Improvements in internal combustion engines have long been the main source of innovation in the automotive industry. Today, the electrification of this industry requires a transition of innovative activities to battery cells. While government commitments on air quality are maturing, consumers demand, as well as electric vehicle (EV) sales, is dramatically increasing and requires higher productivity from manufacturers to absorb the overall 40% increase in costs*.

Battery research and development for fast charging and longer battery life will be key for future success and adoption of EVs. Businesses that achieve scientific and technological breakthroughs in this field will be the leaders of this new industrial age. However, battery development faces several challenges: they are expensive, massive, require rare materials and are hardly reusable or recyclable in the long term.

The Innovation Chain

Traditional research, design and engineering tools will not be suitable to reach the required pace of innovation. Advances in materials, architecture, module integration, security and performance must all converge to meet this new challenge. The required expertise does not reside in a single team of design or engineering, but is spread over the entire automotive industry. To get revolutionary performance, companies and their partners need to master all the stages of materials science, cell design, integration into EVs and manufacturing. It is essential to study battery engineering across the coupled disciplines of electrochemistry, heat transfer, diffusion, convection and structural integrity. From an organizational point of view, data must be continuously accessible across development teams. A collaborative approach, without the information silos of the past, is an essential prerequisite.

Advanced technologies for unified design, modeling and simulation (MODSIM) allow collaboration between EV designers and battery engineers throughout the development cycle. Thanks to predictive virtual tests, teams can better evaluate materials and design alternatives to obtain optimal solutions faster. For example, modeling and predicting the swelling of the batteries with high accuracy requires a strong synergy between scientific and technological disciplines and virtual tools. The multidisciplinary nature of battery development pushes MODSIM to a new level, as the EV battery and chassis are fully integrated. This was not the case with internal combustion engines.

Connecting the Development Stages with a Digital Thread

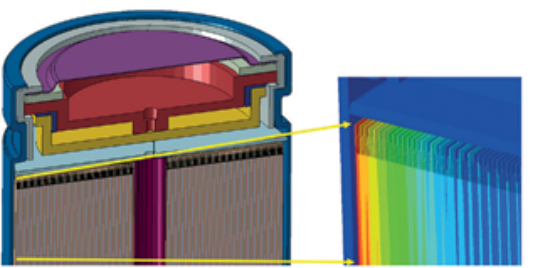

The requirements for improvement in security, density energy and battery life involve exploring new materials and electrolyte formulations. Predictive virtual tests must address physical modeling issues and chemistry of materials at multiple scales. Thanks to multiphysics/multiscale simulation technology for 3D battery cell design, analysis and improved mechanical coupled behavior, thermal, electrochemical ensure the safety and optimize performance.

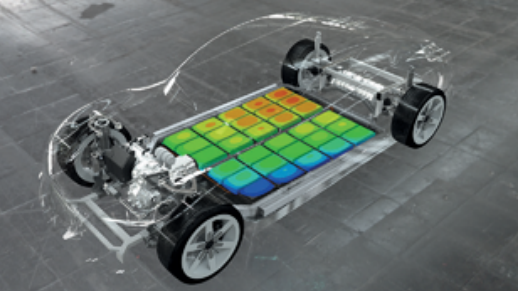

The development progression continues with the design of the battery module and the entire block configuration, where design and engineering teams collaborate on structural integrity, safety and thermal management with the objective of certifying to the strictest current standards. Multiphysics simulation is used to analyze the module and block thermoelectric performance in the battery cell itself. The simulation structure helps validate the battery module under crushing, falling, impact and penetration. Design alternatives of the modules and their cooling can be analyzed virtually over load cycles arbitrary and discharge, under various conditions, to achieve the required thermal characteristics. As traditional physical tests can take several months, virtual testing with MODSIM can significantly reduce the time to make reliable performance decisions.

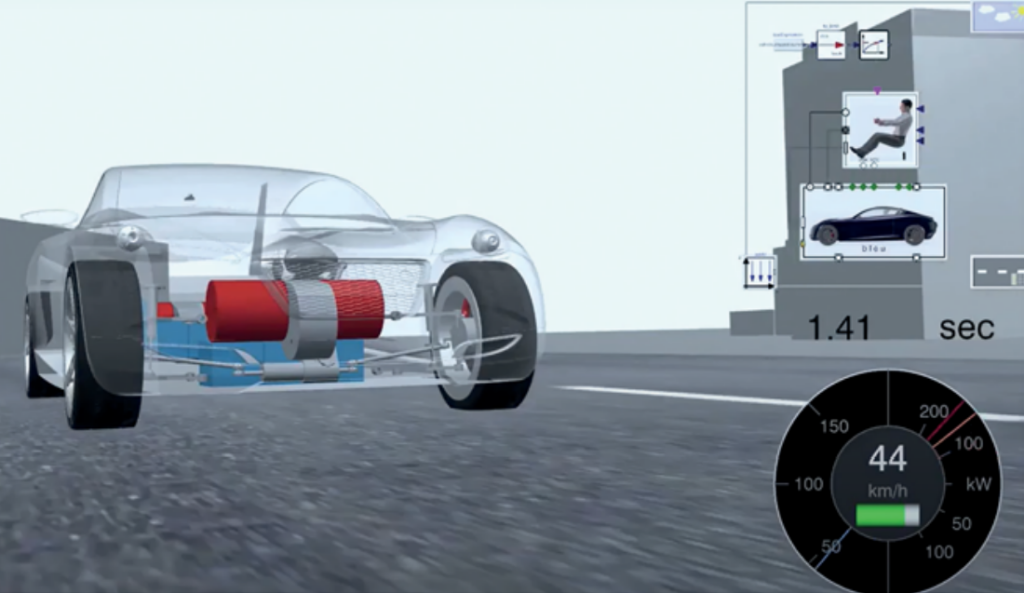

At the same time, designers and engineers can collaborate on integration from the battery pack to the virtual twin of the complete vehicle and the management system (BMS). With the traditional development tools and methods, performance gains from previous steps can be stifled by the limitations of the BMS design. A collaborative environment helps avoid unforeseen problems and provides performance information of the system in the context of the complete vehicle. The real-time dynamic full vehicle simulations can be performed to assess the performance of VE in a range of operating conditions of the vehicle.

Reasons to Believe

It is unprecedented for a major industry to have such a significant impact and simultaneously be in a phase of accelerated invention and innovation. State-of-the-art design, modeling and simulation software is essential to support the complex nature multiphysics and multiscale of battery cells.

A revolution in the automotive industry requires the democratization of science, design and simulation to succeed in its biggest challenge in generations. Virtual design, testing and validation accelerate innovation, processing technology digital must offer collaboration capabilities, continuous analysis and secure management of data, 3D design and precise physical simulation to have real predictive value. The unified capabilities of design, modeling and simulation are at the heart of Dassault Systèmes’ 3DEXPERIENCE platform, including contribution to digital transformation that is not just a set of independent tools, but a unified, cloud-enabled, collaborative platform giving teams the opportunity to work together throughout the life cycle of their products. MODSIM on the 3DEXPERIENCE platform is the optimal solution for bringing new generation batteries to market, to meet the demands of consumers, governments and our society’s future.

*Stellantis CEO Carlos Tavares interviewed by Breana Noble of The Detroit News, July 21, 2021.

SIMULIA offers an advanced simulation product portfolio, including Abaqus, Isight, fe-safe, Tosca, Simpoe-Mold, SIMPACK, CST Studio Suite, XFlow, PowerFLOW and more. The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.