What is Laminar Separation?

When calculating the physics of fluids, there are two basic types of flow – laminar flow, and turbulent flow. Laminar flow is smooth and avoids mixing between “sheets” of fluid, while turbulent flow is chaotic. Modeling one type of flow on its own is one thing, but what happens at the transitions between regions of laminar and turbulent flow?

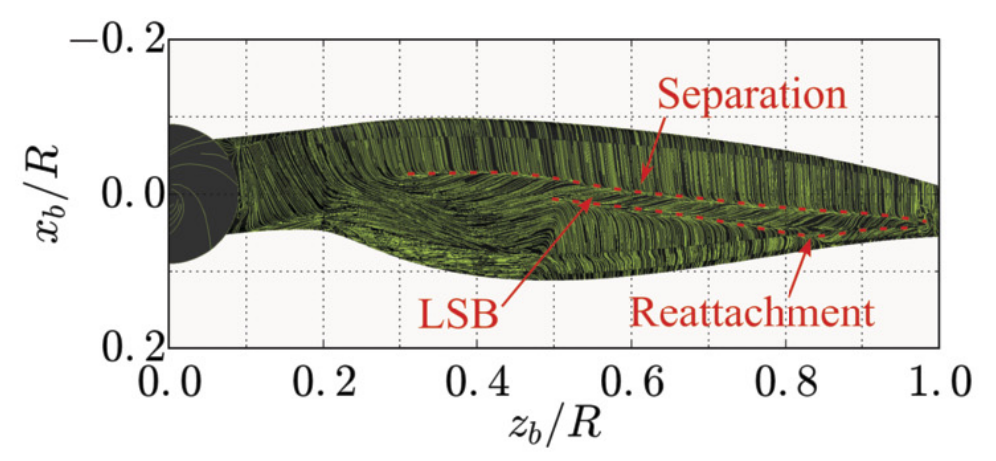

One common place where this transition is critical is around relatively slow-moving propeller or fan blades, such as found on electric vertical takeoff and landing (eVTOL) craft and wind turbines. The speed and scale of these mean that they have a relatively low chord Reynolds number, below one milion. This can lead to a complicated boundary layer behavior – laminar flow on the leading edge separates, travels over the blade in a laminar separation bubble, and then reattaches at the trailing edge.

This doesn’t only affect the aerodynamics of a propeller – the interface where the airflow over both sides of the blades meet and reattach is also one the main sources of blade noise. Accurate noise simulation also requires modeling the laminar separation and reattachment.

Applications of Laminar Separation Simulation

eVTOL craft are of interest for developing new solutions for urban air mobility. Quadcopter-type drones are already widely used, but larger vehicles have potential for uses ranging from logistics to aerial taxis. For these to be successful, they need to be able to operate safely in built-up environments, while also being quiet enough to be tolerated by local residents.

eVTOL craft propellers typically rotate relatively slowly (at least compared to more conventional aircraft). The Reynolds number in the operating regime of these propeller blades is low enough that laminar separation bubbles can form. Understanding effects such as thrust, drag and noise requires modeling these accurately.

Wind turbines are another significant application where laminar separation occurs. Wind turbine blades rotate very slowly – typically just a few RPM – which means they have a relatively low Reynolds number. Laminar separation from wind turbines can give rise to considerable noise. Wind turbine noise has negative impact on local communities and is one of the main causes of objections to new wind farm projects, and so understanding laminar flow separation and reattachment is crucial to a successful design.

Laminar Flow Simulation and the Turbulent Model Extension

PowerFLOW has long been an industry standard for aerodynamic and aeroacoustic simulation thanks to features such as for automatic grid generation, automation & scalability which speed up simulation set-up, and a powerful particle-based solver with Very Large Eddy Simulation (VLES) turbulence models. To simulate transition effects, users formerly had to manually add trip elements to the model that replicate the separation effect. However, a new technology in SIMULIA PowerFLOW offers a fast and accurate method for automatically simulating laminar separation: the turbulence model extension to PowerFLOW VLES.

PowerFLOW uses the Lattice Boltzmann method to calculate fluid flows, specifically the VLES method, which is well suited to turbulent flows. The new version extends the Lattice Boltzmann VLES method to cover the laminar-to-turbulent transition so these can also be captured in the same simulation. This can simulate both airflow and noise from the laminar-turbulent transition regime.

