Once viewed as a technological tool used only in certain industries, virtual twins now play a pivotal role in the development of goods from simple to complex and from ubiquitous to rare.

The virtualization of real-world processes from conception to manufacturing to lifecycle monitoring has transformed countless industries. When we think of the challenges now facing the Life Sciences and Healthcare industries, it’s clear the potential for change from virtual twins is nearly limitless.

While still nascent, technological breakthroughs like virtual twins have already led to remarkable strides in this sector. We’ve seen new vaccines developed to combat the COVID-19 virus tested and produced in record time. Surgeons on different continents have collaborated in virtual operating rooms to safely separate conjoined twins connected by their brains. Hospitals virtually mapped their ventilation systems to reduce the spread of airborne disease. These advances represent the beginning of a renaissance in the healthcare field.

The introduction of such technologies has made clear that the way the industry has worked up until this point has been somewhat messy and disjointed, even without realizing it. Virtual twins enable endless possibilities for more accurate patient care, streamlined clinical trials, faster product development and deployment and an overall better approach to every aspect of healthcare.

Recently, Dassault Systèmes’ VP of Life Sciences and Healthcare, Claire Biot spoke on the DeviceTalks podcast about the 4 main pillars of virtual twins in healthcare: patient, plant, process and product. Following that interview, we sat down with her to discuss them further.

Patient

Today, we hear a lot about the concept of patient-centric care, but when we look at the implementation of technology in healthcare, the patient itself is missing. Surgeries, scans, x-rays: all of this can be viewed on a screen, but there’s typically no setting in which a doctor has full access to a patient’s entire physiology in a virtual way.

Consider a patient’s medical file: It might contain a sheath of papers detailing pre-existing conditions, prior treatments and other odds and ends. We’ve always thought of a medical history as a complete picture, but in reality, without being able to visualize all the bits and bobs together, it’s incomplete. By connecting these fragmented pieces of information, a virtual twin would allow practitioners to gain unique insights into a patient’s internal health, and then design the best treatment plan for them. These individual experiences could be combined with laboratory data to allow doctors to better understand diseases and explore new treatment options with more accurate outcome predictions. For patients, this means better care when they need it.

“Imagine a future where personalized healthcare is not a luxury, but the norm,” Biot said. “The virtual human twin will provide realistic experiences that take us a step closer to this reality, providing a virtual window into individual health. This technology could revolutionize innovation, diagnosis, treatment planning and disease prevention, enabling a new era of truly personalized medicine.”

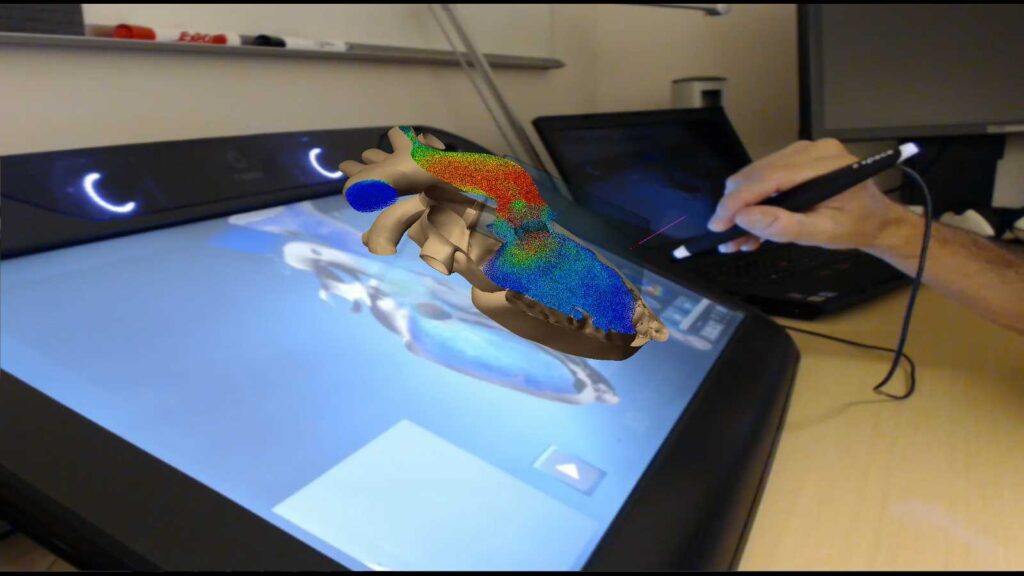

This version of providing patient care, far-fetched though it may sound, is already happening. For those suffering with cardiovascular disease, the Living Heart Project pioneered the development of virtual twins of the heart. Researchers are designing and testing treatments in the virtual world to optimize performance, clinicians are planning life-saving surgeries with the benefit of already having carried them out on a patient’s virtual twin and regulators are learning how to interpret clinical trials run purely on virtual patients.

Beyond simply being a tool to determine treatment plans and therapies for a patient’s physical health, virtual twins also have use cases applicable for mental health. VORTHEx – short for Virtual Oncology Radiotherapy Hartmann Experience – tackles just this. For patients diagnosed with cancer, the prospect of undergoing radiological treatments can be daunting and cause serious anxiety that leads some to avoid treatment. By providing patients with a virtual twin of the treatment room and process itself, VORTHEx aims to alleviate anxiety and stress, encouraging better patient outcomes across the board.

