In my last blog post, I wrote about how visibility into real-time manufacturing intelligence can let management improve and enhance Lean manufacturing software programs. This improvement can be accomplished with access to real-time production information, ideally aggregated from across the enterprise. Better, faster access to information allows management to act with greater efficiency, which contributes to improved Lean performance.

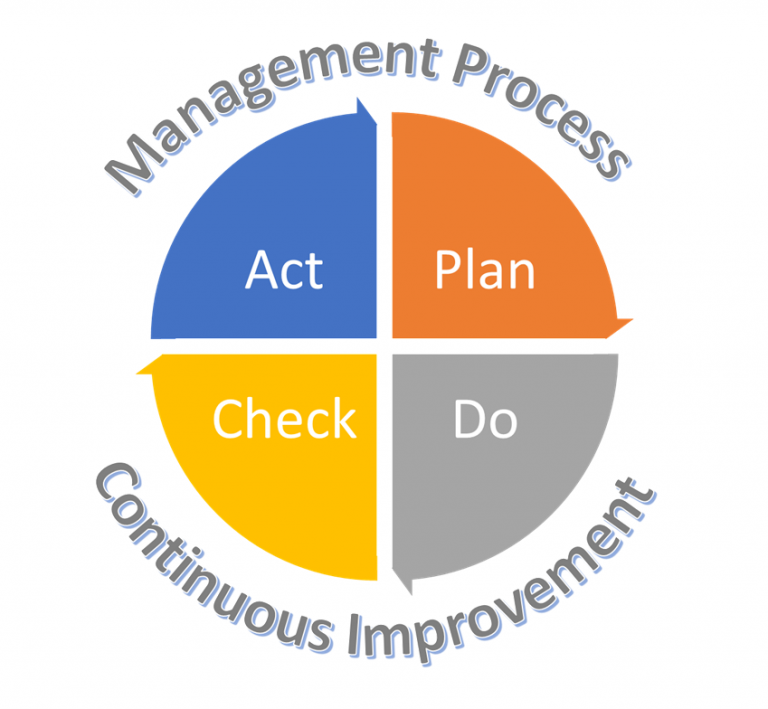

But what if we took the idea even further? What if manufacturers could continuously improve the management process itself, in the same way that they continuously improve a production process?

After all, they are both processes. When something happens in the enterprise that requires judgment and decisions, such as a quality crisis or a market shift, a management process is initiated. Management receives information (or doesn’t), investigates the situation (or not), and takes action (or fails to). Furthermore, there are meaningful metrics involved, such as time to discovery, time to resolution, outcome of resolution, and profit/loss impact.

Looking at Management as a Process

If management decisions affect Lean performance, and if there are metrics that can be tracked, compared, and improved upon, then in theory, couldn’t we use this information to continuously improve the actual management processes? I think the answer is yes.

When a manufactured part begins to trend out of performance, you know this because you are tracking all such parts being produced globally. If one part from one plant is out of spec, you take action. Perhaps you find the plant is not following best practices, so you take steps to correct the problem and deploy the proper processes.

The same approach can apply to management decision-making. If an enterprise tracked how managers performed in these situations, I’ll wager there would be significant differences discovered. Some management teams would accomplish more with fewer resources. Some would resolve problems faster. Some would deploy new processes more effectively than others. These differences could be tracked by an information system—let’s call it a Management Intelligence System.

Management Intelligence System

Suppose, for example, that a particular Lean production initiative was being deployed globally. If we had a Management Intelligence System, we could track and compare how different regions deployed the initiative at the management level. We might find that one region was far ahead of the others in certain key metrics. For instance, we might find that the successful management team accomplished more with fewer resources, but had more regular inter-departmental meetings to facilitate problem-solving.

We could then identify and deploy these management best practices around the enterprise, just as we deploy best production practices.

Is this Concept Possible, or Just Fantasy?

Well, in theory, this type of system could be created using the manufacturing intelligence technologies available today. It would simply require the creation of a new set of metrics—time spent, resources used, departments contacted, etc. This data could be captured by the same system that managers use to investigate production issues, through their computers and mobile devices.

The data is probably there; it’s simply a matter of figuring out how to access and use it.

Let me be clear—I’m not proposing that “big brother” automate the management process. That would be small minded and doomed to failure. Management, by definition, involves human judgment and will never be as cut-and-dried as a production process. But certain elements of management could be measured and improved. What about “Mean time to Resolution?” And if used judiciously and fairly, a Management Intelligence System could yield significant information about how management is performing, and more importantly, where it could be improved.

In other words: Lean management based on continuous improvement.

How about it? Do you think such a system would be feasible, and would you consider it for your enterprise? Leave your thoughts below.