Real-time visibility from a well-connected network

Most communication systems used in A&D tend to be siloes and linear. This impedes transparency, visibility, and ultimately, decision making.

A solution like DELMIA breaks down these barriers, connecting your entire value chain. This gives manufacturers access to much-needed data, key business metrics, and real-time insight into all the fluctuations and changes in the supply chain—allowing better decisions and quicker response times.

In addition, having all the relevant information across the network in real time enables planners to calibrate supply with forecast demand by comparing internal production with real-time demand.

Achieve first-time-right quality

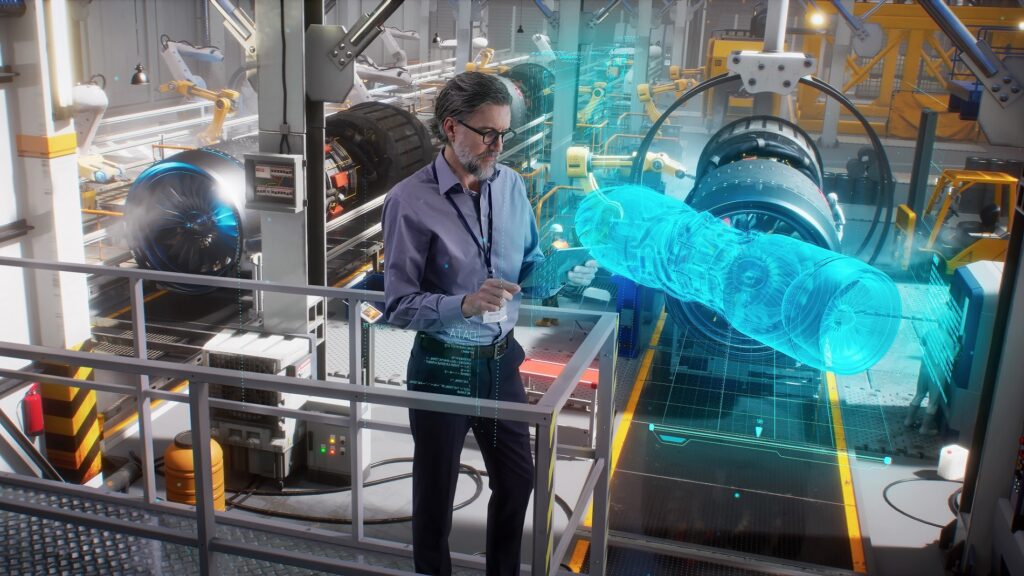

With the DELMIA Virtual Twin Experience, the product as well as the entire factory layout can be modeled and optimized virtually first, utilizing factory flow simulations.

This eliminates the need for expensive and time-consuming physical prototypes for validation and facilitates efficient production before resources are deployed in the real world. Not only does this cut down cost and waste, it also significantly increases the chances of achieving first-time-right quality—shortening the product development cycle.

Besides this, by experiencing the entire workflow virtually first, manufacturers can identify opportunities to arrange equipment in ways that can reduce energy consumption. For example, minimizing the distance motorized vehicles need to travel.

Implement sustainability throughout your value chain

The DELMIA solution also has the capability to consider suppliers’ emissions and transport (including distance and transportation mode) so that manufacturers can gain visibility of a product’s carbon footprint within the supply chain. Planners can then include these factors as constraints when developing a sustainable sourcing strategy to build a sustainable supplier network.

In addition, manufacturers can optimize the processing of material across the company, which is one of the four key opportunities in the circular economy transition identified by the Ellen MacArthur Foundation.

The Proven Value of DELMIA: Hexcel Case Study

Hexcel is an advanced composites manufacturer based in North America. With 23 manufacturing sites globally and over 4,800 employees, the organization had difficulty in finding a common solution for the vast disparity of teams and products.

After implementing DELMIA, they were able to track the raw material used to build a finished product and provide genealogy. Now a well-connected organization, Hexcel was able to handle non-conformances enterprise-wide with built-in integrations and workflow management. Furthermore, they could now keep records for instructions and recording steps completed as part of their preventative and corrective maintenance activities.

Here are some of the values and benefits Hexcel achieved:

- Capturing of “tribal knowledge”

- Optimized processes that led to cost and time savings

- Reduction in scrap and wastage

- Identification of wrong raw materials

- Containment of non-conforming materials

- Optimized scheduling that translated into improved production runs

To learn how DELMIA can help future-proof your organization and gain the benefits of agile manufacturing, download our eBook “Maximizing the Benefits of Agile Manufacturing in Aerospace & Defense” now.

Watch this video to discover more: