What if you could crash a car and analyze it … without actually crashing a car?

Sounds impossible? Well, taking a MODSIM approach, you can keep both your data and your car intact.

MODSIM, a unification of modeling and simulation, breaks down the silos between design and analysis, putting the power of virtual testing in the hands of designers. A MODSIM approach powers your personal smart workshop and virtual test lab, harnessing the power of AI to accelerate innovation in engineering workflows. Equipped with a memory bank that replicates previously designed elements with just one click, it’s an approach that works for you. Powered by the 3DEXPERIENCE platform on the cloud, the flexibility of cloud computing gives you the power and space you need, when you need it. MODSIM integrates CAD tools such as CATIA and SOLIDWORKS with simulation tools from SIMULIA, allowing you to take your design geometry and immediately start testing it without a single physical prototype.

The machine learning algorithms integrated into the platform can predict performance and analyze design changes, redirecting time spent on error checking toward innovating. With AI crunching through massive amounts of data, MODSIM allows you to quickly synthesize information into precise predictions, without needing to be a simulation specialist or a machine learning expert. Want to hazard a guess on how long it takes to provide that feedback?

Nope, not days, but within minutes. All without a sunk cost into hardware resources that are only needed occasionally.

Born from Dassault Systèmes’ 3D universes, a reimagination of real-life representations by blending modeling, simulation, data science, and AI-generated content, MODSIM unlocks the power to create virtual twins of virtually anything.

Whether you’re putting together a highly sophisticated aircraft or analyzing a high-stakes medical procedure, MODSIM is your best friend in getting the job done right. These 9 companies can attest to that.

Premekon

Ever wondered who builds those colossal support structures at manufacturing sites? Chances are, they come from Finland-based firm Premekon, the manufacturer’s manufacturer. Specializing in industrial service platforms, safety is a non-negotiable for Premekon. Every structure is designed to meet the EN 14122 series of European standards, ensuring safe access to machinery. Using parametric models, the company replicates proven, reliable designs and customizes them for each client’s unique needs. Now, Premekon is exploring integrating MODSIM into their design process, aiming for a workflow that’s just as robust as the steel structures they make.

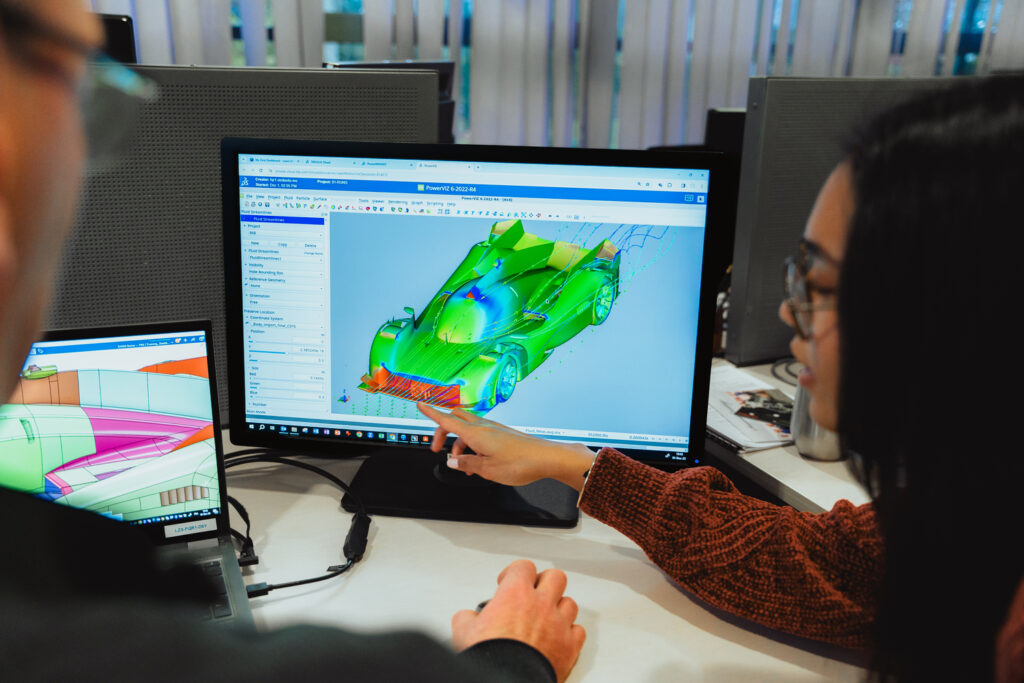

Peugeot Sport

What does it take to reach over 330km/h on the legendary straights of the 24 Hours of Le Mans circuit in France? For elite hyperclass drivers, it’s a combination of driving prowess and engineering brilliance. Peugeot Sport’s 9X8 is evidence of that. Sporting a 2.5-litre, twin-turbocharged 520 kW V6 engine, this sleek beast was born to burn rubber. With an additional 200 kW electric motor driving the front wheel, the 9X8 is able to transform into a four-wheel-drive. Who said endurance needs to be sacrificed for speed? The 9X8 has both. Watch how MODSIM turbocharges Peugeot Sport’s design process to fuel their need for speed.

