Google recently announced Genie 3, which it calls a “world model” that allows users to input prompts to generate virtual video game-like experiences. The initial excitement is understandable: until now, generative AI imagery has left much to be desired, and Google’s latest release not only improves upon that trend but makes it interactive and consistent over long horizons, too.

The name of the tool, Genie, is a portmanteau of Generative Interactive Environments. Its most popular use case skews toward video game users. It essentially builds upon the metaverse concept, providing an immersive, almost physical experience for the digitally plugged-in. At the moment, it’s only available to a select number of testers and a full public release date hasn’t yet been announced.

The development is commendable and represents just the latest iteration of virtual technology in the digital age. But what else can this technology do, and what could its wider availability mean for the world?

The purpose and impact

Virtual worlds have existed for years. Ask a group of people what that term means and you’ll get a few different answers, from references to the metaverse and crypto to digital replicas of products, processes and places, more commonly known as virtual twins.

The former is more targeted toward consumers, while the latter has a specific business focus. Scientifically accurate virtual twin technology, Dassault Systèmes’ flagship offering, is used by tens of thousands of the world’s largest and most successful companies. By building, testing, modeling, simulating and deploying virtual twins in a cloud-based environment, businesses from all industries and sectors can ideate, iterate and innovate faster, safer and with a greater degree of accuracy than through traditional, manual methods.

Virtual twin technology has brought about life-saving programs like the Living Heart Project, which uses SIMULIA to enable surgeons to build models of individual patients’ hearts and understand the impacts of proposed surgeries and therapies on their unique anatomy. It helped automotive maker Xos decarbonize last-mile deliveries using electric trucks to enhance shipping and delivery capabilities without releasing excess emissions, leveraging various technologies on the 3DEXPERIENCE platform. Virtual twins have been used to decrease costly and wasteful prototyping of containers for consumer goods, prevent the transmission of respiratory illnesses in hospitals and design energy-efficient vessels for worldwide maritime shipping. From start-ups to enterprises, businesses of all sizes have impacted the world in innumerable ways using this kind of well-known technology.

Within virtual worlds, users can build and interact with virtual twins. For organizations seeking methods to iterate and innovate product offerings, the modeling and simulation software available in virtual twin experiences makes the solution an attractive one. For companies looking to lessen their environmental footprint, virtual twins offer a vehicle for scaling down emissions and realigning product components to reflect a path toward sustainability. For businesses aiming to inject agility into their supply chains, the tech provides solutions that can power quick, decisive shifts to maintain productivity and provisioning, no matter the market conditions. Across the board, this kind of virtual world technology impacts the world on a constant basis, improving lives unknowingly while contributing to the global economy and powering the worldwide workforce.

The audience

Virtual twins have historically been developed for and leveraged by industrial and business players. In the last decade, they’ve become a crucial component in the tech stacks of companies in the automotive, manufacturing, consumer goods, mining and engineering industries. Like some more advanced technologies, virtual twins require a particular skillset to be used. However, with the new announcement of the Virtual Twin as a Service, or VTaaS, model, this obstacle is removed. By providing a more white-glove service, Dassault Systèmes is able to offer even more customers a rich, virtual experience.

The technological building blocks

The backbone of Dassault Systèmes’ virtual twins and the experiences they power includes various kinds of complex software. They’re developed using proprietary technology built over several decades, including Business Information Modeling (BIM) and Product Lifecycle Management (PLM) solutions, hosted on the 3DEXPERIENCE platform. Those technologies are bolstered by 3D modeling, model-based systems engineering, computer-aided design and data and simulation solutions.

Increasingly, artificial intelligence is being added into the mix. But there’s a discrepancy between what casual consumers want, expect and accept from AI outputs and what the technology needs to be able to provide to enterprises for industrial use cases. For the former, the occasional hallucination might not inhibit their ability to derive great value from a tool, but for the latter, even a small misstep can have reverberating consequences.

“We believe in a hybrid approach that identifies the correct solution after a user’s intent has been understood and contextualized. This approach allows us to use the technology that’s best suited for a user’s needs, from sophisticated AI models like LLMs, to more specialized machine learning models or scientific solvers, or even the most basic algorithms. This approach provides a solution that’s relevant, exact, trusted and certified, adding a layer of trust to interactions between user and system,” said Diana Goenaga, strategy director for NETVIBES, Dassault Systèmes’ business intelligence brand.

