The Commercial Case for Quieter Wind Energy

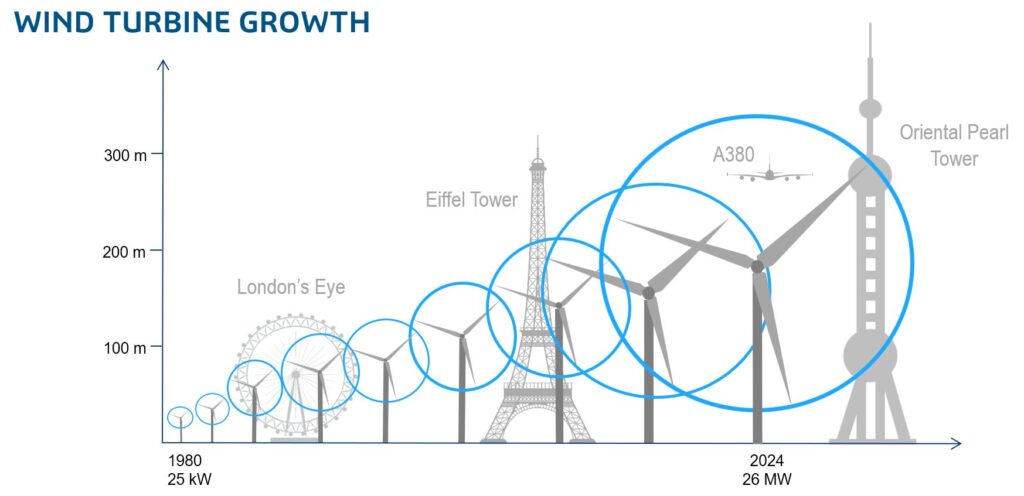

Wind power is one of the fastest-growing and most affordable energy sources worldwide. In 2023 alone, the world added 116 Gigawatts of wind capacity, driven by its low levelized cost of energy. This rapid expansion places more turbines closer to communities, intensifying scrutiny of their acoustic footprint.

Stricter noise regulations are now in effect globally. For example, some regions in Germany enforce nighttime noise limits as low as 35 dB(A) in residential areas. When turbines exceed these limits, operators are often forced to curtail power output, leading to a direct loss of revenue and clean energy production. Addressing noise is no longer just a matter of public relations; it is a commercial imperative.

This article presents a practical, simulation-based framework for predicting and mitigating wind turbine noise. We will detail two distinct workflows that address both aerodynamic and mechanical noise sources. You will see how this integrated approach allows for the design of quieter, more profitable turbines.