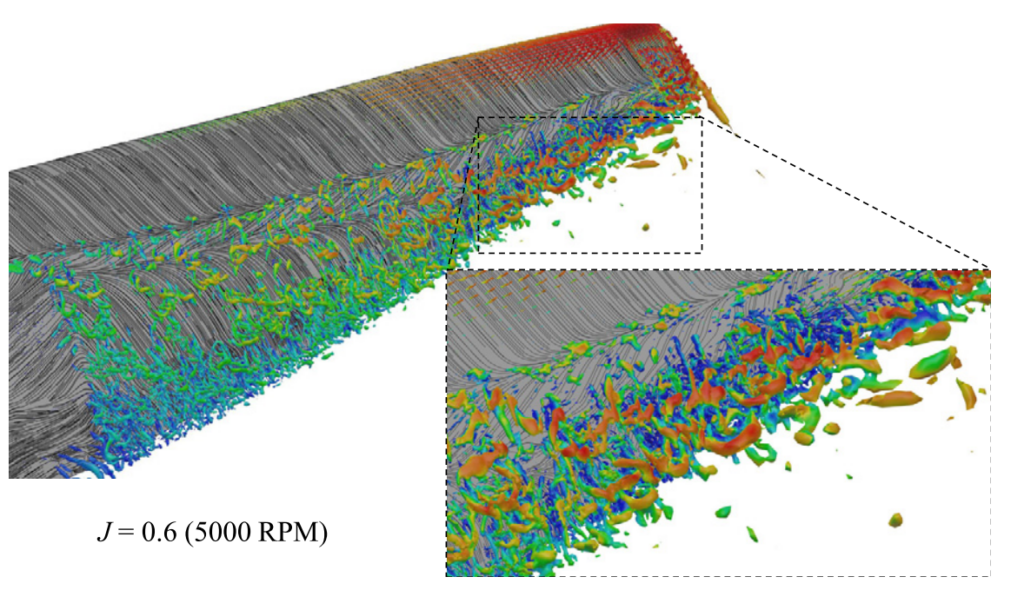

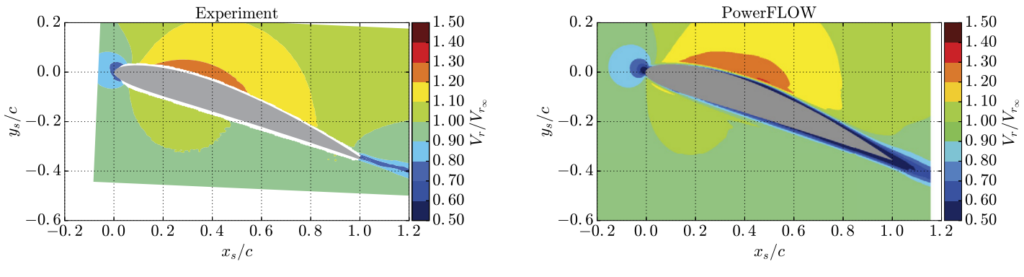

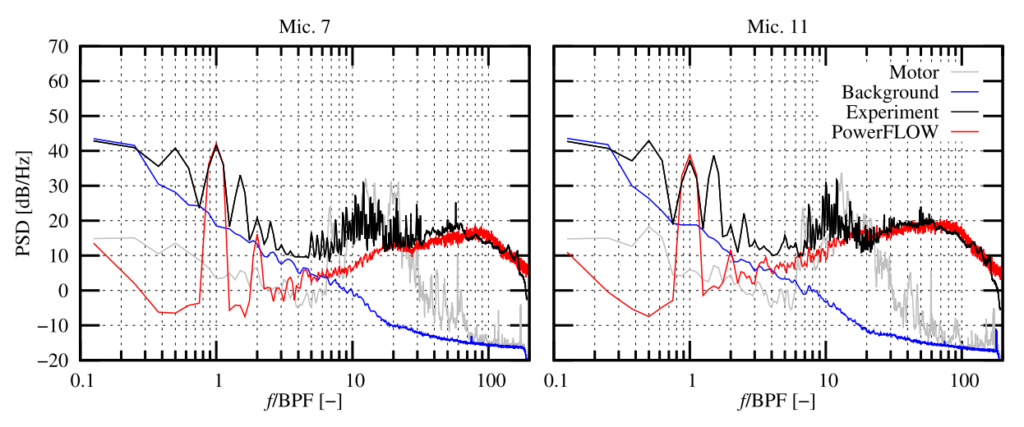

The accuracy of the turbulent model extension has been verified experimentally. A propeller was constructed and rotated so that the chord-based Reynolds number was on the order of 7×104. At this speed, a significant laminar separation bubble was observed. As shown in Figures 2 and 3, PowerFLOW provides excellent agreement to measured velocity and noise around the blade. VLES with the transition model extension was more accurate than using a geometric “trip” to force the separation. For more information about this, you can find the full published results in “Lattice-Boltzmann calculations of rotor aeroacoustics in transitional boundary layer regime” in Aerospace Science and Technology, Volume 130, November 2022, 107953.

Conclusion

When the Reynolds number is relatively low, laminar flow effects can be important. This gives rise to laminar separation bubbles and increased noise. Common examples of this phenomenon include the flow around eVTOL rotors and wind turbine blades. Simulating this transition has traditionally been challenging.

The PowerFLOW VLES (Very Large Eddy Simulation) turbulence model extension resolves the transition between laminar and turbulent flow efficiently and accurately. Aerodynamics and aeroacoustics simulations can both take advantage of the turbulence model extension to speed up simulation set-up or simulate scenarios that couldn’t previously be modeled.

Interested in the latest in simulation? Looking for advice and best practices? Want to discuss simulation with fellow users and Dassault Systèmes experts? The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.