Simulating your production line in 3D is a great way to forecast most of the production problem, but it is sometime hard to design an ergonomic layout. This can cause a lot of troubles: archiving tack time, quality issue, Musculoskeletal Disorders (MSD), insurance cost increase and more.

Fortunately, you can avoid most of those problems with a few simple tips!

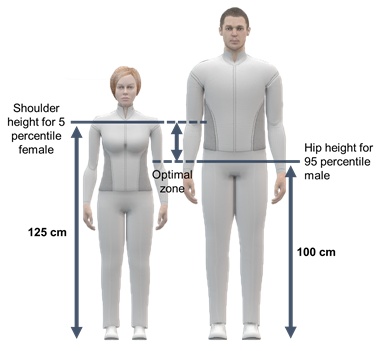

1 – Place Objects at the Right Height

Following ISO 14738 the optimal height to work should be between 100 cm to 125 cm high when standing.

2 – Place Objects at the Right Distance

Once again using the ISO 14738 standard, the maximal distance between a worker and the object to grasp should not access 48.5 cm. For example, a workbench width shouldn’t exceed 48.5 cm to have a safe and more efficient design.

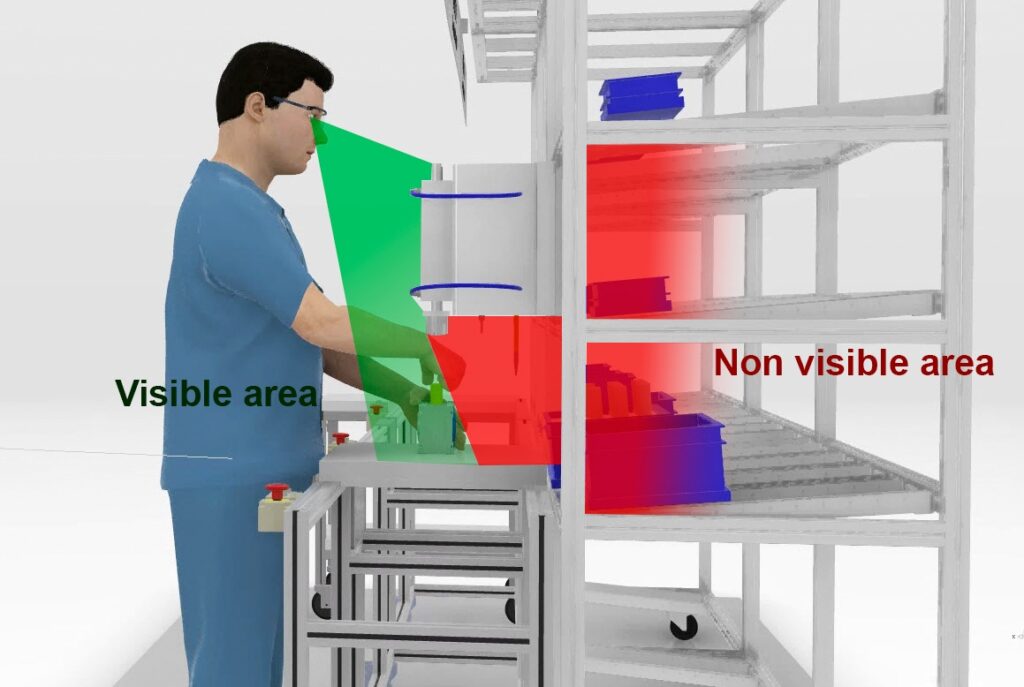

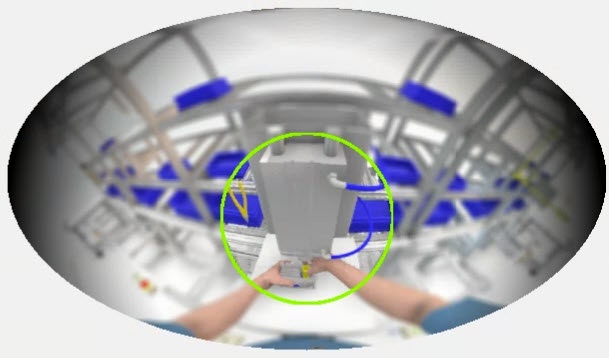

3 – Keep Everything Visible

A worker that cannot see what he is reaching or assembling will result in quality issue and efficiency loss.

4 – Keep Everything Light

What is considered a heavy object?

Using (Mital et coll. 1997) article, an object shouldn’t exceed 27 kg for a male worker and 20 kg for female worker if grasped with both hands.

If grasp with one hand, then the object shouldn’t exceed 16 kg for a male and 12 kg for a female.

However, this weight limit is very high and is only valid for tasks that are not repeated often and under certain condition. To know what should be the object weight in your context, you should consider a lot of parameters like:

- The task frequency

- The task duration

- The task velocity

- The action time

- Internal joint momentum

- The body posture

In conclusion, let say that you would need an ergonomic degree and have a lot of time … or you could use Ergonomic Workplace Design software which does that automatically for you in one click.

With those few tips, you’ll be able to avoid a lot of ergonomic problems and make your production line way more efficient.

If you want to avoid event more problems, you can also use Ergonomic Workplace Design. This app will automatically analyze the industrial ergonomics software of your production line thanks to its posture prediction algorithm.

Learn more about Ergonomic Workplace Design and how you can save money to your production line here.