For the entire series, read part 1.and part 3..

Introduction

When steelmakers plan to expand crude steel capacity, modernize rolling mills, or align with decarbonization mandates, one critical question arises: should they build a greenfield steel plant from scratch, or upgrade an existing brownfield facility?

Both paths can unlock growth, efficiency, and competitiveness — but the right choice depends on your market strategy, CAPEX availability, and long-term vision. In this article, we’ll break down when to choose each option, the trade-offs involved, and how Digital Twin steel plant models are reshaping decision-making for EPC firms, plant owners, and operations leaders.

Why the Greenfield vs. Brownfield Decision Matters in Steel

Choosing between greenfield and brownfield projects is not simply a technical or financial calculation — it’s a strategic industry decision with far-reaching consequences.

- Capital Costs: A greenfield integrated steel plant may require billions in CAPEX for coke ovens, sinter plants, blast furnaces, basic oxygen furnaces (BOFs), EAFs, oxygen generation units, and downstream mills. Brownfield revamps, by contrast, leverage existing coke batteries, utilities, and logistics to reduce initial spend.

- Time to Market: Brownfield expansions bring faster results, often critical when meeting surging demand in flat or long products. Greenfields are multi-year undertakings, sometimes spanning 5–7 years before full commissioning.

- Sustainability Pressure: With steel responsible for ~7–8% of global CO₂ emissions, decarbonization is no longer optional. Greenfields allow plants to be designed around hydrogen DRI, scrap-EAF routes, or carbon capture, while brownfields require complex retrofits to cut emissions.

- Risk Profile: Greenfields face permitting hurdles and high financing risks, while brownfields must navigate downtime, integration of legacy assets, and operational disruptions.

The decision ultimately shapes whether your plant remains competitive for the next 20–30 years.

When to Choose a Greenfield Steel Plant

A greenfield project involves building an entirely new plant on undeveloped land. Though costly and time-intensive, it offers unparalleled flexibility.

✅ Best Scenarios for Greenfield Steel Plants

- Market Entry: Entering a new region or export hub without existing facilities.

- Capacity at Scale: Demand forecasts justify a multi-million-tonne integrated steel complex.

- Decarbonization Pathways: Build hydrogen-ready direct reduction (H₂-DRI) modules, EAFs, and renewable-powered utilities from scratch.

- Technology-First Design: Full integration of robotics, AI-driven casting control, smart rolling schedules, and Digital Twin meltshop and mill models.

⚠️ Risks and Challenges

- High CAPEX: Land acquisition, utilities (power, water, oxygen), rail connectivity, and construction of coke ovens, pellet plants, and mills.

- Long Lead Times: Multi-year commissioning before revenue generation.

- Regulatory Complexity: Environmental clearances, especially for large blast furnace projects.

When to Choose a Brownfield Steel Plant

A brownfield project focuses on expanding or modernizing an existing site. Though constrained by legacy layouts, it is faster and more capital-efficient.

✅ Best Scenarios for Brownfield Steel Plants

- Fast Time-to-Market: Adding a new caster, revamping a hot strip mill, or installing a new EAF can be done in months.

- Capital Efficiency: Leverage existing coke ovens, power plants, and rail yards.

- Strategic Locations: Plants near iron ore mines, ports, or skilled workforce hubs are prime for upgrades.

- Incremental Modernization: Stepwise adoption of automation, predictive maintenance, and emissions controls.

⚠️ Risks and Challenges

- Integration Issues: Fitting modern BOF gas recovery or advanced control systems into a 30-year-old mill layout.

- Operational Disruption: Blast furnace relines or caster upgrades often demand shutdowns.

- Sustainability Constraints: Retrofitting CO₂ reduction systems may not reach net-zero targets.

