Companies know intuitively a proactive approach helps avoid supply chain challenges from stacking up. Consumer goods manufacturers look to modernize manufacturing to improve the supply chain and they start with improving logistics. Today, consumer goods organizations—from furniture makers to sporting goods and luxury footwear brands—seem focused on having better control over logistics to reduce supply chain risk. Rising costs, sustainability goals, and consumer demand for personalization and product variety mean traditional logistics methods may not cut it anymore. But here’s the good news: optimizing the supply chain for consumer goods manufacturers starts with adopting a digital, integrated logistics strategy. This blog defines how to modernize manufacturing to improve the supply chain.

Why Are Supply Chains So Complicated These Days?

It’s almost universal, across consumer goods manufacturing companies, whether manufacturing furniture, sporting goods, or luxury footwear, major headaches arise from the complexity involved in supply chain management. With many culprits to blame, here are three:

SKU Overload: Juggling too many product variations? The explosion of SKUs makes inventory management and demand forecasting a serious challenge.

Rising Operational Costs: Whether higher material costs, labor expenses, or time consumer regulations, companies feel the pinch. Rising costs and extra rules chip away at margins.

Sustainability Demands: Savvy supply chain management helps sustainability goals. By improving traceability, reducing waste and emissions and enabling responsible sourcing –manufacturers can reduce their environmental footprint and meet tightening regulations.

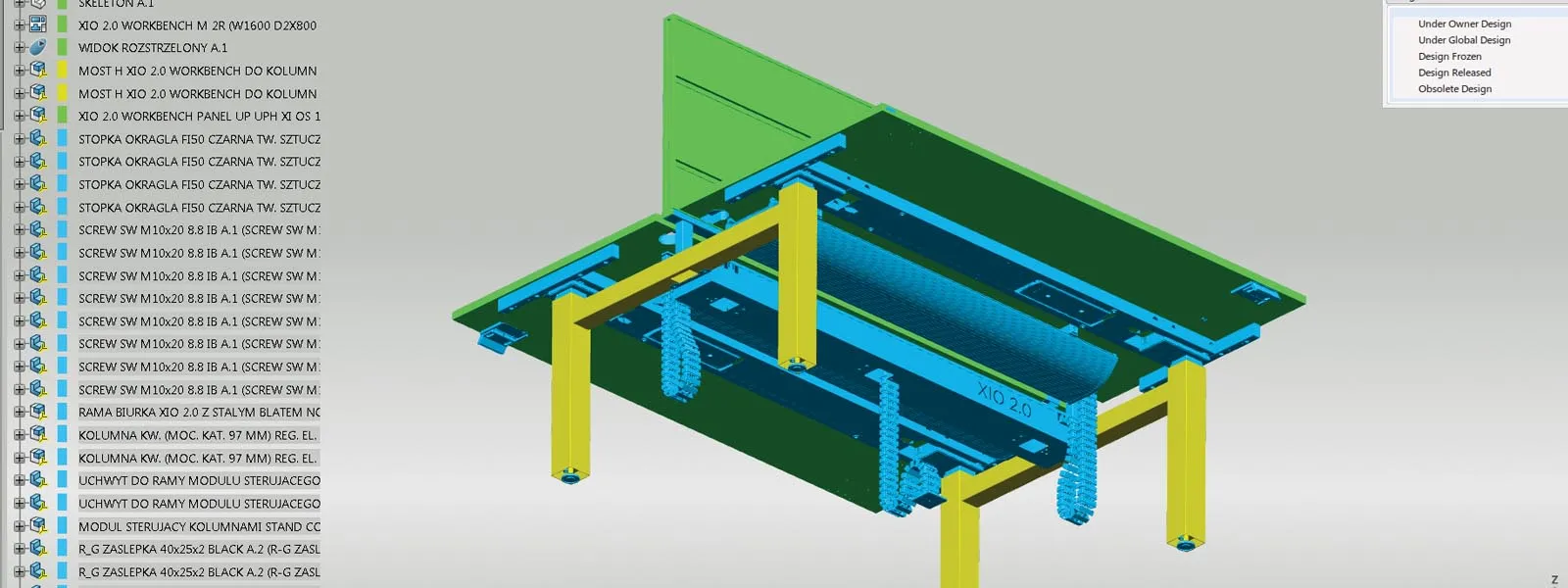

Software technology that uses virtual twins help simplify supply chain complexity.

What’s a Virtual Twin and How Does it Make Supply Chain Logistics Easier?

To meet the challenges of disruptions to the supply chain and factory operations companies seek more efficient processes and operations. Using a unified platform that uses virtual twins offers many solutions for consumer goods companies. A digital model (virtual twin) represents the real-world components and behavior of a product. This virtual twin allows engineers to perform simulations very early and at all phases of a product’s life. A virtual twin integrates real-time data to simulate behavior with precision. This enables efficient process control, product monitoring, and continuous improvement from design to end of life.