Understanding the Sources of Wind Turbine Noise

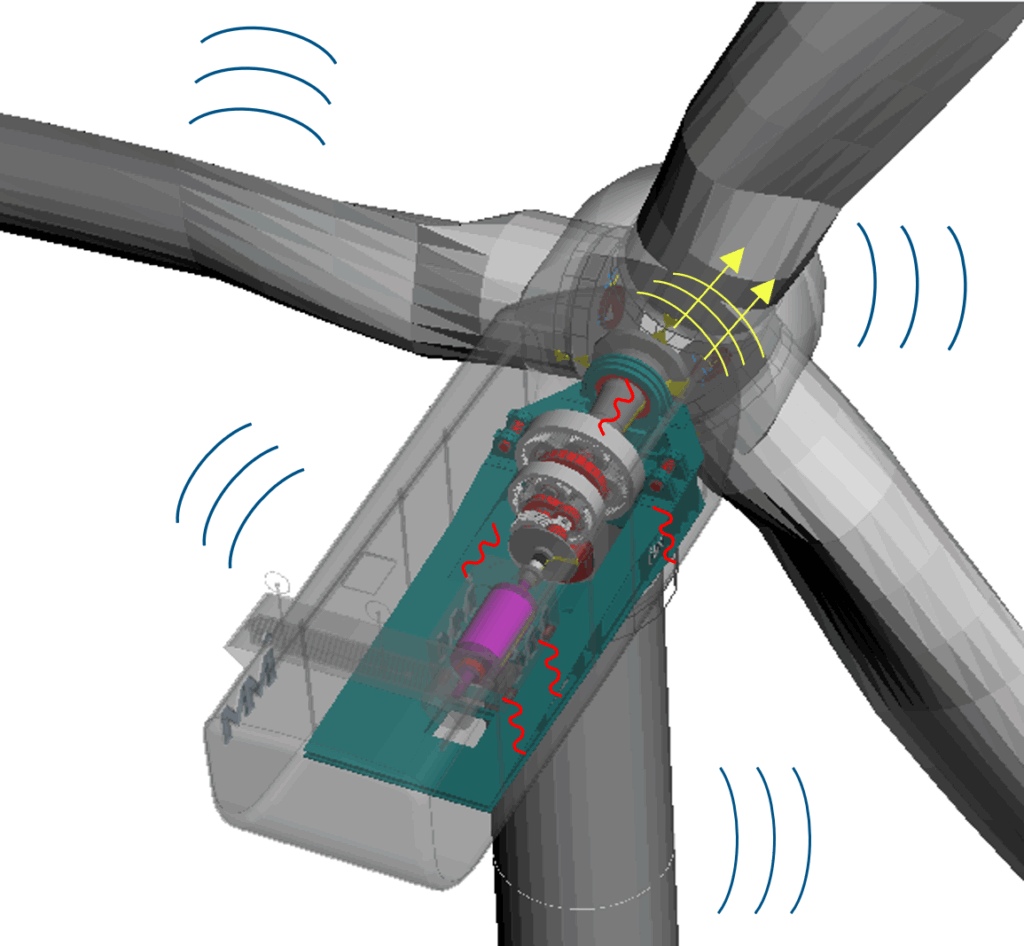

A turbine’s acoustic signature is complex. It is composed of two different types of noise that originate from separate sources.

- Aero-acoustic Noise: This is the broadband, “swooshing” sound produced by the turbine blades interacting with the air. The primary source is turbulence generated at the trailing edge of the blade. This is often the most significant contributor to the overall sound level.

- Vibro-acoustic Noise: This is a tonal, mechanical sound characterized by specific, narrow-band frequencies. It originates from vibrations in the drivetrain, mainly the gearbox and generator. These vibrations travel through the turbine’s structure and are radiated as sound by the tower, nacelle, and blades.

Historically, engineering efforts focused on reducing broadband aero-acoustic noise. As these efforts succeed, the previously masked tonal noises from the drivetrain or generator, for example, are no longer masked and are perceived as intrusive. An effective noise mitigation strategy must therefore address both sources.

Workflow 1: Mitigating Aero-Acoustic Noise

Prototyping and testing full-scale turbine blades is prohibitively expensive. Digital simulation provides a cost-effective and accurate alternative for optimizing aerodynamic and aero-acoustic performance. Our framework uses a validated workflow to design and test noise reduction features, such as trailing-edge serrations. For more information about the challenge of noise and noise regulations, which can be a limiting factor that constrains turbine operation, read the customer story from LM Wind Power and how they are working with Dassault Systèmes to pioneer simulation methods to address these challenges.

An Integrated Simulation Methodology

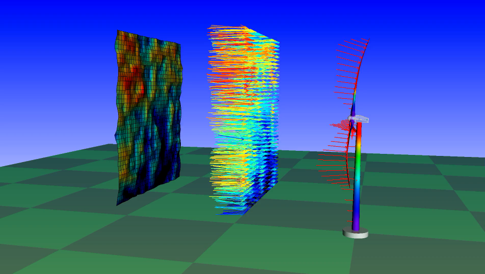

We conduct the aero-acoustic workflow on the 3DEXPERIENCE® platform. The process integrates blade design, aerodynamic analysis and acoustic prediction.

- Design: Blade geometry is created and optimized for performance using CATIA® and SIMULIA® products, utilizing a Blade Element Momentum Theory (BEMT) tool.

- Analysis: We use SIMULIA PowerFLOW®, a Lattice-Boltzmann method solver, to simulate the airflow around multiple blade sections. More specifically, we aim to resolve the turbulent boundary layer, which is of utmost importance for predicting the aeroacoustic wind turbine noise signature.

- Prediction: A Ffowcs Williams-Hawkings (FW-H) solver computes the far-field noise spectra for each individual section at virtual rotating microphone locations. The results are combined in a smart way, such that Doppler, ground reflection and atmospheric absorption are not neglected. This way, we create a virtual twin of the turbine, ensuring all conditions are met for an official IEC certification. This process is patent pending.

To balance accuracy and computational speed, we can use multi-fidelity approaches. A low-fidelity analysis first identifies the sections of the blade that generate the most noise. For a 5MW reference turbine, these are located around 75% and 92.5% of the blade’s radius. We then use a mid-fidelity “2.5D” (extruded airfoil) simulation on these critical sections. This method is approximately ten times faster than a full 3D simulation, yet delivers comparable accuracy, as outlined in various academic papers, making it ideal for iterating on, for example, serration designs.

Key Results and Design Insights

We tested two serration types (sharp and rounded tips) with different flap angles. The simulations measured noise at a standard IEC certification point: 100 meters downwind and 1.2 meters above the ground.

The results confirm the effectiveness, as well as the endless possibilities, of simulation-driven design.

