Packaging covers products to protect them during storage, transportation, distribution, and use. In addition to being a physical enclosure against shocks, temperature changes, and pressure changes, it can also act as a barrier against oxidizing agents. Lastly, it serves as an information and marketing tool.

Packaging Development and New Trends

The main steps for developing new packaging include:

- Research: choose the material (often a polymer film) and design it;

- Development: characterize the materials and evaluate their physical and chemical properties, potential impact on the environment, the safety and the regulatory issues of the material on a laboratory (pilot) scale;

- Manufacturing: produce it on a large scale following the guidance of Manufacturing Quality Control software.

Choosing the material for packaging is a long process. Commonly used materials are paper and cardboard, plastics, metals and glass. Plastics corresponded to almost half of the worldwide packaging demand in 2019, counting approximately 44%1. The production of plastics nowadays is larger than the amount the world can deal with big part of it is single use, being disposed in the environment in a matter of minutes after usage, but staying in nature for hundreds of years. Consequently, the idea of sustainability emerges with the necessity for changes in these materials, urging for innovative, recyclable, renewable, and degradable components.

The answers to this challenge must come fast, considering the new consumers’ desires, the volatility of the supply chain, and the consequences to living beings for releasing non-degradable plastics into the environment2. Therefore, simulation and modeling appear as powerful tools to fight against this issue rapidly, including benefits such as enhancing the discovery of new substances, and reducing, not only resources used in the laboratory, but also the time applied in the numerous necessary physical tests.