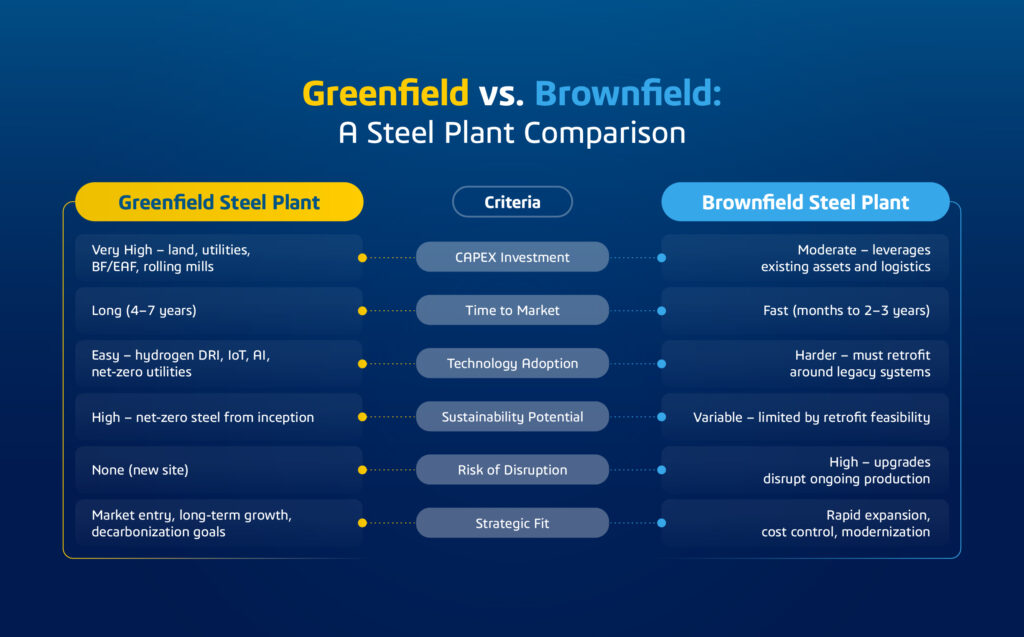

Greenfield vs. Brownfield: A Steel Plant Comparison

Key Factors in the Decision

- Market Timing

- Short-term demand → Brownfield.

- Long-term positioning → Greenfield.

- CAPEX vs. OPEX

- Greenfields cost more upfront but reduce OPEX via energy-efficient layouts.

- Brownfields cut CAPEX but may carry higher long-term OPEX.

- Sustainability Goals

- Greenfield → hydrogen-ready, carbon capture integrated, renewable-powered.

- Brownfield → extend life of existing assets, incremental CO₂ reductions.

- Operational Risks

- Can the plant withstand furnace shutdowns or mill downtime during upgrades?

- Workforce & Logistics

- Brownfield → benefit from trained operators and proven supply chains.

- Greenfield → requires workforce development and new logistics integration.

How Digital Twins Transform Decision-Making

In Greenfield Steel Plants

- Virtual Plant Design: Optimize blast furnace siting, raw material yard logistics, and mill flows.

- 4D/5D BIM: Link design to construction schedules and CAPEX forecasts.

- Virtual Commissioning: Simulate BOF-converter tapping, casting sequences, and rolling schedules before start-up.

In Brownfield Steel Plants

- 3D As-Is Capture: Scan existing furnace shells, casters, and mill bays to avoid retrofit clashes.

- Upgrade Simulations: Model furnace relines, secondary metallurgy retrofits, or emissions-control systems before shutdown.

- Shutdown Optimization: Use predictive analytics to reduce outage duration during revamps.

By embedding Digital Twins in EPC execution, all stakeholders — from steelmakers to contractors — work from a single source of truth, reducing rework and risk.

Case Examples: How Steelmakers Apply Each Path

- Greenfield Example – Hydrogen-DRI in Europe

A major European steel producer is building a €2 billion hydrogen-based DRI plant and EAF complex. The new greenfield facility is designed from scratch to run on renewable power, integrate a full Digital Twin control system, and support net-zero steelmaking. The payoff: a long-term competitive edge in supplying green steel to the automotive sector. - Brownfield Example – Fast-Track Expansion in India

An Indian steelmaker expanded capacity by revamping a blast furnace and installing a new continuous caster at an existing integrated plant. Using 3D scanning and predictive maintenance tools, the EPC team kept downtime minimal while adding over 3 million tonnes of annual steel output in less than two years — a textbook example of brownfield agility.

Conclusion

The choice between a greenfield and brownfield project is a strategic lever for steel producers:

- Greenfield = freedom, cutting-edge design, hydrogen-ready infrastructure, high CAPEX, long timelines.

- Brownfield = speed, capital efficiency, asset modernization, but constrained by legacy systems and downtime risks.

Both will play a decisive role as the global steel industry transitions toward low-carbon production, digital transformation, and sustainable competitiveness.

👉 In our next blog, we’ll explore: How Digital Twins Transform Greenfield and Brownfield Projects — showing how EPCs and steel plant owners can cut risks, shorten schedules, and design future-ready facilities.

📘 For practical strategies, download our free ebook: Greenfield to Brownfield: Reinventing Steel Plants with Digital Twins.