This article was originally published in the June 2019 issue of SIMULIA Community News magazine. Learn how French start-up company XSun adopts Dassault Systèmes cloud-based solutions for its design and simulation needs.

If Benjamin David has anything to say about it, the term “bird’s eye view” is about to take on a much broader meaning. The chief executive officer and founder of XSun in Guérande, France, Benjamin is developing the next generation of UAV (Unmanned Aerial Vehicle), more commonly known as a drone. But where most people associate drones with battlefield reconnaissance and peeking into the neighbor’s backyard, Benjamin is designing costefficient, autonomous flying machines that give farmers better real-time crop knowledge (smart agriculture), help fishermen avoid the capture of unwanted species (smart fishing), and aid fire crews in putting out forest fires (environment protection).

It’s nothing new to Benjamin, who has spent the better part of two decades looking for better ways to look down at the Earth. After graduating from Polytech Nantes in 2001, he served internships with the Centre National d’Études Spatiales (France’s National Centre for Space Studies) and then the European Space Agency (ESA). He went on to work for Airbus Defence and Space, first as a flight engineer with the British military’s SKYNET5 project, followed by site manager responsible for control systems on the ESA’s Galileo satellite constellation.

In 2016 he embraced a new challenge. Together with a team of engineers and technical advisers, Benjamin built a company that has a unique vision: to deploy a fleet of smart solar-powered UAVs capable of staying aloft for days, weeks, or even months. What’s more, these drones will be autonomous, without the need for human guidance, and carry a host of sensors and cameras able to map, monitor, or measure virtually any point on the Earth’s surface below. “It is a plane inspired by satellite design, except that it won’t be expensive to launch,” he explains. “It will use the sun’s energy to charge a set of onboard batteries, just like a satellite does, and perform many of the same functions. That is our goal.”

“The 3DEXPERIENCE platform on the cloud is a very deep resource, with capabilities we haven’t even touched yet.” —Andrea Viti, Aerodynamic Engineer, XSun

JOINING FORCES WITH DASSAULT SYSTEMES The tools XSun uses to make this dream a reality? The cloudbased 3DEXPERIENCE design and simulation platform. “We needed a multidisciplinary engineering software solution that could support material structures, aerodynamics, the electrical systems and energy consumption—pretty much everything needed to get an aircraft off the ground and keep it there for long periods of time,” Benjamin says. “Based on my experiences at Airbus, I knew that CATIA and SIMULIA would be part of that solution.”

Benjamin’s team applied for and was accepted into Dassault’s 3DEXPERIENCE Lab, an accelerator program designed specifically for startups like XSun. The Lab supports and nurtures cutting-edge companies through a network of collaboration, innovation, and leadership, sponsoring projects that include robotic wheelchairs, energy-producing seaborne membranes, 3D-printed electric violins, and asteroid-hunting telescopes that could one day save the human race from extinction.

“I was very happy to be included as part of the 3DEXPERIENCE Lab,” says Benjamin. “Although access to a suite of excellent software tools was quite important to us, there was much more to it than that—there was the mentoring we received, the training and events we were invited to, and the possibility of sharing ideas with other entrepreneurs. It’s been a really good experience for us.”

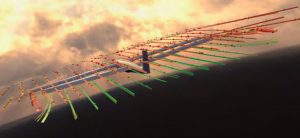

AUTONOMOUS FLYING MACHINES Though the XSun team continues to put the finishing touches on their revolutionary UAV—dubbed the SolarXOne—they are understandably proud of the seventeen missions flown thus far, with more in the works. Their double-wing design boasts a 4.6-meter (15 ft.) wingspan, a length of 2.6 meters (8.5 ft.) a total mass of less than 25 kilograms (55 lbs.), and carries an impressive display of instruments, including a high-performance camera, infra-red imaging capabilities, and a “miniaturized hyper-spectral” sensor for measuring soil composition and other tasks. There’s also an onboard LIDAR (Laser Imaging, Detection And Ranging) able to create highly accurate digital 3D-images of the terrain and structures below.