BIOVIA as a Laboratory and Industry Solution Tool

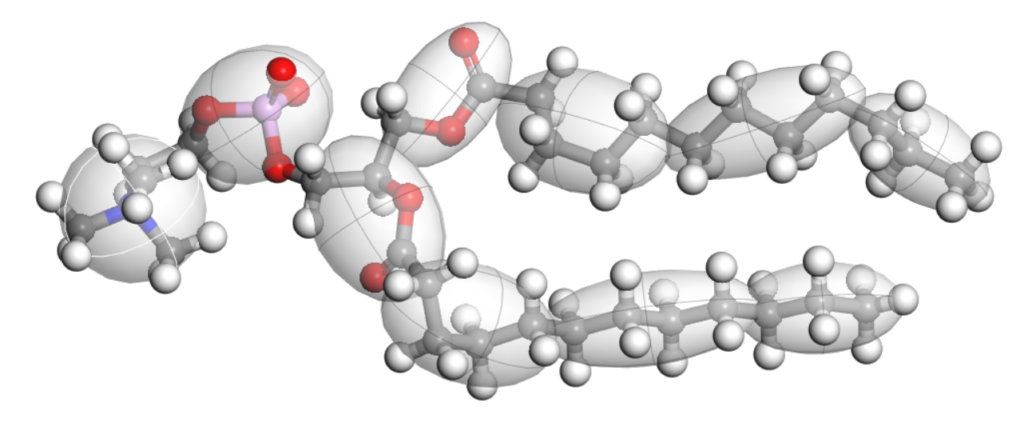

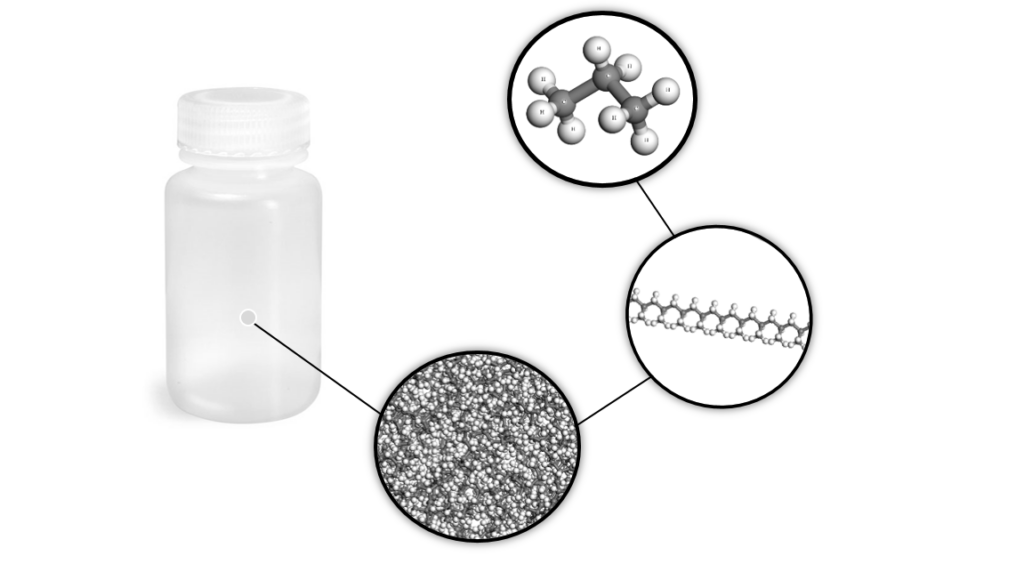

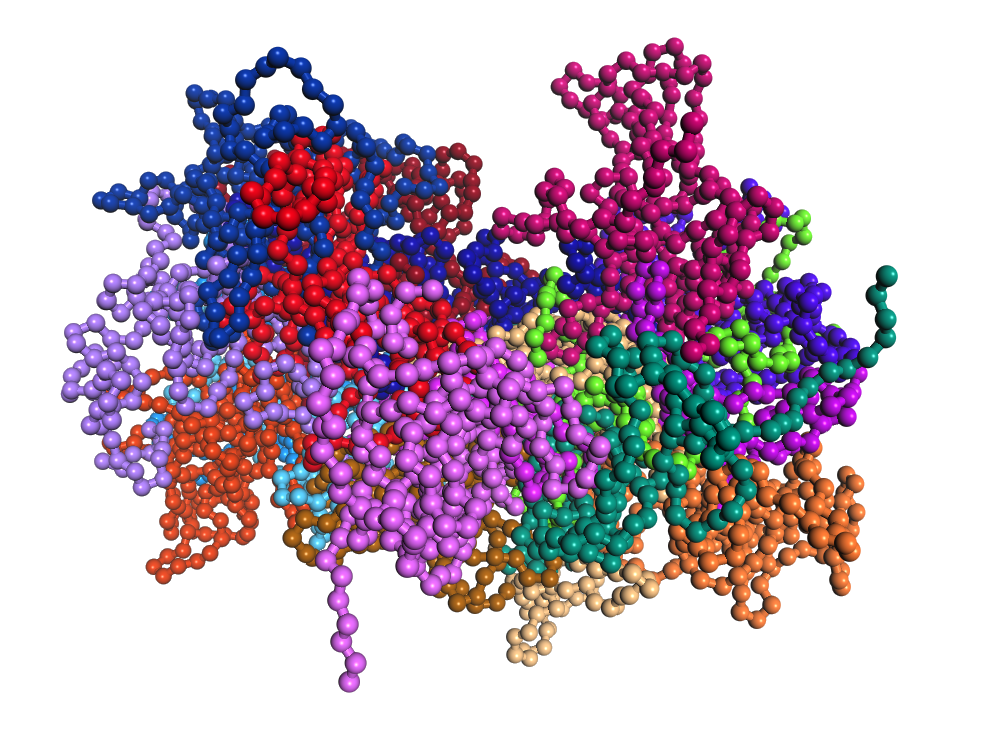

BIOVIA Materials Studio® (MS) is a modelling and simulation tool from Dassault Systèmes that provides a list of diverse modules to model different materials, to study their properties, and analyze their behavior. Simulation scales typically go from the atomistic to the meso-scale. Atomistic models give more detailed insights, thus it is a good option to investigate the structure of molecules, internal energy, bonds and angles, for example. While mesostructures are employed for larger systems (Figure 1).

MS Mesocite can model and simulate mesostructures, making it possible to study complex configurations with many components. Such models would be challenging at the atomistic scale in terms of time and system length. In atomic scale, it is necessary to account for every interaction between all atoms in the system; however, at the mesoscale (i.e. coarse-grained models4), the atoms are grouped together, this reducing the degrees of freedom and the system accounts only the interaction between the groups, which greatly decreases the computational cost.

1b. This simplification enables simulations of large-scale systems such as membranes, soft matter, and biopolymers.

To bring a real molecule to a virtual environment, we implement an Interatomic Potential, commonly called a Forcefield, which is a combination of parameters that will determine how the beads interact. These parameters consist of bonded terms (intramolecular interactions) and non-bonded terms (intermolecular interactions). In order to determine and validate these specifications, simulations are performed, and the results are compared with experimental results.

Once the parameters are validated against experimental results, the Forcefield is ready and can be applied in other studies with similar chemical systems.

The Martini forcefield was first published in 2007, with the primary aim to simulate complex biomolecules5. In 2021, Martini 3.0 was published as a promising updated version, now broadly extended to other types of chemicals, such as polymers, combining parameters with 11 levels that go from hyper attractive to super repulsive non-bonded interactions6.

