I spent a total of five years in AIESEC, the world’s largest student-run organization. My last year there was as Global Chief Information Officer—I was responsible for enabling the operations of the 50,000-student organization via digital technology. It was an opportunity for me to help accelerate AIESEC’s mission of fulfilling humankind’s potential. It was also the time when I was first exposed to the concept of sustainability, thanks to renowned economist Gunter Pauli. Since then, the connection between digital and how it can create a positive impact on the world became imperative for the rest of my career.

In 2015, I joined Dassault Systèmes (3DS), more specifically the DELMIA brand, whose portfolio helps industries by connecting the virtual and real worlds of value networks to collaborate, model, optimize, and perform in the ambit of manufacturing and operations. The potential to enable change in the market has become a key pillar in the go-to-market approach to enable more sustainable operations.

What Sustainable Operations Mean?

Sustainable operations refers to the orchestration of value: capture, retention, and creation through manufacturing products and their associated supply chain management. It encompasses economically sound and socially responsible processes that strive to eliminate negative environmental impacts while conserving energy and regenerating natural resources. It focuses on achieving progress that enhances the effectiveness and efficiency of a value network as a whole, considering human, environmental, and economic dimensions. It also involves different domains of action, such as people, product, process, technology, and industry.

This is DELMIA’s role — and the “Why” of it is substantial. Different actors drive this change; the industry’s status quo is being challenged by regulators, a growing mass of responsible consumers, and the need to better understand the explicit risk sustainability represents for businesses to continue operating under the status quo. At the business level, sustainability is becoming the most critical lever for strategy. It is shaping a new set of values that companies must embrace to ensure relevancy, conquer new markets, prepare their workforce for the future, and become part of the solution.

Sustainability Challenges

When considering the typical challenges we cater for from our digital capabilities perspective, in connection to sustainability, you need to think of the lack of resilience in current value chains. This is revealed by disruptive forces, as evidenced by the impact of the COVID-19 crisis as well as increasing complexity—within and around the supply chain, technology, rules and regulations, and consumer demands. The fact that we continue to run an economy that assumes infinite stocks of materials and resources implies a clear materials supply risk translated visibly in the volatility of raw material prices. Another challenge, less spoken about, that we consider is the lack of understanding of the role that digital can play in enabling and accelerating sustainable ambitions.

To advance this understanding in the industry, a research paper was published from a recent collaboration between Accenture and Dassault Systèmes. The study unveiled a number of use cases on how virtual twins and capabilities such as those DELMIA has to offer play a pivotal role in enabling and accelerating sustainability.

As an example, here is one use case that links these two worlds:

Use Case: Optimization of material flows and waste valorization

Driving the concept of the circular economy forward means having the right information to improve the use of materials and identify waste streams that can be converted to resources and reused. To measure and improve resource productivity, dynamic, end-to-end visibility of material flows is fundamental. Though it is broadly established that less material-intensive sectors have higher rates of productivity by measuring material intensity at the macroeconomic level, only a few organizations are practicing this to inform their circular economy or sustainability strategies. With virtual twin technologies, data can be consolidated from each stage of the product and production lifecycles, allowing users to weave information together and analyze it to identify opportunities for improvement, track performance, and inform decisions. Virtual twin technologies can be used to operationalize targets to become more material and resource efficient and drive financial benefits, including valorizing waste streams — this is particularly relevant for material- and energy-intensive businesses involved in the production of intermediate goods, like the metals industry.

There are strong indications (I hope) that the world is headed towards a more sustainable trajectory from all aspects, and industry plays a crucial part in enabling and advancing this. There is enough evidence in the world of operations, and beyond, that virtual twin solutions will drive sustainability pathways for those who are ready to embrace them. Tapping into the potential of such technologies presents a wealth of essential economic opportunities to not only advance environmentally but, ultimately, to build operational excellence and organizational resiliency.

How Virtual Twins Accelerate Sustainable Operations and Circular Ambitions

I would like to invite you to listen to a webcast, in partnership with GreenBiz and Accenture that we recently hosted, titled “ How Virtual Twins Accelerate Sustainable Operations and Circular Ambitions .” You’ll hear from senior experts on the potential of virtual twin technologies to enable more sustainable operations and the transition towards a more circular economy. We discussed:

- How virtual twins can help overcome barriers to achieving sustainability and circular economy goals.

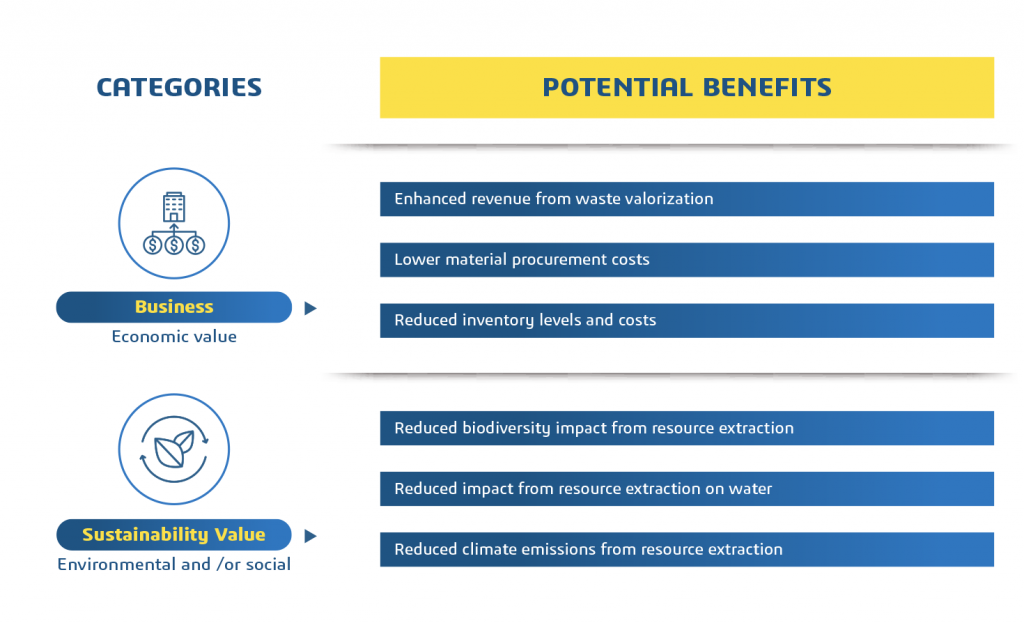

- The economic and environmental benefits of adopting virtual twins in operations.

- Technology use cases and industry applications of virtual twins in manufacturing, supply chain planning and optimization for waste valorization, the recovery of parts and materials for decommissioned assets, and more.

To learn more about the various use cases of virtual twin technologies, and their benefits, in driving more sustainable operations, download the research paper: Designing Disruption: The Critical Role of Virtual Twins in Accelerating Sustainability