Unbrick

How does one construct on a piece of land while leaving it untouched? That sounds like an oxymoron, but not for Netherlands-based construction firm Unbrick. One of the select few construction firms permitted to build in Natura 2000, Europe’s network of protected lands that houses its most valuable and threatened species and habitats, Unbrick is trailblazing a path towards greater sustainability. By reimagining every step of the construction process with MODSIM, Unbrick is setting a new precedent for sustainability in the industry. From earning Europe’s highest accolade for energy efficiency, the A++++ label, to pioneering a building process that eliminates nitrogen emissions, Unbrick is proof that construction and conservation don’t have to be mutually exclusive.

HD Hyundai Xitesolution

Imagine if infrastructures could be constructed from the comfort of one’s office or home. No need for long commutes to construction sites or enduring the scorching sun. Nope, that’s not something out of a sci-fi comic, but a reality being shaped by Korea-based industrial equipment manufacturer, HD Hyundai XiteSolution (HDX). By developing remotely controlled autonomous construction machinery, HDX is empowering workers to perform manual tasks without lifting a finger. These robots take over the arduous functions of site building, reducing the risk of on-site accidents while making 24/7 operation possible. The driver accelerating HDX’s ambitions of creating virtual-twin-powered autonomous heavy machinery? You guessed it: MODSIM.

HORYZN

With every minute that ticks by, the survival rate of an out-of-hospital cardiac arrest decreases by approximately 10%. Yet, the arrival of an emergency vehicle could be delayed for up to 20 minutes. That is far too long. A group of students from HORYZN, part of the NEXT Prototypes e.V. Association, a non-profit student organization at the Technical University of Munich (TUM) in Germany, wants to change that. HORYZN’s electric vertical take-off and landing (eVTOL) fixed-wing drone can drop a defibrillator at an emergency site twice as fast as an ambulance on the road, increasing the survival chance of a patient suffering from a cardiac arrest by up to three times. Discover how HORYZN is using MODSIM to deliver defibrillators and restart hearts when every second matters.

CSADI

China’s Central-South Architectural Design Institute (CSADI) is in the business of construction, but with a twist. Inspired by a cyclone, the Wuhan Next Generation Meteorological Radar tower serves as the nation’s central meteorological disaster monitoring network and sports a double-spiral facade. To determine the perfect rotational angle of the building and accurately calculate the shape and dimensions of over 1,000 glass-fiber reinforced concrete exterior wall panels, the coordination of over 10 disciplines from water and heating to electricity and geotechnical engineering is required. Bringing all these components together and taking into account all external physical stressors on the building takes a powerful tool. That’s why CSADI chose MODSIM.

Tree Composites

What if the secret to stronger offshore wind turbines was hidden in a 300-year-old tree? That insight led to Tree Composite’s wrapped composite joint, an innovation inspired by how trees naturally grow around support structures. Developed at Delft University of Technology (TU Delft), the design replaces traditional welded steel joints with composite wraps that significantly extend fatigue life span while reducing steel wastage. To bring this nature-inspired breakthrough to life, Tree Composites turned to MODSIM to simulate every detail required to create lighter, durable turbine parts for a more resilient offshore energy future.

Electrum

What if you could cover long distances on an electric motorcycle without needing to find a charging station? That’s what Electrum, an EV brand created by Indonesian firm PT Energi Kreasi Bersama, wants to make possible. With over 63.3% of commuters in Indonesia’s capital city, Jakarta, relying on motorcycles for their daily travels, Electrum’s swappable battery design removes range anxiety, allowing riders to seamlessly exchange depleted cells and journey on. Their vision is electrifying Indonesia’s shift to sustainable transport and to ultimately achieve its vision of net-zero carbon emissions by 2060. Enabling the dream of a cleaner ride is MODSIM, simulating and optimizing every component of the bike for a cleaner ride.

University of Southern Queensland

Stronger, lighter and more durable than metals like aluminum. What’s not to love about composite materials? Their superior strength-to-weight ratio can boost an aircraft’s fuel efficiency by up to 25%, making them a game-changer in the aerospace industry. However, composite materials come with a challenge: their complex fiber patterns make repairs tough and time-consuming. The University of Southern Queensland’s Centre for Future Materials, a leader in advanced composite materials and manufacturing research, wants to change that. Using MODSIM on the 3DEXPERIENCE platform, their PhD student researchers have found a way to optimize the repair process, improving accuracy and efficiency while minimizing resource waste. And backing up this project is MODSIM, model-simulating solutions, so innovation can take flight.

MODSIM: A fundamental shift in how enterprises approach innovation

By breaking down traditional barriers between design and analysis, a MODSIM approach empowers teams to test, iterate and perfect their ideas in 3D universes without the constraints of physical prototypes or lengthy development cycles.

The evidence speaks for itself. From Peugeot Sport achieving championship-level performance to HORYZN saving lives with emergency drone delivery, MODSIM delivers measurable results across diverse industries. Whether you’re building sustainable structures with Unbrick, developing autonomous construction equipment with HD Hyundai XiteSolution, or optimizing wind turbine components with Tree Composites, this integrated approach transforms complex challenges into streamlined solutions.