- Significant Noise Reduction: All serration designs reduced noise at frequencies below 500 Hz.

- Optimal Configuration: A moderate flap angle of -5.5° provided the best performance, achieving a noise reduction of approximately 4 dB around the 200 Hz 1/3-octave band.

- Design Trade-offs: A more aggressive flap angle (-11°) reduced low-frequency noise but increased noise by 4 dB at 1 kHz. The moderate angle avoided this undesirable trade-off.

These findings show that targeted serration geometries can significantly reduce broadband noise in the most critical frequency ranges, directly impacting regulatory compliance.

Workflow 2: Analyzing Vibro-Acoustic Noise

As blades become quieter, the tonal hum from the drivetrain emerges as a primary concern. Predicting this noise requires a holistic system model that traces vibrations from their source through the entire turbine structure to the components that radiate sound.

A Holistic System-Level Approach

This workflow combines multibody system (MBS) simulation with vibro-acoustic analysis.

- Identify the Source: A main source of tonal noise is the gearbox. As gear teeth engage, the changing contact stiffness creates excitations known as Transmission Error (TE). While helical gears and micro-geometry corrections reduce TE, they cannot fully eliminate it across all the load conditions a turbine experiences.

- Model Vibration Paths: We use Simpack™ to build a high-fidelity MBS model of the entire wind turbine. This model features flexible Finite Element (FE) bodies for major components, primarily imported from Abaqus®, such as the tower, bedplate and blades. In addition, detailed representations of nonlinear elements, for example bearings, gear wheels and rotor blades, are also included. This allows us to accurately simulate how drivetrain vibrations propagate through various transfer paths to the radiating surfaces.

- Analyze Noise Radiation: The vibration data from Simpack is used as input for the vibro-acoustic software Wave6®. This tool calculates how the vibrations from the tower and nacelle radiate sound into the environment. The analysis uses a modal-based approach, which provides two key benefits:

- Speed: After an initial solve, we can rapidly assess the acoustic impact of different operating conditions or design changes by simply updating modal participation factors from the MBS model.

- Insight: The analysis reveals precisely how vibrations are transferred through the mechanical system and how much each structural mode of the tower or nacelle contributes to the sound pressure level. This helps engineers pinpoint problematic resonances and develop mitigation solutions.

Enabling Secure Collaboration with IP Protection

Building a complete system model requires close collaboration between the turbine OEM and various component suppliers. This presents a challenge regarding the protection of sensitive intellectual property (IP).

Our framework addresses this with a “BlackBox” export function in Simpack. A supplier can provide their subsystem, such as a gearbox, as a binary, fully functional model. The OEM can integrate this BlackBox into their holistic system simulation without having access to proprietary design details. The supplier maintains complete control over their IP, while the OEM gains the accuracy needed for system-level analysis. This capability facilitates secure and effective collaboration.

Connecting Simulation to Commercial Outcomes

This integrated, multi-disciplinary framework translates directly into commercial advantages for developers, owners and operators.

- Reduce Revenue Loss: By designing quieter turbines that comply with strict noise limits, operators can avoid costly nighttime power curtailments and maximize annual energy production.

- Accelerate Certification: Virtual testing allows engineers to evaluate designs against certification standards early in the process, reducing the risk of expensive delays and late-stage modifications.

- Lower Development Costs: Efficient simulation workflows reduce the reliance on building and testing expensive physical prototypes, lowering capital expenditures.

- Improve Community Acceptance: Proactively managing the acoustic footprint helps build trust and support in communities where wind farms are located.

The Future: Adaptive Noise Control

The methods detailed here provide a robust and validated framework for engineering quieter wind turbines today. Explore the presentation from GE Renewable Energy in the SIMULIA Community: GE Renewable Energy: Simulation-Based Wind Turbine Gearbox Tonality Analysis and Risk Assessment | Wind & Drivetrain Conference 2022 for more information about tonal noise from machinery and drivetrain components.

Looking forward, the next step is to fuse these high-fidelity simulations with real-time operational data from the field. This synthesis will enable the development of adaptive noise control systems. Such systems could adjust a turbine’s operational parameters in real time to minimize its acoustic signature under specific wind and atmospheric conditions, further enhancing efficiency and community relations.

By continuing to advance our simulation capabilities, we can ensure that wind energy remains a clean, affordable and acceptable source of power for the future.

Ready to design quieter and more profitable wind turbines? Contact our team to explore how this multidisciplinary simulation framework can help you achieve your noise mitigation goals, and register for the upcoming webinar, Wind Turbine Noise Reduction.

Interested in the latest in simulation? Looking for advice and best practices? Want to discuss simulation with fellow users and Dassault Systèmes experts? The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.