A quick question for you

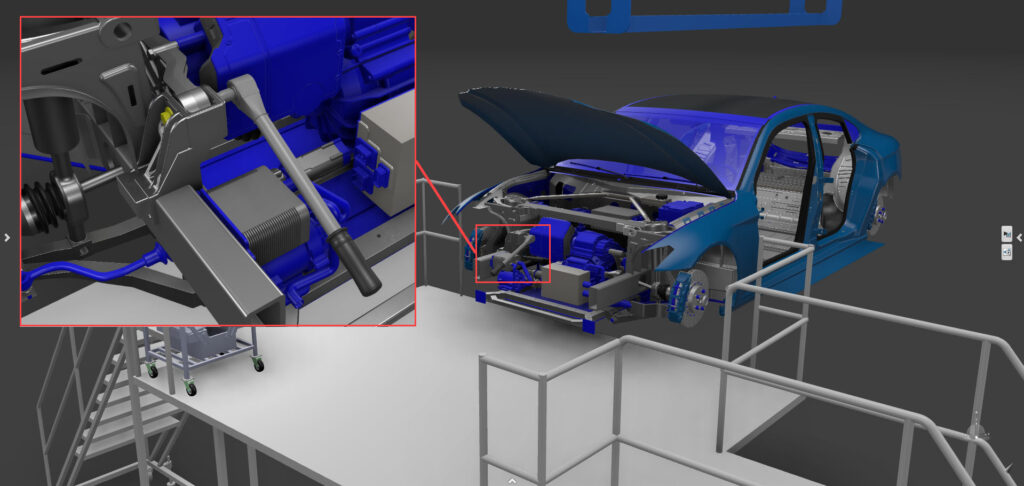

Imagine that you are a manufacturing engineer and you have to evaluate the manufacturability of your workstation in 3D before going live. The image below is the 3D model that you have in order to evaluate the feasibility of tightening a bolt with a torque wrench. You have about 2 minutes to evaluate the worker task. What would you do?

Visualize problems in 3D

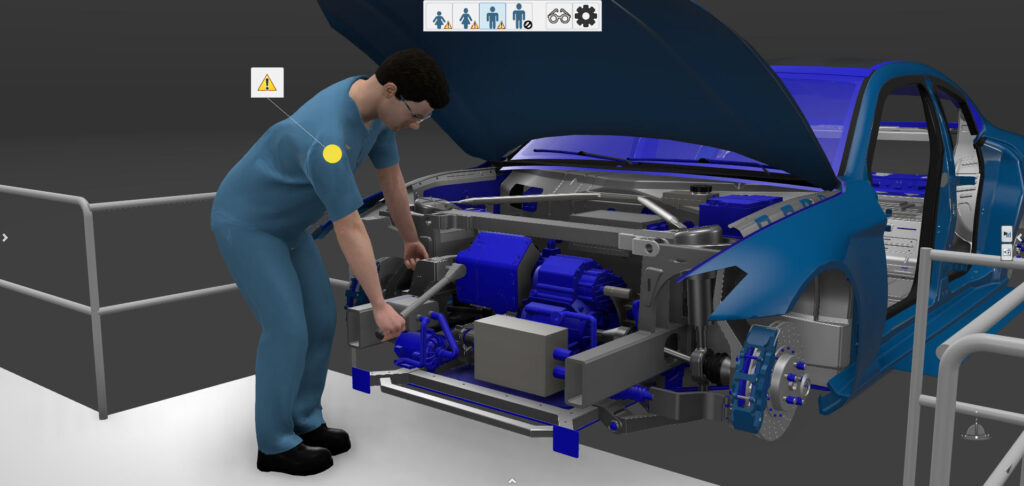

The image below shows the result of what a worker would do for this task. Clearly you can see that there is a problem. The task is too low. The worker bends and this creates movements that are risks for him. This is obvious once you can see a manikin in 3D, right?

Now what would have happened if this task was not detected as problematic? This would have created musculoskeletal disorders for your worker as well assembly quality problem and production speed decrease.

Why ergo software is crucial for automotive

You can see how industrial ergonomics software play a crucial role in the automotive industry. The image displayed illustrates a common issue, where the task is positioned too low causing the worker to bend excessively. This not only poses health risks to the worker but also affects the assembly quality and production speed.

These human factors need to be considered and that’s where ergonomics in 3D comes in. With significant advancements 3D technologies that aid in ergonomic assessments, quick adjustments are possible. For instance, adjusting the height of the task by lowering the floor by 30 cm can make a significant difference in the worker’s posture, thereby reducing health risks.

You can also enhance the precision of ergonomic evaluations, leading to improved workplace safety and productivity.

In the next sections, I’ll explore how these technologies can help to save time and money.

New technologies make it faster

What about assessment speed? How long does it take to have this 3D evaluation? To have this assessment of 4 workers of different sizes, it took 28 seconds.

This is possible thanks to our new posture prediction technology called the Smart Posturing Engine. It is on average 95% faster than any solutions available on the market. New technologies like these not only make ergonomic evaluations faster, but also more precise, which in turn leads to improved workplace safety and productivity. They have proven to be vital in mitigating ergonomic hazards within work environments, enhancing the speed and precision of ergonomic evaluations in the automotive industry. Ultimately, this leads to improved workplace safety and productivity.

Iterate and evaluate quickly

Thanks to the 3D software world and the posture prediction technology, we can also iterate quickly to find a proper height for this task. By lowering the floor by 30 cm, we can relaunch and have a new assessment.

In that case the evaluation only took 13 seconds.

Find out how to save time and money with ergonomics

To learn more about this new application, check out all you need to know on Ergonomic Workplace Design.

Read the DELMIA blog, Maximize Productivity in Automotive Manufacturing with Virtual Ergonomics.

You can also network and grow your knowledge about ergonomics in our Ergonomics Community. It’s free to join.

Listen to our podcasts: