The following article is based on the plenary presentation, Unified Modeling & Simulation for Sustainable Product Development, presented at the 2022 Global 3DEXPERIENCE Modeling & Simulation Conference. The Dassault SystèmesMODSIM team gave examples of three different industries to demonstrate how the tight coupling between modeling and simulation helps companies meet their sustainability goals.

Introduction

The word “unified” has its roots in the Late Latin word “unificare” meaning to make into a whole. Unified can mean many things: bringing people together, working toward a common goal, or organizational alignment. Modeling and simulation, once separate entities, have transformed into one unified design approach, MODSIM.

Sustainability is one of the strongest business drivers companies are facing today, with far-reaching environmental implications. In this post, we will show how unified modeling and simulation can support sustainability goals by first looking at the layers of MODSIM and then exploring three different industries where MODSIM is transforming product development.

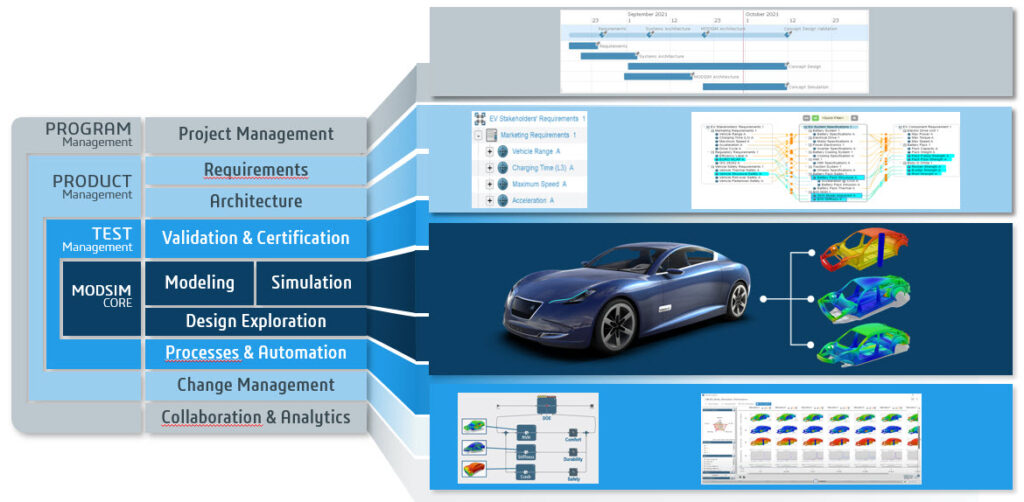

MODSIM as an Onion

Like peeling back an onion, there are layers of MODSIM, each with a specific use case and their interactivity with each other. The core of MODSIM is where we find the unified model and simulations, the associativity between the two, and the multiphysics. Next, we have the test management layer, where we are testing the product and have very detailed validation plans with test specifications, the results, and the reported outcomes. Around the test management layer, we have the product management layer where we find functional requirements and specifications. The next layer is the architecture layer where we have systems models and configuration data working together.

