Challenge

Tetra Pak faced the complex challenge of making packaging more sustainable without sacrificing food safety, packaging strength, or manufacturing performance.

Solution

By adopting SIMULIA structural simulation technology, Abaqus for finite element analysis, Tetra Pak digitally modeled the sealing process, material behaviors, and equipment performance across diverse packaging formats. Using Abaqus’ advanced simulation capabilities, the team could virtually test new eco-friendly materials and packaging before building any physical prototypes.

Benefits

Simulation significantly reduced Tetra Pak’s development cycles, strengthened critical sealing performance, and validated new sustainable materials before they reach the factory floor, reducing waste and preventing production delays.

Inside Tetra Pak’s Quest for Sustainable Food Packaging

Global leader in food packaging advances safe, sustainable packaging by leveraging SIMULIA Abaqus technology to accelerate design and optimize sealing performance.

To consumers of packaged food, a carton or package is often regarded as an obstacle to consuming a meal. But at Tetra Pak, the world leader in food processing and packaging, every package is a crucial tool to get the food to your table while ensuring it remains safe and available globally. The Swedish multinational company is headquartered in Switzerland and spans 27 market companies, serving over 160 countries. It employs more than 24,000 people worldwide. The company motto, “Protects What’s Good,” reflects a mission to safeguard nutrition and reduce spoilage.

Tetra Pak Technology Specialist Per Karlsson notes that a significant share of global food production is squandered before it even reaches the people who need it. “Without the packaging, you couldn’t transport it, you couldn’t get it anywhere [without spoilage]. So in that sense, the actual packaging becomes important,” explains Tetra Pak Modeling & Simulation Development Engineer Karolina Wamsler. Tetra Pak cartons, especially its aseptic packages, keep food sterile and shelf-stable for up to a year without refrigeration, which can be a lifesaver in regions lacking cold storage. Now the company is striving for eco-smart packaging that maintains safety and maximizes longevity while minimizing environmental impact.

Packaging’s Sustainability Challenge

Achieving truly sustainable packaging involves solving a complex engineering puzzle. Tetra Pak must balance environmental goals, like using renewable or recycled materials, with the strict demands of food safety and industrial performance. Recycled paper or bioplastics, for instance, introduce uncertainties in traceability and hygiene that must be addressed before such materials can safely be used to store food. The new sustainable materials also behave differently during processing and have different requirements that, in some ways, are more challenging than the more conventional materials.

