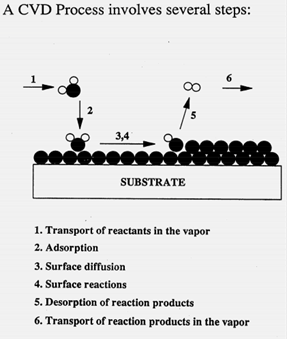

Chemical Vapour Deposition, CVD, is one of the oldest techniques for growing metallic films. As Karin Larsson tells us in her excellent monograph “Chemical Vapour Deposition: Growth processes on an atomic level”, the CVD growth of tungsten was first reported as far back as 1855. The CVD technique is continuously gaining importance and the range of applications extends now to electrical, optoelectronic, optical, mechanical, and chemical. Nowadays, CVD is also used to produce multilayer films for creating multifunctional materials.

Naturally, this expansion in the functionality of CVD–grown thin films required new efforts in the characterization of thin films and in the simulation of the relevant processes. Atomistic-level information is invaluable for understanding growth processes and ultimately improving the characteristics of the final product. Such knowledge usually comes from quantum mechanical calculations, typically at the density functional theory (DFT) level. DFT is the most practical approach to atomistic studies of CVD, combining speed and accuracy to gain insight and build multiscale CVD reactor models. The expansion of CVD techniques to new classes of materials means that very often there are no reliable chemistry models, so an atomistic approach is required to describe surface reactions. DFT studies explain the basic mechanisms of atomic assembly and provide energy barriers and reaction rates for macroscopic studies with kinetic Monte-Carlo or similar tools.

Until recently, this critical field lacked a reliable, down-to-earth, practical description of atomistic simulation techniques. Professor Karin Larsson’s new book is an excellent resource that effectively addresses the lack of practical descriptions of atomistic simulation techniques in the field. With this book, researchers and practitioners can now have access to a reliable and comprehensive guide for applying these methods in real-world scenarios. Karin has a long history, more than thirty years, of CVD growth modeling at Uppsala University in Sweden. Prestigious election to IVA (Royal Swedish Academy of Engineering Sciences) recognizes her work in this field. The use of BIOVIA software such as Materials Studio and in particular, DFT solvers DMol3 and CASTEP, is essential to support research projects in Professor Larsson group.

The book “Chemical Vapour Deposition: Growth Processes on an Atomic Level” is available from the publisher in various formats. From a theoretical perspective, Karin’s work on CVD is summarized, and it relies entirely on calculations performed using Materials Studio. As the author says, this is intended to be “an instrumental book of instructions for the practical handling of theoretical methods in the course of the calculations.”