We spoke with Jakob Møller, CAD Specialist at Grundfos, to learn how CATIA and the 3DEXPERIENCE platform are empowering teams to design smarter, simulate faster, and connect every step of the product lifecycle—from concept to end of life.

Engineering Efficiency: How Grundfos Designs the World’s Most Sustainable Pumps

For more than seven decades, Grundfos has shaped the global water solutions industry, producing millions of pumps that deliver water efficiently and sustainably to communities around the world. With nearly 20,000 employees operating across continents, its mission is simple yet vital: make water work smarter.

At the heart of this mission lies a technical challenge that drives every design decision: efficiency. Whether optimizing hydraulic performance or motor dynamics, every percentage point counts.

“Grundfos is a water solution company,” Jakob explains. “We do a lot of pumps to ensure that everyone gets water and takes care of the water in the best possible way.”

Design Automation and EKL: The Power Behind Efficient Pump Innovation

For Grundfos engineers, CATIA has long been the cornerstone of design excellence. With over 35 years of experience using CATIA, the company continues to push the boundaries of what’s possible—combining advanced surface modeling, design automation, and simulation-driven validation to maximize product efficiency and sustainability.

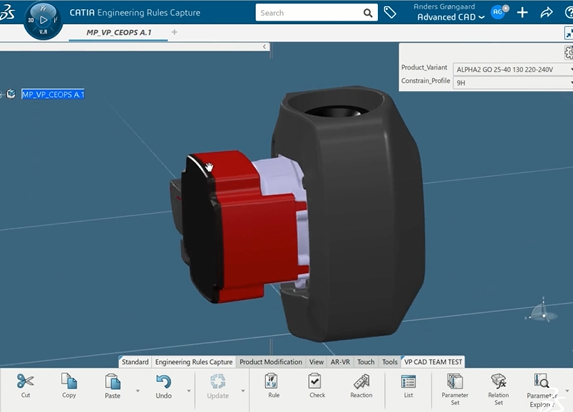

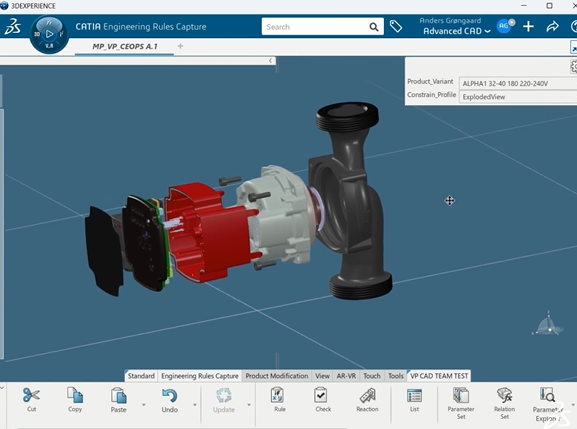

A key differentiator for Grundfos is its extensive use of parametric templates and rule-based design powered by EKL (Engineering Knowledge Language). This approach allows engineers to configure and generate thousands of pump variants directly within CATIA, dramatically accelerating design iterations across a vast product portfolio.

“We have parametric products that enable us to build thousands of products instantly. That means we can do design sweeps or design reviews, even for simple components, across a vast product program.”

Through this high level of automation, Grundfos can perform rapid design evaluations and simulations early in development, ensuring that each design meets hydraulic and motor efficiency targets before physical prototyping. CATIA’s surface design tools play a crucial role in refining pump geometries to achieve optimal fluid dynamics — often making the difference between average and best-in-class energy performance.

By integrating design, automation, and simulation into one workflow, Grundfos not only reduces time-to-market but also embeds sustainability directly into its engineering process.

Creating a Digital Thread: Connecting Design, Simulation, and Manufacturing

Grundfos’ next major step is its transition to the 3DEXPERIENCE platform, integrating CATIA, ENOVIA, and DELMIA into one digital ecosystem.

We’ve been through an extensive vendor selection program and ended up with CATIA and 3DEXPERIENCE. We’ve had a good collaboration and partnership for a long time.

The goal is ambitious but clear: to establish a complete digital thread—connecting design, simulation, systems engineering, and manufacturing into one seamless workflow.

This connected approach will not only accelerate development cycles but also ensure that every design decision is informed by real-world data, improving both performance and sustainability.

Embracing Systems Engineering: A Cultural Shift Toward Model-Based Collaboration

Beyond tools and processes, Grundfos is embracing a fundamental cultural shift—one built on systems engineering and collaboration.

By integrating CATIA Magic into its workflow, Grundfos is laying the groundwork for a model-based systems engineering (MBSE) approach that will unify requirements, design, and verification within a single digital framework. This new way of working empowers teams to think holistically, ensuring that efficiency, sustainability, and innovation are embedded from day one.

Conclusion

Grundfos’ journey with CATIA and the 3DEXPERIENCE platform exemplifies the future of digital engineering—one where sustainability, innovation, and collaboration flow seamlessly together. By uniting decades of design expertise with a fully connected digital ecosystem, Grundfos is not only building more efficient pumps—it’s pioneering a smarter, more sustainable world of water management.

FAQ

1) How is Grundfos using CATIA and the 3DEXPERIENCE platform to drive sustainable innovation?

Grundfos uses CATIA and the 3DEXPERIENCE platform to create a connected digital engineering process that links design, simulation, and manufacturing in a single environment. By combining advanced surface modeling, rule-based design with EKL, templatization and simulation-driven validation, engineers can optimize pump efficiency and energy performance early in development—reducing material waste, physical testing, and time-to-market.

2) Why is efficiency such a critical focus in Grundfos’ product design?

Efficiency is at the heart of Grundfos’ mission to make water work smarter. Every improvement in pump performance, hydraulic dynamics, or energy consumption directly contributes to global sustainability goals, reducing environmental impact while enhancing product reliability and customer value.

3) How does CATIA enable faster and smarter product design at Grundfos?

Through extensive use of parametric and knowledge-based design powered by EKL, Grundfos engineers can automatically generate and evaluate thousands of pump variants directly in CATIA. This high level of automation—combined with integrated simulation and precision surface modeling—accelerates development, ensures consistent quality, and drives continuous innovation in hydraulic efficiency.

4) What role does the 3DEXPERIENCE platform play in connecting design and manufacturing?

The 3DEXPERIENCE platform integrates CATIA, ENOVIA, and DELMIA into one collaborative ecosystem. This digital thread ensures that all teams—design, engineering, and manufacturing—work from a single source of truth, enabling seamless data continuity, faster iteration, and informed, sustainable decision-making.

5) How is Grundfos transforming its engineering culture through systems thinking and collaboration?

By adopting CATIA Magic and a model-based systems engineering (MBSE) approach, Grundfos unifies requirements, design, and verification. This shift fosters cross-functional collaboration, holistic thinking, and a stronger focus on sustainability, embedding innovation into every phase of product development.