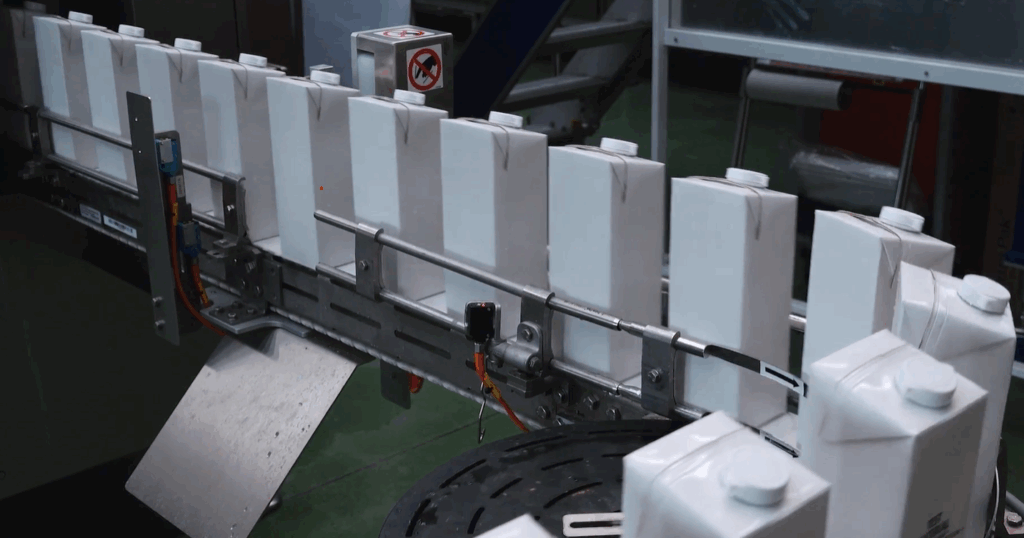

Packaging isn’t just the carton on the shelf; it’s the entire system that creates it. Tetra Pak designs custom filling machines that form, fill, seal, and cut packaging at staggering speeds. “Our fastest machine produces 40,000 packages per hour,” explains Wamsler, “and the components need to last for many years.” In other words, every packaging line must remain robust and reliable despite constant use and the variability of natural materials like paperboard (which differs by tree fiber or region). Customers around the world also demand different package sizes and shapes per local requirements, so one size rarely fits all.