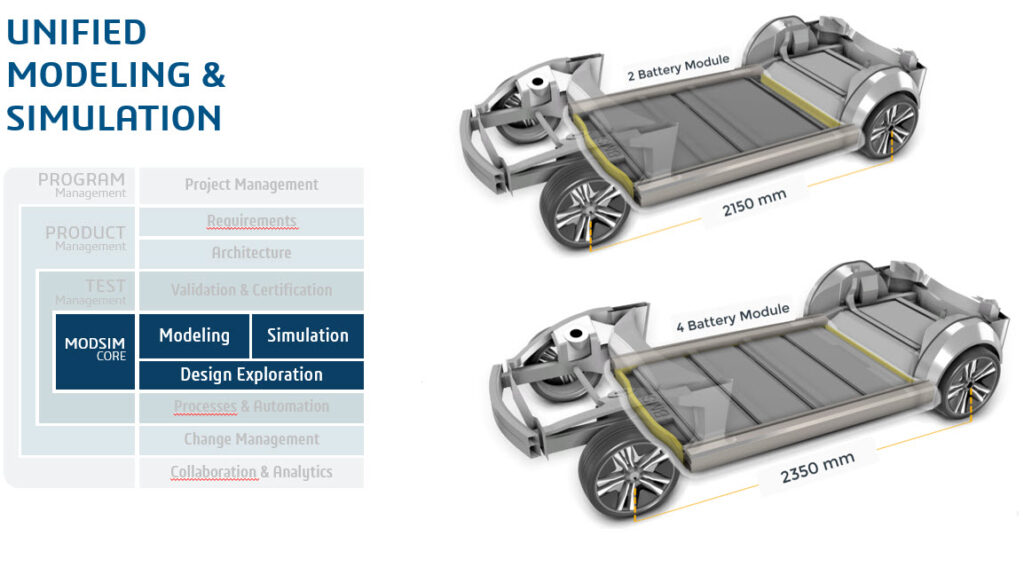

First, let’s look at the core of MODSIM by exploring one particular example, a floor panel of an electric vehicle. Here we have a fully parameterized floor panel that we are using to set up an analysis. We can mesh the floor panel and set up all the information required for the simulation, in this case, a side pole impact. For this analysis, we want to verify the stiffness of the floor panel to make sure that the batteries are not impacted in a crash. Once the analysis is created, we can run through many change scenarios. We want to optimize the floor panel to be stiff enough to carry the load of the battery, but at the same time, it has to be soft enough to absorb all the energy of the impact.

However, what if you have already developed your first car and you don’t want to start from scratch when beginning a new vehicle program? With MODSIM, you can reuse everything from a previous analysis. For example, you can go from a car that previously had two battery modules to one with four battery modules and you can extend the wheelbase as well.

Now, let’s dive deeper to see how the different layers of MODSIM work in specific industries, with three different examples: electric drive, wind turbines, and lightweight packaging.