The final capability to be launched is the solar part of the equation—the SolarXOne is currently powered by rechargeable batteries—and Benjamin says that’s about to change. “The SolarXOne is able to fly for extended periods on batteries alone, but our next prototype will charge those batteries in flight, using power from the sun. Once that milestone is reached, I anticipate it won’t be long before we deploy a larger fleet of autonomous machines with more and more capabilities.”

Whatever you call it, Benjamin says their UAV isn’t all that different (at least in structural concept) than the world’s first heavier-than-air powered aircraft—the Wright Brothers’ Flyer I, which took to the skies over Kitty Hawk, North Carolina in 1903.

But where the now-ancient Flyer’s wings were positioned one above the other, the SolarXOne carries wings both fore and aft. This tandem wing design provides larger surface for the solar array than is otherwise possible, and therefore more potential electrical power. Having two wings provides aerodynamic benefits as well, such as greater stability in rough weather, and makes it easier to attain a lower aircraft weight for a given amount of lift—by comparison, the Wright Brothers’ plane had a wingspan of 40 feet and weighed more than 600 pounds.

“Most UAV designs favor a single ‘superwing’ approach, so we are unique in this respect,” notes Benjamin. “That said, finding the right proportions was challenging. At one point we found it easiest to just go back to square one and begin with a blank page. CATIA and SIMULIA helped us in this respect, as we were able to test many iterations very quickly. Our current design was the result.”

LOOKING TO THE CLOUD Aerodynamic engineer Andrea Viti is part of XSun’s dronebuilding team, a team that spans multiple countries and continents. Like his boss, he’ll tell you that Dassault’s 3DEXPERIENCE cloud capabilities have made collaborating with people hundreds or even thousands of kilometers away much easier and more productive, never mind the fact that both are big fans of the software.

“We are doing design work that is quite simply mindnumbing,” Viti says. “The surface quality, the aerodynamics, the overall geometry of each component—everything has to be perfect or the aircraft won’t fly. CATIA does that for us. It’s used all over the world, especially by those with missioncritical requirements like ours. I think it’s the best 3D CAD product available.”

Realistic simulation is also critical. For this, Andrea and his colleagues rely on the SIMULIA software portfolio within 3DEXPERIENCE. The ability to model their craft using different materials, test various wiring configurations, model wind flow and check structural integrity—these are just a few of the design-engineering functions made available to them working with the 3DEXPERIENCE Laboratory. “Designing this aircraft is a huge task,” says Andrea. “It’s been very important to have very good software to address all the multiphysics involved.”

The team soon realized that heat dissipation and turbulence were important areas to focus on. In each case, SIMULIA tools helped them determine the optimal design, and understand the performance of each design iteration, thereby minimizing the need for physical testing. With the tight integration between CATIA and SIMULIA, simulation models were updated automatically with each new design revision.

“The 3DEXPERIENCE platform on the cloud is a very deep resource, with capabilities we haven’t even touched yet,” Andrea says. “It’s been extremely helpful to have this kind of multidisciplinary analysis available to us, plus the fact that we can collaborate on problems over long distances, even by smart phone or tablet. And in those instances where we run into something we can’t figure out, Dassault is there to mentor us. All in all, it’s been a really nice solution.”

PREPARING FOR LAUNCH Benjamin is anticipating the further evolution of his prototype. His long-range plan is to build a fleet of drones, a centralized control center (and ultimately, more than one), and for XSun to offer services to whomever needs relatively low cost, realtime surveillance, analysis, and digital mapping of both land and sea; where an airplane or helicopter will cost many thousands of dollars per flight, he says, XSun’s will be much more competitive.

“Our operational costs will be much lower than any of the other UAV solutions out there, and we’ll have greater flexibility as well,” he says. “I encourage anyone looking for this type of service to give us a call. Now that we’ve arrived at a mature design, we’re definitely looking for new business opportunities.”

His aerodynamic engineer agrees that the base design is optimized and ready to start chasing the sun. “The nice thing about the tandem wing is that it’s very flexible yet stable—even more stable than conventional aircraft,” says Andrea. “Thanks to the 3DEXPERIENCE platform, we proved that it can work in a variety of weather conditions and terrains and, once the solar panels are installed, we’ll be able to stay aloft for as long as is needed. It’s flying well.”

For More Information: https://3dexperiencelab.3ds.com/en/projects/life/xsun