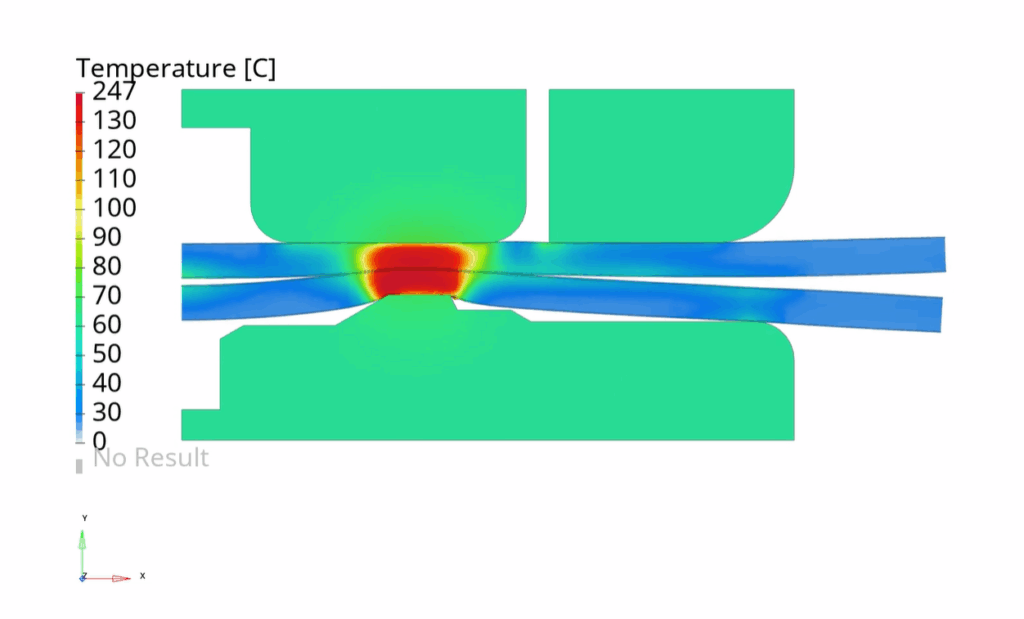

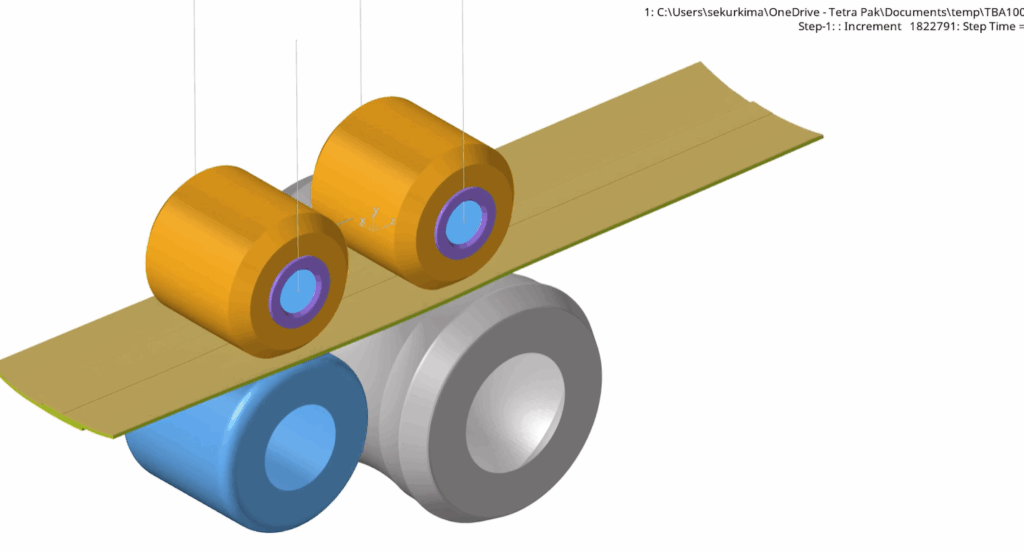

Simulating Every Aspect of Packaging Design

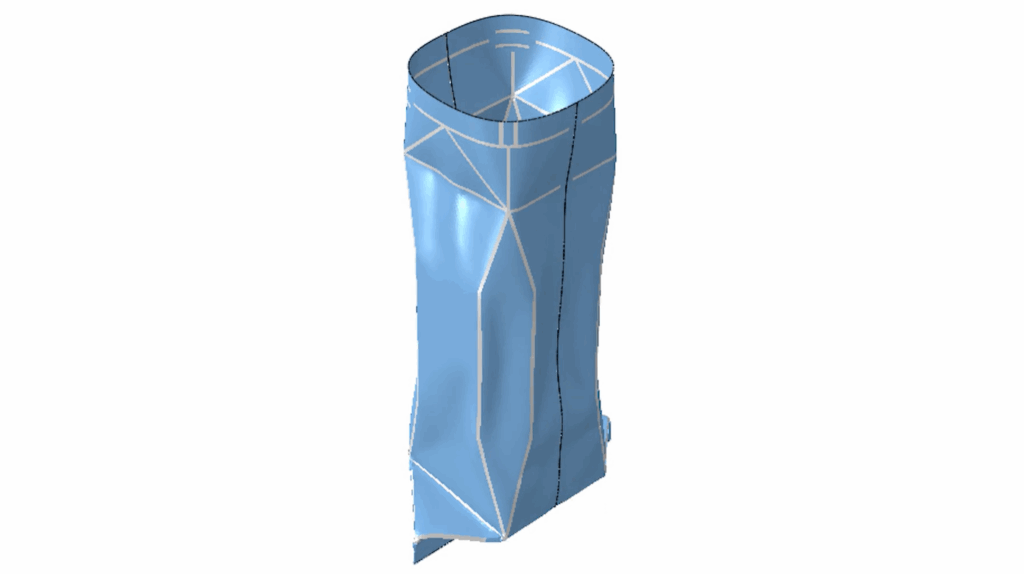

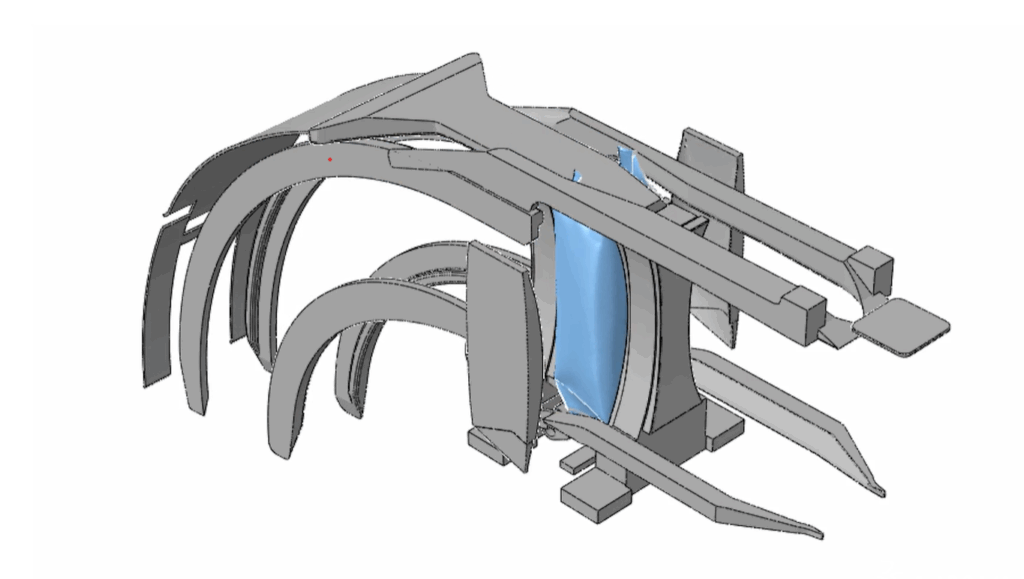

To help tackle these multifaceted problems, Tetra Pak turned to digital prototyping. The product development team utilizes several different disciplines of simulation to develop both the consumer package and the machine components. In Tetra Pak’s Sealing Technology department, Wamsler and Karlsson use SIMULIA Abaqus finite element analysis software to model everything from the stresses on machine parts to the heat and pressure of the sealing process. “Within the sealing department, we use simulation to look at all different aspects of development that include developing the components and how to seal with different materials,” says Wamsler. This means building multiphysics models that combine structural mechanics, thermal analysis, and even electromagnetics. For example, sealing some packages involves ultrasonic or induction heating, so engineers simulate electromagnetic fields alongside the resulting heat transfer and mechanical bonding of packaging layers. They also occasionally integrate computational fluid dynamics to examine how packaging material will interact with the liquid product during filling.