Product

Healthcare products – encompassing pharmaceutical drugs, medical devices and biological treatments – must pass stringent testing before they receive the approval to be brought to market, a costly and lengthy process. In addition to producing the safest product possible, companies also have speed in mind; think of the production of vaccines during the COVID-19 pandemic, and the rush to bring to them to market as soon as they were proven to be safe and effective. Virtual twins afford the opportunity to streamline the various processes associated with creating medical products. By enabling safety and efficacy testing in a simulated environment, they replace previously necessary physical prototyping, thus reducing cost, waste production and dependency on animals and humans for testing.

In the digital age, the healthcare market demands continuous improvements, smarter treatments and more sustainable solutions that work with a patient’s lifestyle. For manufacturers, this translates to a need for producing more innovative designs with greater complexity, yet all designed within the confines of a closely regulated industry.

Virtual twins represent the best way to manage these conflicting requirements, maximizing insights and automation while continuously managing manufacturing quality control software and regulatory demands.

“They can fast-track the innovations that companies need to ensure safe and effective production of medical products and therapies,” Biot said. “It’s the concept of failing faster or realizing earlier on in the process the necessary tweaks or changes needed to arrive at the optimal solution in a more efficient way.”

Customers have been able to use virtual twins to cut testing times from days to minutes, which can be the difference in the ability to meet the urgent needs, such as for vaccines which not only propel their business but impact society as well.

Process

Defining the right process for a medical product’s design and production is often the difference between success and failure. A great concept will fail if it is not properly developed, tested and produced.

“Virtualizing the development of new drugs or medical devices will bridge the gap between concept and reality,” Biot explained, adding that virtual twins allow companies to map out processes in a way that provides a layer of predictability and reliability.

Doing so provides insights for the best practices in creation, development and testing while ensuring safety, efficiency and quality. The best process will be unique for every product and can be defined at the outset and updated over time as more information is gleaned.

With the natural uncertainties in healthcare and related subfields, the ultimate goal, whether producing a product or prescribing a drug or therapy, is risk reduction. By simulating the behavior of a drug or device within a human body, virtual twins can help identify potential risks or side effects early in the development process, reducing potential harm to trial participants.

“By simulating the entire development process, from initial concept through to manufacturing, we can foresee challenges, optimize solutions, and enhance efficiency. We can bring medical innovation to the state-of-the-art that has been achieved in other industries,” Biot noted.

Throughout the development process, virtual twins can reduce the need for physical prototypes saving time, money and resources. Testing design variants virtually can shorten the development timeline, while ensuring the best candidate for a final product has been selected.

Just like development, production can also be explored virtually, so as to allow researchers to predict and adjust for potential issues before the actual production begins. For complex products, understanding problems at the get-go or early on can influence design to ensure cost containment and quality assurance.

As the final hurdle, regulatory concerns can be anticipated and built into the process. Virtual twins allow mapping of the unique features of solutions, new health risks they might pose and how best to prove medical claims. They can provide valuable details to produce accurate documentation of the development process, which can assist in meeting regulatory requirements and facilitating the approval process.

Plant

Creating a virtual twin of a manufacturing plant allows for optimal design of the production of drugs and devices, squeezing out the slow or weak spots that can reduce time to market or cause variability in quality. Once in production, the twin can be used to oversee operations and manage supply chain disruptions. When optimized, the twin can facilitate reliable replication for global markets and the flexibility to roll out updates as necessary.

“The virtual twin lets you walk through your manufacturing plant before it even exists,” said Biot. “By virtualizing the detailed design of a plant for the production of a new drug or medical device, you can identify and mitigate potential issues, optimize processes, and enhance productivity before the ground is broken. It’s more than collaborative innovation, it’s part of a total vision for a safer and more reliable future in healthcare.”

French pharmaceutical company Sanofi used a virtual twin of their production facility to increase capacity in their manufacturing plant by overcoming existing bottlenecks. This meant collecting data from the plant and constructing its virtual twin, complete with a functional model of the entire process. With this in hand, they adjusted parameters one by one to identify which combinations could safely increase the capacity of the washing area without using additional resources. Using a systems engineering approach, they were able to pinpoint changes which would deliver additional manufacturing volume.

In addition, a virtual twin helps manufacturers consider factors such as maintenance schedules, lifetime prediction and replacement costs including unexpected disruptions that may affect production processes. Operating conditions such as humidity or internal air-flow patterns can be included to know what to expect and be prepared, or even better make the design changes to avoid them altogether.

Our belief is that the virtual world extends and improves the real world.In the virtual world, we can simulate and evaluate impacts before producing the product itself. Virtual worlds help people imagine differently. Taking our four-pronged approach to virtual twins ensures that in each instance, the patient need is well understood, the product delivers value to the patient, the process delivers the product with the right quality and cost and the plant is designed to accommodate the process efficiently and sustainably.

Imagine as a patient, physician or professional, being able to visualize, understand, test and predict what cannot be seen, from the way a drug affects a disease to the way a therapy is developed to the way a surgery is performed. These insights can transform the entire industry for the better.

To learn more about our progress on this topic, join us in Boston, June 7-8 for the 9th Annual Virtual Human Twin Experience Symposium. The event brings leaders from a variety of sectors within the healthcare industry to share the latest advances in the simulation of the human body.

Listen to the full episode of the DeviceTalks podcast to hear more from Biot on this topic.