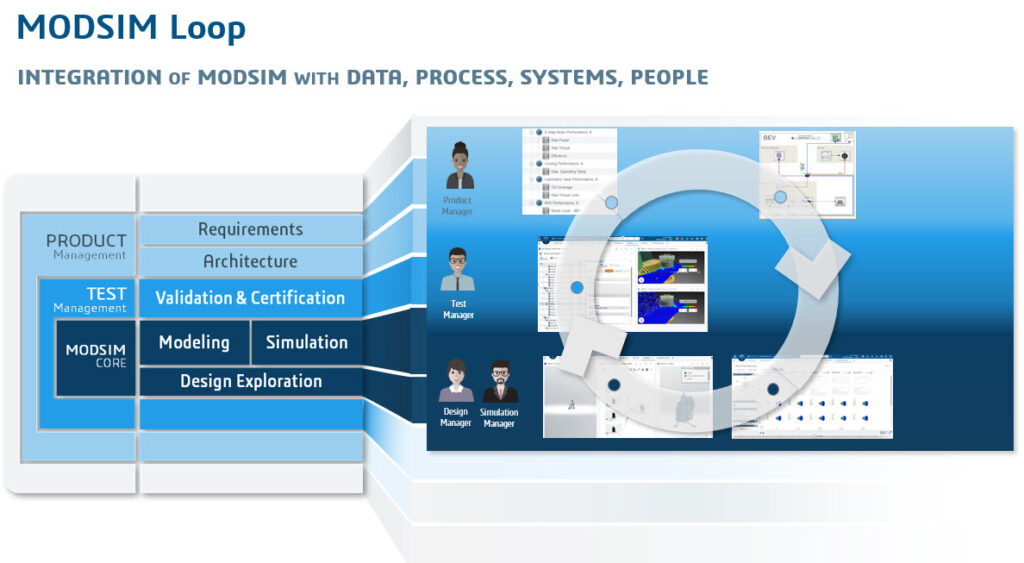

Electric drive

- The scenario: The automotive industry is leading the way in sustainability efforts with the development of electric vehicles. In this example, we have a performance e-motor unit, and you can see this is a fully parametric model, very detailed, but fully parametric. We started with vehicle requirements at a high level. We cascaded those down to system requirements for the electric drive unit. We then cascaded those down further to the system model parameters for the e-drive unit, and then we updated our model, which updated our simulation, and that updated our test outcome, and then that test outcome goes back to the product manager who will update the vehicle requirements and we will go again.

- The value: Better outcomes with a full MODSIM loop. With MODSIM, users have access to integrated data, processes, systems, and people, which leads to an accelerated product development cycle. When it comes to sustainability, looking at each system individually, optimizing individually, and then bringing them all together at the end only sees efficiency savings in the electric drive train of 15-25% versus 40% when the system is optimized as a whole integrated unit on the 3DEXPERIENCE platform.

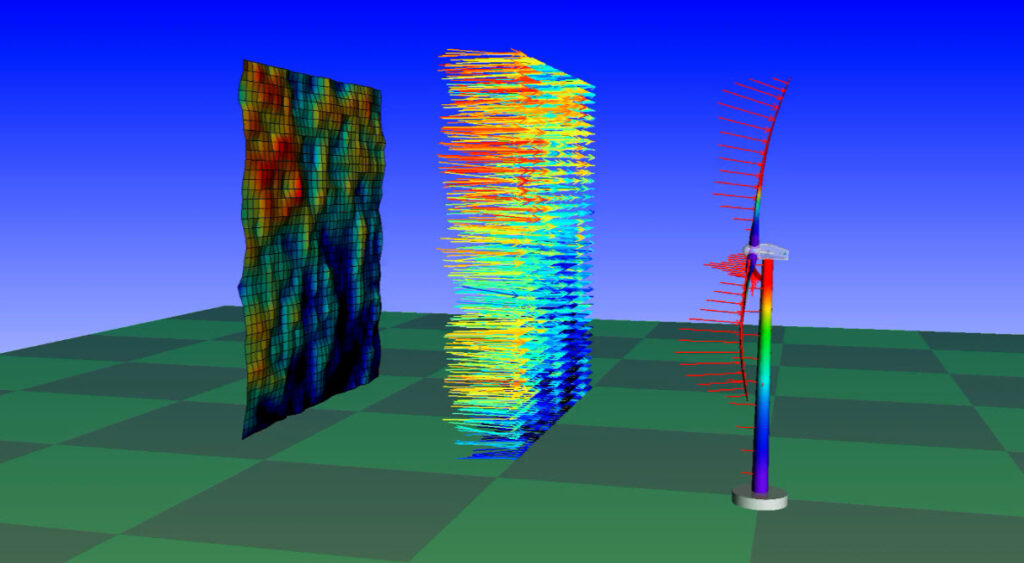

Wind turbines

- The scenario: Let’s look at an example of how MODSIM is used for generative design with wind turbines. The first thing we have to understand is the size of wind turbines. They are massive and they are continuing to grow in size. We’re already seeing turbines with rotor diameters of over 250 meters, and that’s predicted to grow. With wind turbines, it’s important to know that we can’t take one and put it into a wind tunnel to test a hundred-year wind gust. Wind turbines are very complex bodies, with a lot of curves and smooth-flowing shapes. If we look inside that blade, we see that it’s made up of many different materials. We have fiberglass materials, we have a foam core, and we even have boss wood, that’s helping to hold that aerodynamic shape along those profiles. There’s a lot to be considered when you design wind turbines.

- The value: MODSIM is helping us accelerate the energy transition away from fossil fuels to renewable energy. Simulation on the 3DEXPERIENCE platform is driving the rapid implementation of new wind turbine designs by streamlining product development cycles. This can only be done with simulation since physical testing of wind turbines is complex, expensive, and inefficient.

