Designers can create the best product in the world, but without production excellence, no company can be profitable. A perfect example, is Tesla that went from $84,000 to $36,000 production cost per vehicle and is still heavily in manufacturing nowadays.

Small mistakes, big costs

In the automotive industry, short-term production planning software is critical. Any small mistake on the plant layout or product assembly can cost a lot. The speed of go-to-market and increasing complexity of the car makes it hard to avoid those mistakes. This is where virtual industrial ergonomics software will save you.

Problems found earlier cost less

In the automotive industry, crucial gates exist. One of most crucial one is called the “tooling go” or “tooling freeze.” This is where decisions are made as to which tools should be used in the line, then ordered with suppliers. Any change to the tools after this gate will cost more money and is to be highly avoided.

This is why, the earlier problems are found and solutions proposed, the more money is saved. The final efficiency of the line will depend of how quickly those problems are found.

3D is the solution

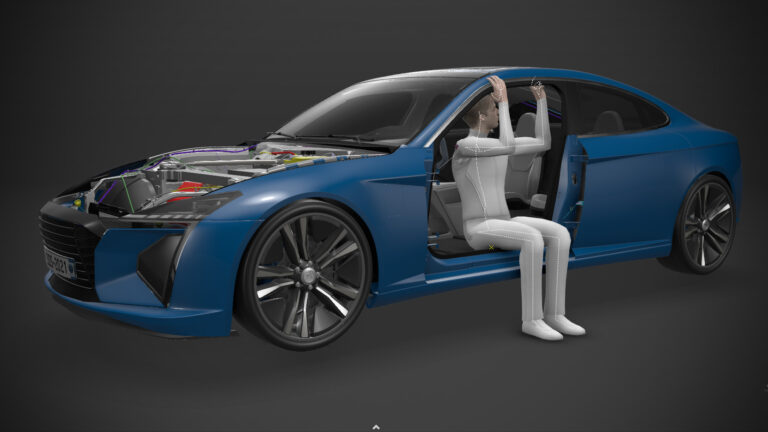

Every car manufacturer designs their product in a 3D CAD software. The good news is that this is the first and main thing that is needed to test your product assembly in 3D.

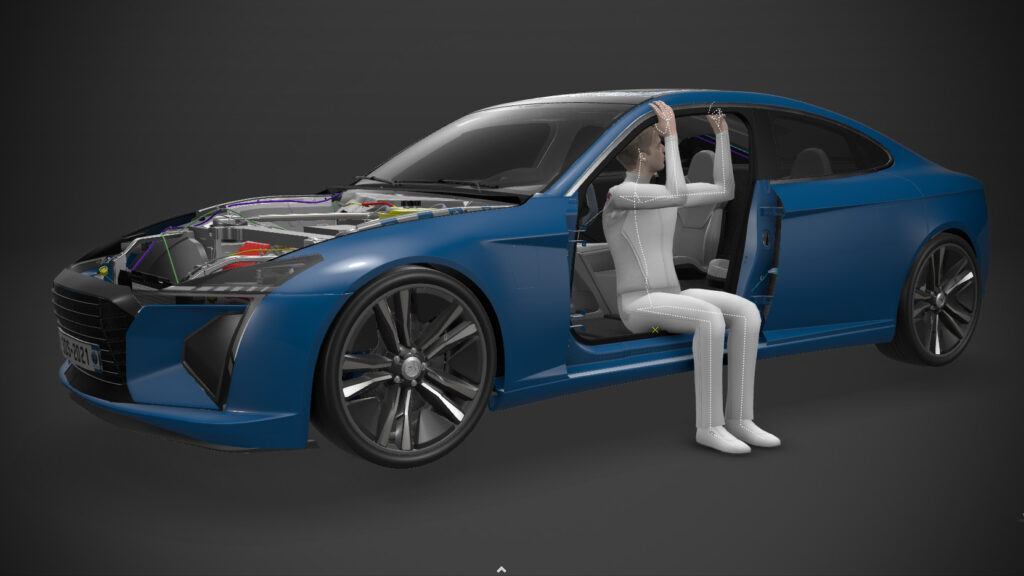

With your product in 3D, you can already conduct reachability studies of parts for your workers in 3D. You can also try to use existing tools that you already have in this early design stage.

Of course, the more detailed the 3D layout is, the more accurate the assembly assessment will be, but you don’t need to have the final line to test it!

Virtual ergonomics apps for fast assessments

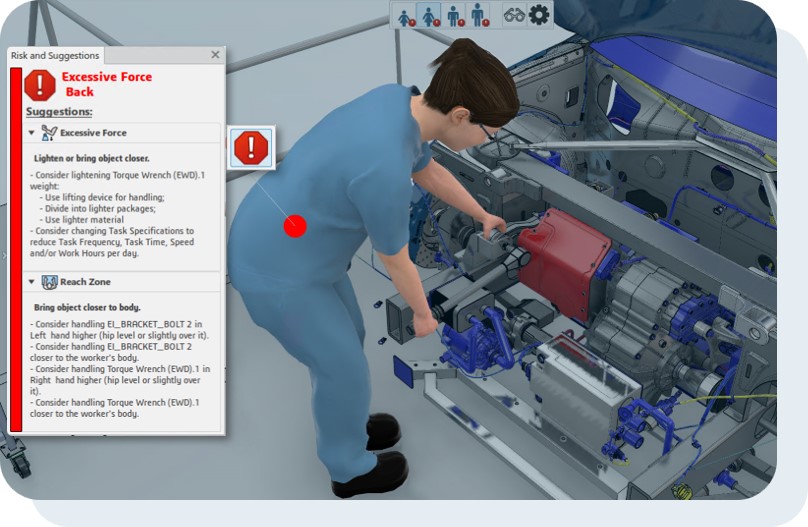

DELMIA offers two apps to help you find assembly problems as early as possible. Our latest is “Ergonomics Workplace Design.” This is perfect for manufacturing engineers that do not have the ergonomics knowledge and want a quick assessment. You can use it to assess the final assembly of the car as well as on sublines.

If you’re more of an expert in ergonomics and want more control over the evaluation, you can use ”Work Safety Engineer.” You’ll be able to choose the standards to use and have more control over the assessment.

Communication is key

At this stage, you might be thinking, “This looks cool, but it’s more complex than my Excel evaluation spreadsheet.” You’re right! It is. Now, the question is how easy is it to communicate your manufacturability assessment to stakeholders with a spreadsheet? How much time have you spent trying to explain a problem that only you can currently see?

By using virtual ergonomics apps, you’ll be able to see in 3D your workers performing the task. This is the perfect way to share your assessment. Everyone, will see the same problem in 3D. You’ll save time and have a shared understanding with your production manager or your ergonomist.

Production efficiency enhanced

If you have a 3D model of your car, you’re ready to use virtual ergonomics apps and enhance your production efficiency. No more endless meetings with stakeholders to review manufacturability problems. Find your problems earlier and communicate them better thanks to virtual ergonomics applications.

Where to go next

Learn more about how DELMIA Virtual Ergonomics software can benefit your workplace by checking out our Ergonomic Workplace Design page.

Listen to DELMIA’s Global Operations on the Go podcast on ergonomics.