The competitive world of professional soccer is surprisingly quite similar to the automotive industry’s competitive world of electric vehicle battery production. In a soccer match, teamwork is an essential collaborative effort from athletes to join forces and battle against the best teams in the sport for the title of champion. Similar to soccer teams, EV automotive companies must work in a collaborative team effort with partnering specialized companies to release the best engineered batteries and electric vehicles to date. Just as coaches train athletes into top-notch fitness to perform under pressure and win game-after-game; Dassault Systèmes is here to help companies throughout every step of the car battery engineering process, to get fit and reach top-notch performance with championship winning electric vehicle releases.

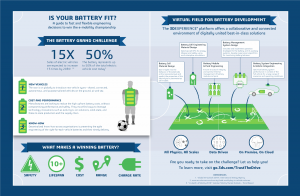

The automotive playing field is currently experiencing industry advances with new vehicle-type additions as OEM’s pursue alternative technologies to that of the gas-powered vehicle. Consumers are seeing more shared, connected, autonomous, and purpose-tailored vehicles on the ground, air and sea. Electric vehicles lead the way in new vehicle-type additions with EV sales projected to increase 15 times by the year 2030. Fans of electric vehicles will be able to see the car-type go head-to-head with the defending champions, gas-powered vehicles, as OEM’s release new and improved EV models.

View the Infographic: Is Your Battery Fit?

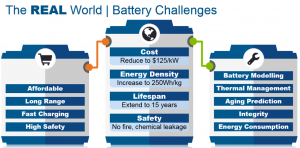

In order to produce game changing EVs to market, manufacturers are strategizing to reduce the high upfront battery costs, without compromising performance and safety. Manufacturers must find ways to leverage battery technology innovations, such as the evolving li-ion and the emerging solid-state solutions, to scale to mass-production and the supply chain. Competition remains in discovering advances to the EV battery, as the battery represents up to 50% of the total electric vehicle cost today.

In understanding how to improve the battery and cut costs, we must introduce the five major players that work together in battery development. Beginning with the battery cell material designer, this player gains insight into the behavior of the electrode at the nanoscale level and predict the properties of the electrolyte to parameterize cell models. Second, is the battery cell engineer, that optimizes cell KPIs for energy, lifespan and safety using multi-discipline simulations. Third, is the battery module & pack engineer, that ensures structural integrity and optimal thermal management of battery module and pack. Fourth, is the battery management system designer, that simulates and implements operation strategies for the battery and its auxiliary systems, in addition to developing supervision algorithms for monitoring battery behavior. Finally, the last and fifth player is the battery system engineering & vehicle integrator, that optimizes battery system performance in context of the full vehicle for a large range of scenarios and operating conditions.

This team must work closely together to create batteries that meet today’s performance expectations in battery safety, longevity, cost, charge mileage range, and charge time. Customers expect electric vehicles to be sold at affordable prices, cover a long range, charge quickly, be regarded as safe and last as long as the traditional gasoline cars. Dassault Systèmes can help coach the battery engineering and design team, to reach customer expectations while solving anticipated problems that arise in various car development scenarios. Examples of common engineering tasks Dassault Systèmes can seamlessly solve are:

- Discovering chemistries for safe long-lasting batteries on a molecular level to optimize materials with BIOVIA

- Predicting the performance and aging process of the battery at the system level, from the cell to the context of the entire vehicle with CATIA Systems

- Optimizing thermal management, fire safety, overheating and energy efficiency of the EV battery with SIMULIA

- Anticipating how well the battery will integrate with other systems of the vehicle with CATIA and the recent acquisition of NoMagic at the system level (e.g., Electric drive, HVAC and car electronics), and SIMULIA at the fully detailed model level (e.g. crashworthiness, vehicle dynamics)

CATIA, BIOVIA, SIMULIA and NoMagic can discover solutions for performance assessment in areas of battery cells, modules and packs; materials and chemistry modeling; and mechanical and system design. Dassault Systèmes is looking to take EV battery teams to the championship, utilizing the science of the digital world to offer specialized engineering solutions.

Dassault Systèmes can take on the challenge. Visit: go.3ds.com/TrustTheDrive to learn more.

References

- “Global EV Outlook 2018”, International Energy Agency

- http://www.ev-volumes.com/country/total-world-plug-in-vehicle-volumes/

- “In-depth: eMobility 2018”, Statista Mobility Market Outlook – Trend Report

- https://www.energy.gov/sites/prod/files/2014/02/f8/eveverywhere_blueprint.pdf