Optimizing Rail Industry Safety with SIMULIA Simpack Advanced Simulation

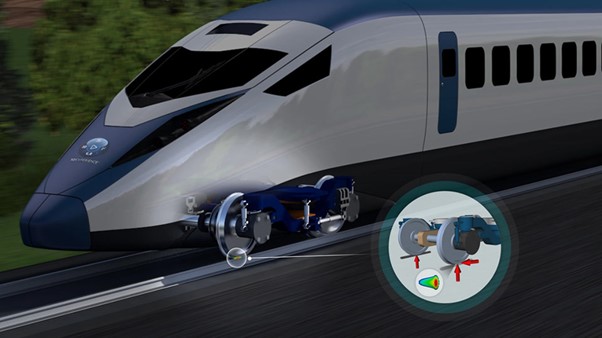

What if you could simulate real-world conditions, like a train passing through a switch or the effects of a crosswind? Dassault Systèmes’ SIMULIA Simpack utilizes virtual twin technologies and data-driven simulations to enable engineers to conduct Multibody Simulation (MBS) analyses, covering derailment prevention, rail-wheel wear analysis, comfort assessment and critical speed analysis. This simulation-based approach allows engineers to address critical operational issues and enhance rail freight safety and reliability — all before implementation in the real world. Simpack models are complete rail vehicle systems that incorporate wheel-rail contact, suspension components, bogie structure and track deformations.

With Simpack Rail, railroad operators can:

• Analyze rail vehicle dynamics to predict non-linear behavior

• Optimize suspension and wheel-rail interaction to improve safety and reduce maintenance costs

• Simulate extreme conditions to prevent serious accidents on railway systems

How Does Train Simulation Work?

With rail freight traffic projected to reach 13,800 trains per day by 2050, operators face an urgent need to operate sustainably in a competitive landscape. Advanced simulation technology provides real-time insights for safe, reliable and efficient rail operations of tomorrow. Read about how today’s rail operations will meet tomorrow’s demands, and learn more about high precision solutions with simulation-driven testing in our white paper: https://discover.3ds.com/business-services-virtual-twins-for-rail-simulation.

Five Ways SIMULIA Simpack Contributes to Rail Freight Safety

- Derailment Prevention through Curve Passing Analysis

Reducing derailment risks, particularly when maneuvering through curves at varying speeds, is crucial for train safety. Common causes include excessive lateral forces, unbalanced loading, and improper track alignment. For instance, freight cars with too stiff suspensions are particularly vulnerable to derailments on uneven tracks or sharp curves.

SIMULIA Simpack enables engineers to conduct curve-passage analysis using the system’s mass properties, suspension characteristics, wheel and rail profiles, and track geometry as inputs. Analysts can generate a Design of Experiments (DOE) sequence to test different vehicle configurations navigating curves. This collaborative analysis enables rail operators to simulate derailment scenarios under realistic conditions. The stability of the train across different configurations and track types can therefore be evaluated.

FOCUS: Simpack Solver calculates derailment coefficient and wheel raise as output to determine the velocity thresholds at which derailment might occur. Engineers can then optimize vehicle design and running velocity to reduce derailment risk. In addition, by identifying factors contributing to derailment risks, engineers can enhance design and maintenance strategies to ensure compliance with standards such as EN 14363.

- Wheel-Rail Interaction and Wear Analysis

Wheel wear directly impacts maintenance costs and rail safety. Using SIMULIA Simpack, engineers can estimate wear by considering various rail and wheel profiles and vehicle parameters to develop optimal designs that extend service life and reduce maintenance costs. Operators can also assess the amount of wear and accumulation under different load conditions. If the analytical tool reveals severe local wear on the wheel, it indicates the need to change and optimize the track-wheel interaction.

- Structural Fatigue Life Assessment

Rail vehicle components undergo continuous loading, resulting in fatigue-related failures over time. Simpack, integrated with a fatigue analysis tool, enables engineers to conduct life-damage analysis, estimate stress accumulation, and predict the remaining lifespan of the inter-coupler system and bogie components. Train simulations highlight critical failure points in inter-coupler components, prompting the need for improved material choices and stress distribution strategies. Predictive maintenance, guided by stress analysis data, helps engineers take corrective action before failures occur, thereby enhancing rail safety and long-term reliability. Virtual stress tracking within simulation models reduces unforeseen failures and maintenance downtime.

- Braking System Optimization

Emergency braking is a critical safety measure for freight trains, especially when responding to unexpected obstacles or signal failures. However, the dynamics of emergency braking are complex due to the mass and momentum of long freight trains, which can lead to coupler failures or an extended braking distance.

SIMULIA Simpack enables detailed simulations of downhill speed control and emergency braking, accounting for wheel-rail interactions, brake force distribution, and train composition. Good braking performance is crucial for both safety and operational efficiency. And, did you know that different braking systems (i.e., disc brakes and regenerative brakes) can be compared to determine an optimal braking strategy that minimizes braking distance and wheel damage? The multibody simulation incorporates braking forces either as time-dependent excitations or as outputs of a control system, such as an anti-lock brake system (ABS), to assess safety and efficiency. Scenario models can predict the dynamic braking force distribution on the rolling stock, preventing large compression forces on inter-couplers and help determine the best train set arrangement.

- Virtual Certification

Traditionally, railway vehicles undergo extensive physical testing to meet certification requirements. Virtual certification, powered by MBS tools like SIMULIA Simpack, revolutionizes this process by enabling a significant portion of testing to be conducted virtually. This approach reduces costs, accelerates certification, and allows engineers to address potential issues early in the design phase. By adhering to standards like EN 14363 and EN 15839, virtual certification ensures compliance while streamlining the certification process. It also enhances safety and performance, making it an indispensable tool for modern rail freight operations.

How SIMULIA Simpack MBS Software Delivers Value to Railway Operators

Rail freight vehicle dynamics simulation using SIMULIA Simpack optimizes railway system performance by addressing derailment risks, optimizing emergency braking systems and ensuring safe speed limits are maintained. These advanced workflows enhance safety, reliability and efficiency, resulting in more resilient railway networks. These dynamic simulations, along with reducing the number of physical trials, can further reduce operator costs by enabling predictive maintenance, resulting in millions of dollars in repairs and downtime savings.

Combined with virtual certification, they represent a proactive approach to rail safety, ensuring compliance with stringent regulatory standards while reducing costs and improving operational performance.

For more information, please see these media content links on our website:

- Rail Vehicle Dynamics Video on YouTube

https://www.youtube.com/watch?v=nspPdHT0F4I - Transportation & Mobility, Trains webpage

https://www.3ds.com/industries/transportation-mobility/trains - Rail Simulation: Efficient Freight Operations Unveiled

https://www.3ds.com/industries/business-services/rail-freight-simulation - Rail Vehicle Dynamics Simulation

https://www.3ds.com/products/simulia/multibody-system-dynamics-motion-simulation/rail-vehicle

Interested in the latest in simulation? Looking for advice and best practices? Want to discuss simulation with fellow users and Dassault Systèmes experts? The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.