Accelerating the XAMR journey with a fully connected, simulation-driven digital ecosystem

Global energy demand is expected to nearly double by 2050, and the need for reliable, low-carbon solutions has never been more urgent. In this context, NAAREA, a French energy-tech start-up, is taking a bold step toward a cleaner and more circular future. The company is developing the extra small Advanced Modular Reactor, a fourth-generation, fast-neutron, molten-salt micro-reactor designed to produce heat and electricity using long-life nuclear waste as fuel.

To achieve this ambition, NAAREA uses the 3DEXPERIENCE platform on the cloud to accelerate design, ensure full traceability of engineering data, and support the entire reactor lifecycle with a single, unified digital environment.

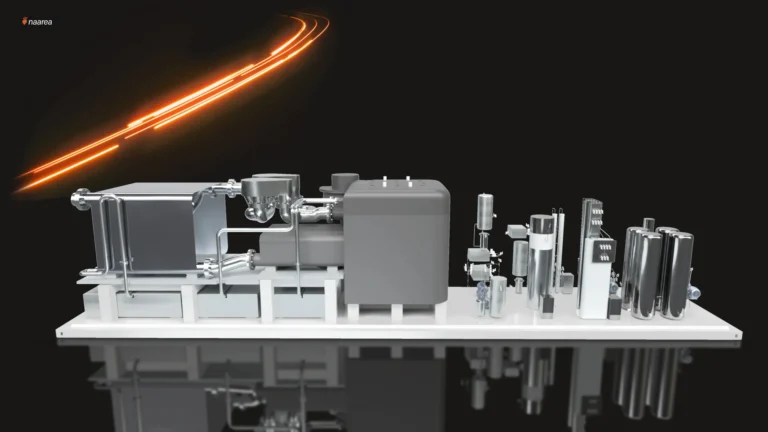

A virtual twin built in only 18 months

Developing a novel reactor architecture requires speed, precision and seamless collaboration across multiple engineering disciplines. NAAREA built the first version of its reactor’s virtual twin in only 18 months, an impressive achievement for such a complex system. Teams now work within one shared environment for 3D modelling, simulation and lifecycle data management, supported by continuous configuration and requirement traceability.

This digital foundation is the company’s single point of entry for all knowledge and design work, connecting mechanical, thermal, hydraulic, neutronics and electrical engineering through a common data model. The result is a collaborative workspace where decisions are made with the full context of geometry, simulation results, technical requirements and regulatory constraints.

Ensuring safety, compliance and credibility from day one

In the nuclear sector, confidence is built on transparency and demonstrable control. The virtual twin plays a central role in NAAREA’s approach to safety and certification. Every design change, simulation result and validation activity is captured within the platform, creating a complete and auditable digital thread across the entire lifecycle.

As CEO Jean-Luc Alexandre notes, the virtual twin is essential not only for design and development, but also for safety and security demonstrations, manufacturing, deployment, operation and end-of-life management. This continuity supports the company’s objective to become a full-service energy provider capable of delivering, operating and maintaining its fleet of reactors.

Circular, decentralised, low-carbon energy

The XAMR is designed to address several critical challenges simultaneously. It produces carbon-free energy close to demand, operates without reliance on a large body of water for cooling, delivers both heat and electricity efficiently and uses long-life nuclear waste as fuel.

Its small footprint, roughly the size of a bus, opens the door to decentralised deployment scenarios. Industrial sites, remote regions or developing countries with limited grid access become viable locations for safe, clean and reliable power generation. This shift toward compact and circular nuclear energy aligns with broader efforts to build resilient and sustainable energy systems.

One platform powering the full lifecycle

With a cloud-based implementation of the 3DEXPERIENCE platform, NAAREA benefits from rapid deployment and minimal IT overhead. Engineers access the platform from anywhere, collaborate in real time and maintain full control of change management and configuration management.

The platform integrates ENOVIA for lifecycle governance and SIMULIA for multi-physics simulation, enabling the company to evaluate subsystem maturity, test design hypotheses, and validate safety cases early in development. It also supports advanced visualisation through 3DEXCITE to communicate the reactor’s design to partners, regulators and customers, even before any physical prototype exists.

This digital continuity strengthens decision-making, reduces development risk and accelerates pathways to licensing, industrialisation and deployment.

NAAREA’s goal is clear. The company aims to scale toward industrial deployment and evolve into a full-service clean-energy provider by 2030. The virtual twin will remain central to this strategy, providing the digital backbone required to design, certify, manufacture, operate and eventually decommission a new generation of micro-reactors.

For the broader nuclear community, the work of NAAREA highlights how an integrated, model-based approach can bring innovation to market faster, all while maintaining the highest levels of safety and regulatory readiness. As countries worldwide seek secure, low-carbon energy solutions, the combination of fourth-generation reactor technology and digital continuity offers a compelling path forward.