Lightweight packaging

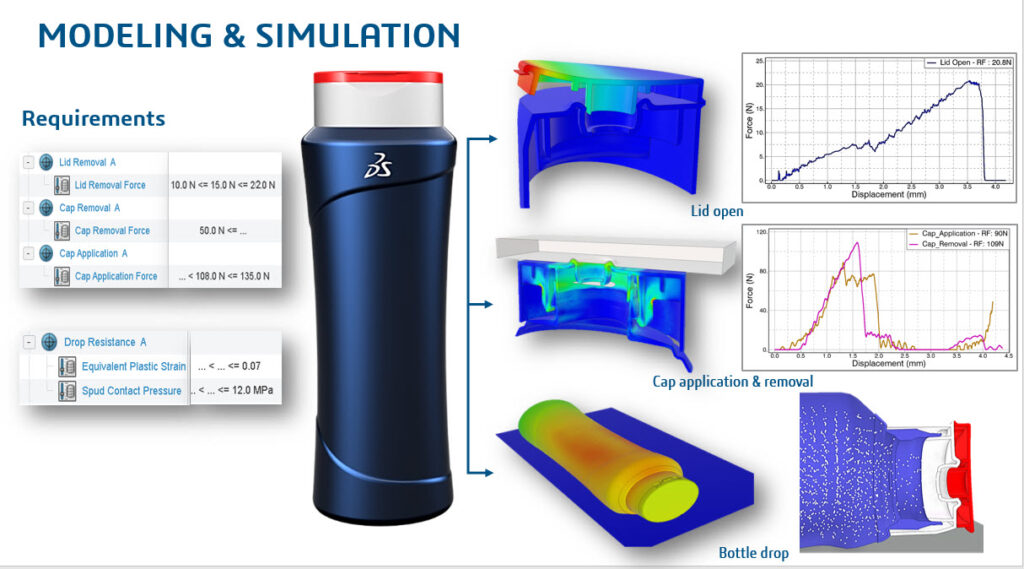

- The scenario: Consumer packaged goods companies have steep sustainability targets. They want to reduce the weight of bottles while also reducing the use of plastics. Bottle design starts with the evaluation of the material properties. Let’s look at a 350 ml bottle. A bottle, unlike a car, or an airplane, is just an assembly of three components. You have the bottle, you have the cap, and you have the lid. In this case, we have chosen three simulations, and you see on the left-hand side the requirements for these simulations. We have the lid removal workflow, the cap application and removal, and finally the bottle drop. We can see all of this modeled in the 3DEXPERIENCE platform.

- The value: MODSIM enables changes in roles where simulation specialists become methods developers, where design engineers not just create their designs but also start validating the product, and where more users participate in the product development process. This helps companies start meeting their sustainability targets at a much faster pace, reducing the weight of the bottle by 20% and achieving the required sustainability targets, and of course, reducing the time of product development. In this particular case, the development cycle was culled from 10 months down to three weeks.

Summary

Sustainability is key to preserving our planet and protecting our natural resources for future generations. Many companies now commit to sustainability with a holistic business approach to support their goals. The product development transformation needed to support sustainability covers three important areas where simulation and modeling play a key role: alignment to regulations, faster time to market, and the workforce of the future. MODSIM gives users the power to reach sustainability goals with a lighter product, a more optimized design, and the most appropriate material, all in one space on the 3DEXPERIENCE platform.

To learn more about MODSIM, the 3DEXPERIENCE platform, and to hear this presentation in its entirety, please visit the MODSIM community.

SIMULIA offers an advanced simulation product portfolio, including Abaqus, Isight, fe-safe, Tosca, Simpoe-Mold, SIMPACK, CST Studio Suite, XFlow, PowerFLOW, and more. The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.