Polymers as a Case Study

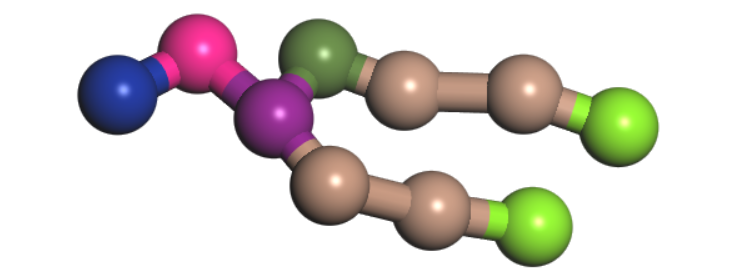

After polyethylene, polypropylene is the most demanded polymer in the packaging industry7. It is one of the simplest homopolymers, and the repeat unit is propylene (Figure 2). Understanding its molecular structure, its mechanical and chemical properties, and its interactions with other molecules is pertinent not only to manufacture products based on it, but also to developing new materials with the equivalent or even enhanced properties.

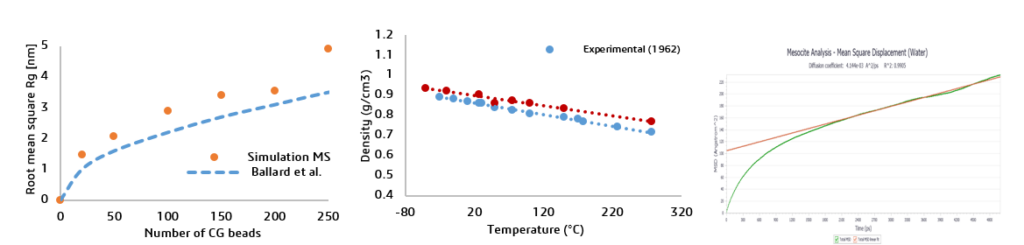

Materials Studio Mesoscale Simulations were run using MS Mesocite, employing both NVT and NPT ensembles, to develop a tailored Forcefield based on Martini 3.0, which would be specific to polypropylene beads (Figure 3). We studied the influence of Coarse-Grained beads number on the radius of gyration (Rg) and the density variation with the temperature. These results were compared to experimental data in order to validate the newly developed Forcefield (Figure 4).

Next, we looked at other common properties that could meet the needs of the packaging industry such as the Water Vapor Transmission Rate (WVTR) and Oxygen Permeation (OP). Both of these are critical for preserving stored goods, as well as for elongation at break, which may be relevant to polymer production or transportation.

Polypropylene is a non-biodegradable petroleum-based polymer with a high oxygen diffusion and a low water vapor permeation. The new tendency of the market is to find biobased and biodegradable polymers with equivalent or superior advantages compared to the old ones. The same step-by-step computational method applied to simpler polymers is now being extended to more complex frameworks, such as Polylactic acid (PLA) and Polyglycolide (PGA) BIOVIA Materials Studio® Dassault Systèmes offers an advanced environment for discovery and analysis In Silico of materials and their performance. Using this solution, excessive laboratory experiments are minimized, resources are preserved, costs are reduced, time-to-market is improved, and innovations are brought quickly to market.

Sources:

- Statista. Distribution of packaging demand worldwide in 2019, by material type. Available in https://www.statista.com/statistics/271601/packaging-materials-in-the-global-packaging-market-since-2003/

- National Geographic. The world’s plastic pollution crisis explained. 2019. Available in https://www.nationalgeographic.com/environment/article/plastic-pollution

- BIOVIA Reference Database. Molecular Modeling and Simulation. Available in https://www.3ds.com/products-services/biovia/references/

- Casalini, Tommaso. “Fundamentals and application of modeling in support of spinal cord injury repair strategies.” Spinal Cord Injury (SCI) Repair Strategies. Woodhead Publishing, 2020. 279-306.

- Marrink, Siewert J., et al. “The MARTINI force field: coarse grained model for biomolecular simulations.” The journal of physical chemistry B 111.27 (2007): 7812-7824.

- Souza, Paulo CT, et al. “Martini 3: a general purpose force field for coarse-grained molecular dynamics.” Nature methods 18.4 (2021): 382-388.

- World Economic Forum. Setting the facts straight on plastics. Available in https://www.weforum.org/agenda/2019/10/plastics-what-are-they-explainer/