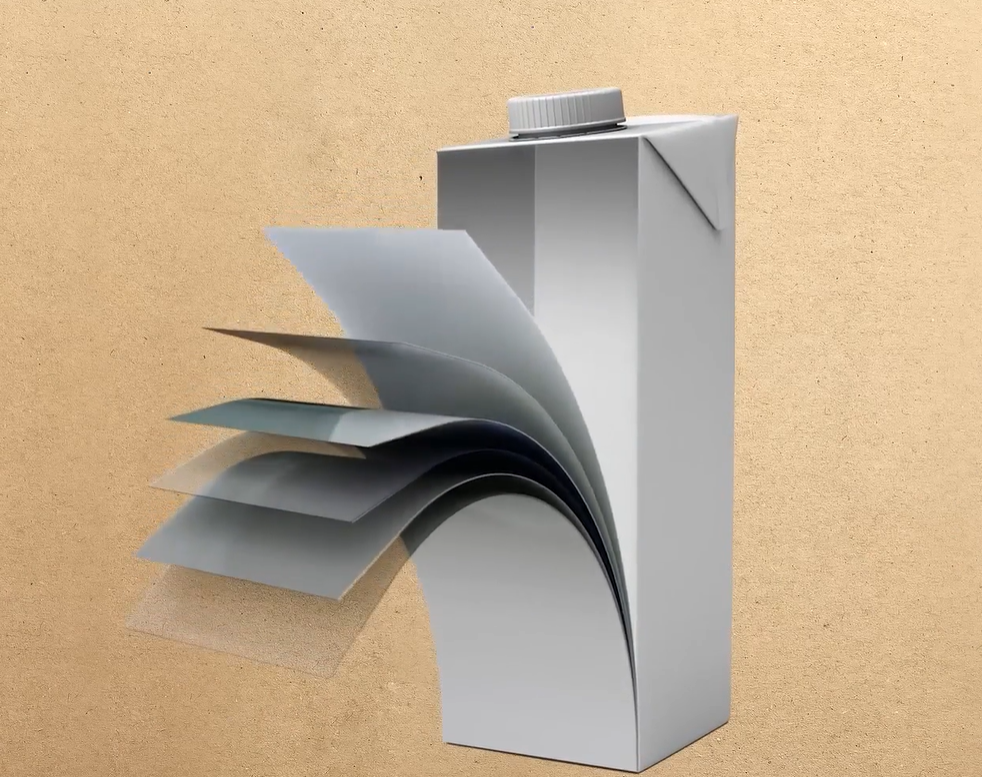

Tetra Pak engineers also must pay close attention to material behavior. A carton is made of layered paper, polymers, and sometimes aluminum—materials far more complex than uniform plastic. When introducing a new bio-based coating or a thinner paper grade, the team must ensure the seal will still hold and the package won’t tear. SIMULIA’s Abaqus provides a comprehensive library of material models, and for truly novel behaviors, the engineers write custom subroutine code. “For working with extremely complex materials, [Abaqus] has great flexibility in terms of subroutines,” Wamsler notes. This flexibility allows Tetra Pak to precisely simulate how a new polymer or paper blend responds to crimping, heating, or long-term loads—all in a digital environment. “We use Abaqus a lot throughout the entire company. It’s very robust and easy to work with,” she adds.

Simulation is more than isolated tests; it’s part of an iterative design strategy. Virtual prototypes empower Tetra Pak engineers to explore countless design variations quickly. “We can evaluate hundreds of different configurations and find the optimal design of our equipment,” says Karlsson. For a new package format or material, engineers adjust machine settings, sealing jaw shapes, or material thickness in the computer model rather than fabricating each change, which saves considerable time. For example, they can determine how a thinner packaging wall might affect seal strength, or how a modified sealing jaw might distribute pressure more evenly. This virtual testing is especially crucial when designing for sustainability.

Simulation with Abaqus enables finding an optimal solution that maintains machine throughput and seal integrity with greener materials. Karlsson emphasizes that such extensive exploration “basically wouldn’t be possible without the simulations. All the loops would take days, weeks … we have great help from simulation; we really speed up the loops.” Simulation with Abaqus allows Tetra Pak to innovate by design, not by expensive trial and error.

Rapid Results and a Greener Future

The payoff from this simulation-driven approach has been dramatic. Development cycles that once took months of building and breaking physical prototypes have been compressed significantly. “Working with simulations … you can get results really quickly, even before you have a [physical] prototype or anything,” Wamsler explains. “You can actually test out the idea and get an answer in an hour or a day. It really helps speed up the process.” This agility means Tetra Pak can respond faster to consumer demands and sustainability goals. For example, when experimenting with a new plant-based polymer coating, engineers can virtually validate that the existing sealing mechanism still works, or tweak the design if not, long before any real machine parts are made or material is produced. With simulation shortening each design loop, the engineering team is free to focus on refining ideas rather than debugging prototypes.

The quality of outcomes has improved as well. By digitally testing hundreds of scenarios, Tetra Pak finds better solutions than traditional methods yield. Packaging performance is enhanced: Seals are tighter and more reliable and machine components are optimized to avoid downtime even at high speeds. The Tetra Pak team notes that through simulation, they’ve achieved a comprehensive understanding of their packaging performance, enhancing efficiency and quality across a diverse range of products. And just as importantly, simulation enables innovation in sustainability. Tetra Pak can introduce eco-friendlier materials and, with Abaqus, quickly resolve any issues those new materials pose, from seal integrity to machine wear. The result is steady improvement in greener packaging without compromising safety or efficiency. Advanced simulation has become a key aspect of making packaging more resource-efficient and thereby helping make food available throughout the world through sustainable means.

Ultimately, Tetra Pak demonstrates that embracing simulation transforms an engineering challenge into innovation. What began as a delicate balancing act between protecting food and protecting the planet became a win–win: safer products, faster development, and a smaller environmental footprint. By virtually pushing materials and designs to their limits, Tetra Pak’s engineers are confidently creating the next generation of sustainable packaging solutions. Every food package reflects a wealth of unseen digital experimentation driving tangible progress in sustaining the planet.

Interested in the latest in simulation? Looking for advice and best practices? Want to discuss simulation with fellow users and Dassault Systèmes experts? The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.