Understanding the SAW Gas Pressure Sensor

The SAW sensor at the heart of this study is built upon a piezoelectric material, such as LiNbO3, deposited on a substrate. Metallic film reflectors are placed at both ends of the piezoelectric layer, with inter-digital transducers (IDTs) in the middle. A crucial component for gas sensing is the absorption layer of Polyisobutylene (PIB) on top of the IDTs, designed to capture target gas molecules, such as dichloromethane (DCM). The sensor’s sensitivity is determined by the minimum mass of DCM molecules that must be absorbed to cause a detectable shift in resonant frequency.

SAW sensors operate on the principle that surface acoustic waves propagating along a piezoelectric substrate are affected by external forces or mass changes on the material’s surface. This interaction leads to a measurable change in the sensor’s output, making them ideal for gas and chemical sensing, pressure sensing, temperature sensing and biomedical applications.

The Power of Simulation in SAW Sensor Design

Simulating SAW sensors is critical for understanding and optimizing their behavior. Our approach employs finite element analysis (FEA) to model the sensor’s structure and predict resonant frequencies under varying load masses. The simulation workflow, from initial model creation in CST Studio Suite to FEA in Abaqus, provides a virtual environment for detailed analysis, optimization and testing, leading to more efficient and reliable sensor designs.

Our Comprehensive Simulation Workflow

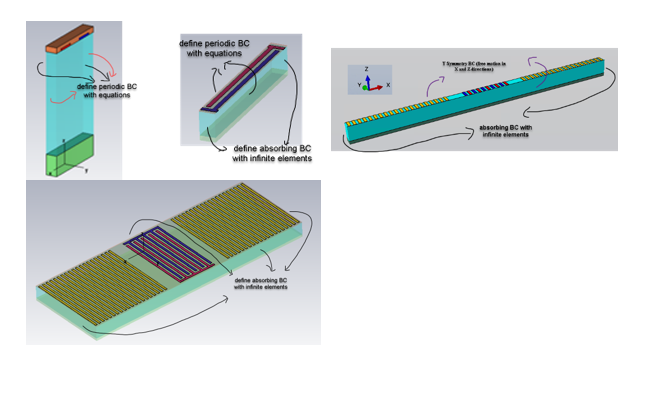

Our simulation strategy involves several levels of model simplification, from a unit cell to a complete 3D model, offering flexibility to designers. We employed three primary methods to detect the resonant frequency:

- Eigenmode Solver: Used to identify natural modes directly.

- Steady-State Direct (SSD) Solver: Sweeps a frequency range to pinpoint peak displacement or kinetic energy for resonances. This method was applied across unit-cell, 2D full-length and full 3D models.

- Dynamic-Implicit Solver: Conducts transient analysis with a short pulse excitation, followed by a Fast-Fourier Transform (FFT) of the time response to reveal resonances.

Key Simulation Studies and Findings:

- Basic Unit-Cell Model (Study a): We defined piezoelectric material properties and applied periodic boundary conditions. Simulations showed that increasing the PIB layer’s mass by 1% and 10% shifted the resonances down by 1.1 MHz and 10 MHz, respectively.

- Extended 3D Unit-Cell SSD (Study b): This model incorporated bus-bars and absorbing boundaries. While the absolute resonant frequency shifted slightly due to relaxed mesh density and absorbing boundaries, the sensitivity to mass load remained consistent with previous findings.

- Full-Length Model (Study c): To account for delay lines and reflectors, a simplified one-cell thickness model was used. SSD analysis proved effective here, revealing multiple resonances due to surface and body waves. Doubling the number of reflector strips impacted the quality factor and introduced more resonances.

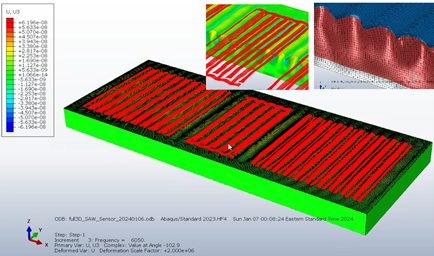

- Full 3D Model (Study d): While computationally intensive, the full 3D model provides a detailed analysis of wave-substrate interactions, reflections and superpositions, enabling precise adjustment of designed resonances and reduction of unwanted ones.

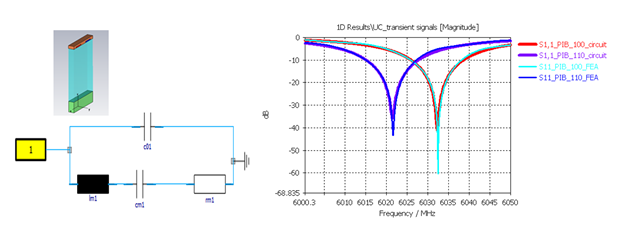

Extracting Electrical Characteristics

A key aspect of our workflow involves extracting impedance and S-parameters from simulation results. This data is essential for system-level electromagnetic analysis, signal matching, transducer efficiency and noise reduction. We can extract Butterworth-Van Dyke (BVD) equivalent circuit parameters, which provide designers with intuitive information and can be used for early-stage system-level design. For more complex models, direct use of S-parameters or a modified BVD circuit is recommended for higher accuracy.

Conclusion: A Holistic Approach to MEMS SAW Sensor Design

Our comprehensive multiphysics MEMS simulation workflow, utilizing SIMULIA Abaqus and SIMULIA CST Studio Suite, provides a complete solution spanning from CAD modeling to FEM analysis for SAW chemical gas pressure sensors. By employing various state-of-the-art solvers and providing different levels of model simplification, designers gain invaluable insights into sensor behavior, including sensitivity to mass changes and the identification of unwanted resonances. This approach ultimately leads to cost-effective development, optimized designs and accelerated innovation in the field of MEMS SAW sensors.

Interested in the latest in simulation? Looking for advice and best practices? Want to discuss simulation with fellow users and Dassault Systèmes experts? The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.