companies that plan and schedule their production with outdated tools tend to find that their planning and scheduling work is handled individually and isn’t integrated. This means that processes can be manual, static and time consuming.

It is why our customers choose Perfect Production based on DELMIA for short-term Production Planning & Scheduling software to become more dynamic, automated and collaborative. This solution optimizes production flow and allows businesses to handle their planning and scheduling processes seamlessly on one platform. As part of this, they can build an integrated model of their manufacturing constraints at finite capacity.

With Perfect Production based on DELMIA, Home & Lifestyle companies can optimally control their just-in-time production, reduce run times and balance loads across different shops. It means they can plan effectively and anticipate bottlenecks before they occur, leading to three key benefits:

- Financial gains: scheduling is easier and faster to implement. In fact, it can take around a quarter less time than it did before all while reducing in-process inventory and run times to ensure just-in-time production.

- Strategic gains: supply chain levels end up being far more reliable, which means that bottlenecks can be anticipated and corrected before they occur.

- Organizational gains: with fine-level control of all production processes, companies can communicate more effectively with subcontractors and clients and share precise volumes and lead times.

Making the transition from unit to mass production can feel like a big step, especially when complex components are involved. But it doesn’t need to, at least not if you have the right tools in place to ensure your manufacturing processes are dynamic, automated and collaborative.

You too can scale without compromise and hit the mark every time in terms of design and function by building an integrated model of your manufacturing constraints at finite capacity, using demand-driven planning and scheduling all on one single business platform.

So, if you’re looking to bring new products to market faster without compromising on quality, then say goodbye to legacy tools and an outdated modeling approach and embrace a modern demand-driven scheduling solution that gives you total control of your component production.

There’s no time like the present to improve your supply chain service level reliability and gain fine-level control of your manufacturing operations.

Click here for more details on how the 3DEXPERIENCE platform will support your business and turn component complexity into production transparency.