The Challenge of a Siloed Design Process

Traditional models separate designers and aerodynamics specialists into independent workflows. Design teams develop concepts and submit them to analysis teams for evaluation and review. This process creates significant technical bottlenecks.

Time delays represent the primary constraint. Designers wait one to two weeks for feedback on their work. This extended feedback loop reduces the efficiency of design iterations. When aerodynamic analysis is complete, design teams have progressed beyond initial concepts, making it difficult to make modifications without disrupting project schedules.

Collaboration presents another technical challenge. Disconnected tools and processes make information sharing discrete and cumbersome. This leads to specification inaccuracies and requires cascading modifications to vehicle body components to meet aerodynamic targets. This reactive methodology compromises original design intent and creates unexpected changes throughout development cycles.

A Unified Solution for Modern Vehicle Design

These challenges require solutions that are computationally efficient, accurate, flexible and unified. Designers need the capability to execute aerodynamic simulations independently, providing immediate feedback without dedicated analyst involvement. Results must maintain sufficient accuracy for informed decision-making. The system must handle various vehicle configurations and design explorations.

The 3DEXPERIENCE platform addresses these requirements through connected and streamlined workflows. It provides designers with expert-level computational tools in accessible interfaces. This allows treating aerodynamics as a unified design parameter rather than a final validation step. This approach enables efficient iterative processes conducive to design innovation.

Integrating aerodynamic analysis into early concept phases allows designers to begin from optimized positions. Initial concepts approach final aerodynamic targets more closely, reducing development time and minimizing subsequent modifications. This preserves critical design elements while allowing refinement time.

A Step-by-Step Workflow for Aerodynamic Integration

This process integrates computational tools within a unified dashboard. You move from sketches to thoroughly analyzed 3D models with significant speed improvements.

1. Modeling and Shaping: Begin in CATIA‘s Imagine & Shape and Natural Sketch applications. Create subdivision models and manipulate curves with intuitive controls. Parameterize these changes to enable rapid shape exploration through value adjustments.

2. Simulation Setup through Dashboard: Transfer ready designs into a dedicated dashboard through drag-and-drop operations. This dashboard automates complex Computational Fluid Dynamics (CFD) workflow steps.

- Model categorization: The system uses preset filters to automatically categorize assembly components—such as body panels and wheels—enabling the correct population of simulation templates.

- Mode build automation: CFD geometry preparation, known as meshing, traditionally requires manual processes taking days or weeks. The platform automates this using advanced algorithms that clean geometry, close gaps, and create simulation-ready meshes in approximately one hour for concept models. This converts manual work hours into automated machine time.

- Running the simulation: HPC enables running a CFD simulation in a matter of a few hours, with prepared meshes, build scenarios and submit for simulation. High-performance computing (HPC) enables the accurate calculation of aerodynamic results, including drag and lift coefficients.

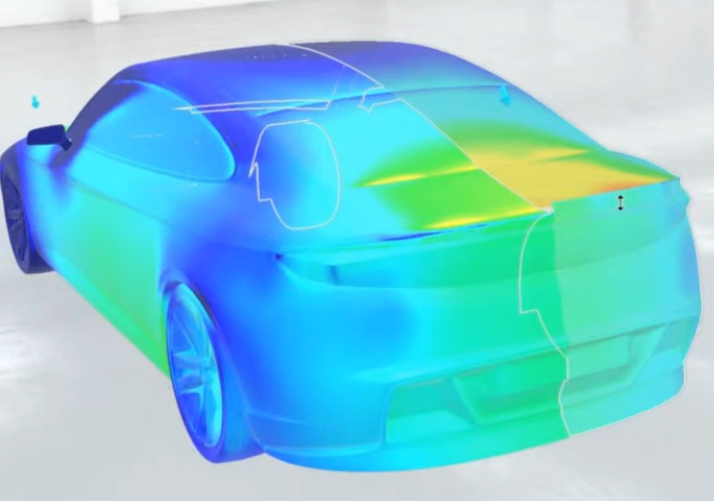

- Post-processing: Ability to access aerodynamics metrics such as drag and lift coefficients, but also preset flow visualization scenes, all in 3DEXPERIENCE in a matter of minutes. Multiple stakeholders can join to review results collaboratively.

Visualization and Collaboration in Virtual Reality

Understanding simulation data requires effective visualization capabilities. The platform provides advanced visualization tools, including immersive Virtual Reality (VR) through the Product Perception Experience application.

Loading simulation data for VR visualization requires only minutes. Multiple stakeholders can join shared virtual sessions to review results collaboratively. In this digital environment, visualize flow separation, pressure distributions and transient flow animations on 1:1 fully rendered scale models.

This collaborative environment enables real-time analysis and decision-making. For example, when teams determine that insufficient vehicle downforce or drag is present, designers return to modeling applications, adjust the rear spoiler geometry and save the changes as new revisions. (Note: This can be extended to any aerodynamic performance metric. Similarly, the rear spoiler geometry was an example of a design change, but other changes are possible.)

The dashboard flags outdated components. Replace with the latest revisions and rerun simulations, often reusing previous calculation components to reduce scenario preparation time. Compare the results from the baseline and modified iterations side by side. Analyze trade-offs—slight drag increases for desired downforce improvements—and evaluate target compliance.

The Future of Connected Design and Engineering

This streamlined modeling and simulation process integrates seamlessly within the broader 3DEXPERIENCE platform, connecting all aspects of product development. Requirements, project management, testing, and validation data are stored in unified repositories. This ensures that design studio decisions align with broader engineering and business objectives.

Integrating aerodynamics early and continuously enables automotive companies to accelerate innovation, reduce development costs, and create vehicles that balance design aesthetics with exceptional efficiency. This connected approach allows designers and engineers to optimize the balance between form and function, advancing vehicle development methodologies.

Interested in the latest in simulation? Looking for advice and best practices? Want to discuss simulation with fellow users and Dassault Systèmes experts? The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.