Using a virtual twin (of a physical scenario) to run “what if” scenarios until you find the best answer to address supply chain and market demand changes. With early information, you can avoid major disruptions. And, it seems logical that integration across functions also improves automation and computer control. The use of data and machine operations to optimize the entire manufacturing process.

-Consumer goods companies can connect disciplines across departments on the 3DEXPERIENCE platform to:

-Reduce development and response time to changes by up to 30% and drastically reduce manual data processing;

-Improve manufacturing flexibility to accelerate time to delivery and adapt to consumer demand; and

-Increase production efficiency by optimizing inventory and matching on time, in full up to 100%.

Industry leaders reap many benefits applying virtual twins through a common platform accessible to teams and suppliers in real-time. Companies can immediately improve collaboration, optimize processes, and anticipate and avoid or quickly correct production and supply issues.

Solve Supply Chain Challenges in Furniture, Sporting Goods, and Footwear; a Deeper Look

Interested in a more detailed break down with case studies by industry segments?

Furniture Manufacturers: A myriad of supply chain disruptions frequently negatively impact operations (material shortages, transportation issues, and late engineering changes). Companies like furniture maker, Nowy Styl looks at every option to optimize operations and reduce these risks. Read the Nowy Styl story to learn how the company improved collaboration with its supply chain. A leader from the Poland-based office furniture shares how they standardize processes to launch new products and customer solutions faster.

Sporting Goods Companies: Predicting demand, managing material costs, and timing seasonal merchandise launches require strong logistics. The ability to collaborate with suppliers supports increased component reliability, lower material costs, and early identification of issues. Early versus late action usually determines success or failure. The company uses the 3DEXPERIENCE platform and solutions to manage at least 50 R&D organizations in developing high strength materials for its ebikes. Learn the advantages ebike manufacturer, I-FEVS gained.

Luxury Footwear and Athletic Footwear: Footwear brands use fashion, fit, and quality to differentiate their products. Now they also use sustainability and a digital infrastructure to differentiate their operations. Global footwear brand ASICS envisions a future that includes manufacturing on-demand with a low environmental impact. Watch an interview with ASICS leader Kenichi Harano, Executive Officer and Senior General Manager. The discussion includes how consumer brands can better manage material costs and improve digital logistics to meet consumer and environmental expectations.

Strategic Moves for Manufacturers to Make Now

Wondering where to start to modernize manufacturing to improve the supply chain? Consider these key areas:

• Invest in Integrated Digital Solutions: Streamline logistics, inventory, and sustainable practices in one digital platform. Use a united environment to simplifies your operations and boost visibility.

• Strengthen Supplier Relationships: Improve supplier connections. With greater transparency and collaboration companies can reduce disruptions and recover more quickly.

• Analyze Sources: Use what if scenarios to understand the impact of nearshoring or finding alternative suppliers. Have options available to reduce risks from unexpected disruptions.

• Prioritize Sustainable Practices: From reducing transportation costs of parts and materials, to choosing materials with a lower environmental footprint, sustainable practices can be integrated through the full product lifecycle. Consumers and regulators expect it.

• Leverage Virtual twin technology: Use virtual twins on the 3DEXPERIENCE platform to collect, visualize, and analyze product data in real time. Regulations evolve quickly. Using traceability can help your company stay compliant—and ahead of your competitors.

Optimizing Logistics: The Secret Weapon for Consumer Goods Manufacturers

Ditch disconnected, manual planning tools that slow down your supply chain and inflate costs. Logistics planning for consumer manufacturers requires eliminate these types of roadblocks. How? Streamline on a single digital platform by connecting production planning, scheduling, and execution. Read more about advanced planning and scheduling solutions. Learn why companies move from static spreadsheets and siloed systems to plant-centric, real-time collaboration across business functions.

Overall, automating end-to-end operations reduces complexity and increases agility across production.

Expected Results from Modernized Manufacturing with Advanced Planning and Scheduling

The results speak for themselves. Modernize manufacturing to improve the supply chain with advanced planning and scheduling. Replacing manual spreadsheets offers the possibility of these benefits:

-reducing planning time by up to 80%;

–increasing production throughput by up to 18%; and

lowering quality claims by as much as 90%.

Thriving in today’s market isn’t luck–it’s logistics. Strategic planning provides the secret weapon that turns your supply chain into a competitive advantage. Join the consumer goods companies that embrace a software-driven, integrated platform for engineering and logistics. How will your company meet logistics challenges head-on? You can start by modernizing your manufacturing to improve the supply chain with the 3DEXPERIENCE platform and industry solution experiences for consumer goods companies. Enhance your supply chain efficiency. Position your company to manage costs. Meet and exceed consumer expectations. Deliver on sustainability promises.