From predictive maintenance in factory equipment to big data management, the introduction of AI into virtual twin technology is already making its mark on business innovation and transformation. But what’s important isn’t just the infusion of the technology into solutions, but a thoughtful approach that considers industrial and environmental best practices.

“At Dassault Systèmes, we want AI to serve industries in meaningful, responsible and scientific ways. Meaningful, because the benefits of AI for society must be bigger than the costs of AI, both financial and environmental. Responsible, because all that must be done with the proper guardrails to ensure it’s explainable, traceable and ethically compliant. For industries developing cars, medicine or infrastructure, the only way to consider AI usage is if it can be trusted to maintain product quality and safety. And scientific, because we already have a huge database of science-based models and algorithms that provide answers to questions on which LLMs aren’t always the most helpful,” Goenaga said.

By taking this kind of measured approach, the company’s offerings can balance the necessity for AI with the abundance of tried-and-true solutions that have been trusted for years.

The limitations

Virtual twins are based on available real-world data, so the validity and accuracy of that data are imperative; any errors will lead to problems down the road. There’s also no way to feed real-time data into virtual twins yet.

Because they’re more complex, they require certain technical skills to build and manage. That level of complexity represents a valuable investment in digital transformation for businesses looking to innovate at scale.

The confluence of real and virtual

Both Google’s and Dassault Systèmes’ virtual world technologies present the possibility for exploring spaces otherwise inaccessible.

Tools like Genie 3 can transport users to faraway places, both real and imagined. Virtual twin experiences powered by the 3DEXPERIENCE platform enable interactive access to soon-to-be real places – like proposed neighborhoods in the French city of Rennes. There, officials built a virtual twin of the blueprints for changes to various areas of the city and created a public exhibit where members of the community could “walk through” them. This imaginative approach was made possible through the technology that powers both Dassault Systèmes’ virtual twins and Genie 3’s virtual worlds.

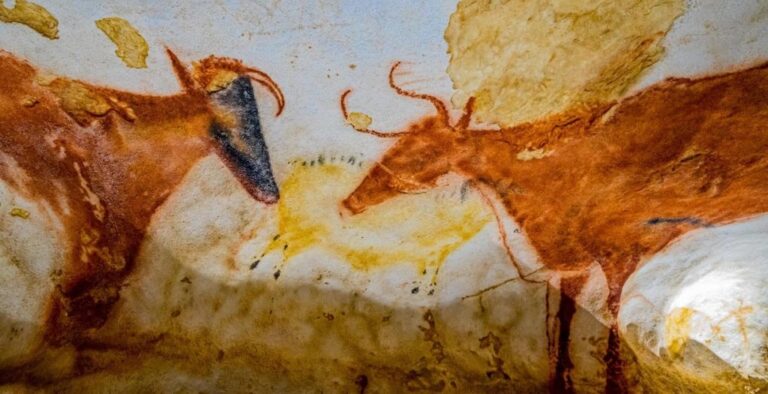

For exploring the natural wonders of the world, both companies’ virtual worlds offer unparalleled access not possible through other means. Take the Lascaux Cave, for example. These geological and anthropological wonders, located in France, contain paintings from more than 20,000 years ago. The cave was briefly open during the mid-20th century, but closed due to deterioration from human visitation. However, through a virtual experience developed with Dassault Systèmes, interested parties from all over the world can virtually visit it and explore its wonder. It’s experiences like these that inform the concept of “virtual worlds for real life” and provide endless opportunities for consumers and businesses alike to bring reality into digital conceptions that can, in turn, improve the real world.

The bottom line

As tools like Google’s Genie 3 become more prevalent and the concept of virtual worlds and twins becomes more widely known in the public sphere, access to this typically industrial technology is slowly being democratized. Virtual twin experiences have quietly been changing the world for years. Without realizing it, virtual worlds and the experimentation they enable have made everyday products more safe, more durable, more accessible. From cars and planes to supply chains and factory optimization, virtual twins have been improving the real world for more than a decade. But they’ve largely done so in a way that’s been hidden from the public view.

In reality, some of the world’s more innovative, successful and well-known enterprises have been building their products and processes with the help of virtual twin technology. This newfound accessibility might empower faster and more sustainable innovation to address global challenges, from reducing carbon footprints to optimizing supply chains. As more users tap into the capabilities of virtual twins, we can expect an acceleration in creativity and efficiency, fostering an environment where ideas can be rapidly tested and transformed into real-world solutions. The future of innovation lies in the hands of those who can leverage these digital capabilities, ultimately enriching our economy and improving lives on a global scale.