Businesses are working to reduce their impact on the environment and are aiming for more sustainable business models by redesigning their product lines and manufacturing systems. For example, Apple is using 100% recycled aluminum for the enclosure of the Mac Mini and MacBook Air, cutting the carbon footprint of these products by almost half. To drive sustainability AND innovation, companies need to integrate eco-design principles in the upstream thinking, before their products and processes cause any environmental impact in the real world.

This is where Lifecycle Assessment (LCA) – a comprehensive method to measure the environmental impact of a product throughout its entire lifecycle – fits. LCA helps manufacturing companies improve their sustainability performance, reduce costs and risks, and enhance their Environmental, Social, and Governance (ESG) reputation.

While extremely valuable, LCA is also a process that requires specialized knowledge and expert resources. For these reasons, companies have limited LCA to important projects or annual reporting of past impacts. However, with the help of digital technology, LCA is quickly becoming a more accessible and valuable tool for businesses looking to improve their sustainability practices. In this post, we will look at:

- Sustainability drivers leading to LCA adoption

- Challenges implementing LCA

- LCA and virtual twins

- Benefits

Sustainability Drivers Leading to LCA Adoption

LCA has gained in popularity when evaluating environmental consequences. Let’s review the sustainability drivers leading companies in all industries to adopt LCA as a regular practice.

- Customers – Customers are demanding products and services be more aligned with their beliefs and values. This is especially true with younger consumers (age 18-39). 53% consider “providing credible green credentials, minimizing harm on environment, investing in sustainability” a fidelity factor. (Source: Accenture; Generation P(urpose)).

- Investors – ESG investing is on the rise. A Harvard survey found that 81% of institutional investors in the US plan to increase their allocations to ESG products over the next two years, almost on par with Europe (83.6%). To match those priorities, companies will have to alter their mode of operation.

- Employees – In a recent Kite insights survey of 7,000 employees in 15 industries across the world, 55% said their company has an important role to play in tackling the climate crisis. 83% said they are ready and willing to support climate action in the context of their work. Employees want to take pride in their workplace and they want their organizations to take environmental concerns seriously.

- Regulations – Regulations are an important lever if we want to reduce our impact on the environment and achieve the goals set in the Paris Agreement – 45% emission reduction by 2030; net zero by 2050. Business leaders understand this new reality: More than 3,000 businesses are working with the Science-Based Targets Initiative to reduce their emissions in line with climate science.

Challenges Implementing LCA

Lifecycle assessment is a comprehensive and systematic approach. It requires detailed information on the product’s material and energy inputs, emissions and waste streams, which can be challenging to obtain, especially during the early stages of product design. Designers and engineers must also consider the variability in environmental conditions across different regions. For example, should the assumptions made for North America be different from the ones made for products intended for Southeast Asia?

Additionally, LCA can be a time-consuming and resource-intensive process, requiring specialized knowledge. The cost of conducting an LCA may be prohibitive for small or medium-sized enterprises, and some organizations may not prioritize sustainability practices in their product design. Despite these challenges, LCA is a valuable tool for reducing the environmental impact of products and promoting sustainability in manufacturing industries.

How LCA adoption can be facilitated in small and big enterprises:

- Make LCA part of the innovation cycle, fully integrated with design and simulation solutions

- Provide a LCA database that supports environmental assessment of products and processes worldwide and interoperable with modern software solutions

- Foster and facilitate collaboration between the different teams and stakeholders from across the enterprise and disseminate LCA insights.

LCA and Virtual Twins

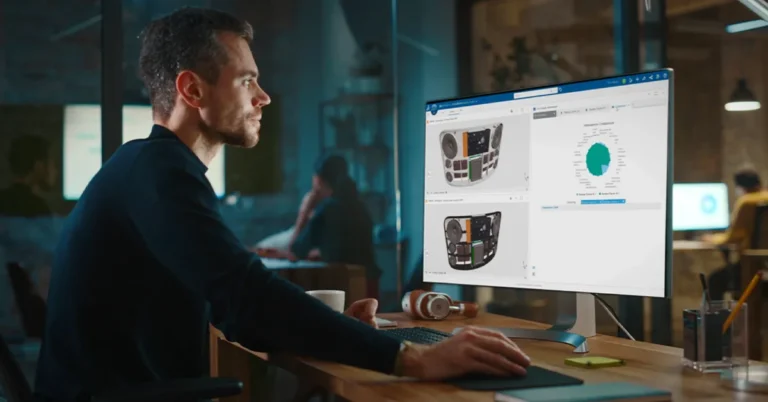

A virtual twin starts with designing a 3D model that represents the shape, dimensions and properties of a physical product or system. Simulations are run on virtual models to explore how the product will behave when assembled, operated or subjected to a range of events and conditions. By providing a virtual environment to design, develop, test and manufacture that embeds LCA, companies see and assess the impact of their choices before they become a reality.

By integrating LCA into the virtual twin, companies evaluate the environmental impact of a product at every stage of its lifecycle, from raw material extraction to end-of-life disposal. This integration allows for better decision-making throughout the product development process, enabling companies to make more sustainable choices without incurring the costs of physical testing and iteration. For the consumer packaged goods industry alone, by applying LCA at the design stage the GHG footprint reduction is estimated at 7.2%. Visibility into the options available for material, processes, packaging, etc. is in real-time. No more delay or exhaustive analysis.

For manufacturers, integrating LCA and their product development process into a virtual twin also provides a competitive advantage beyond the design and engineering departments. Integrating LCA into the virtual twin provides visibility into the decisions affecting sustainability of the entire company. In other words, the virtual twin makes environmental data and LCA insights more transparent. This multiplies the opportunities for making sound, sustainable choices.

Benefits

Pairing LCA with virtual twins transform the sustainability process and provides several benefits to businesses:

- Identifying opportunities for product optimization: The LCA-virtual twin solution provides insights into the environmental impact of a product and identifies areas for improvement, such as reducing energy consumption, minimizing waste, or using more sustainable materials.

- Acting on the opportunities: Designers and engineers immediately act on the results of the lifecycle assessment by providing new design alternatives – from concept to detailed design.

- Meeting regulatory requirements: Many jurisdictions have regulations in place that require businesses to report on the environmental impact of their products. The solution helps businesses meet these requirements by providing a standardized methodology for assessing the impact of their products.

- Enhancing brand reputation: Consumers are becoming more environmentally conscious and increasingly choosing products that produced in an environmentally sustainable manner. The LCA solution helps businesses improve their sustainability credentials and enhance their brand reputation.

- Reducing costs: By optimizing product design and manufacturing processes, businesses reduce energy consumption and waste, which results in cost savings.

Conclusion

In conclusion, having LCA integrated in a virtual twin benefits manufacturing companies by making LCA more feasible, reliable and useful for sustainability decision-making. This enables them to optimize their environmental performance while reducing costs and risks.

Learn about the implementation of eco-design methods in product development and the integration of LCA into the design and development of more sustainable products by watching Dassault Systèmes series of 3 webinars.