Introduction

e-NVH is a critical consideration in the development of electric drives. The interaction of magnetic forces with structural and acoustic dynamics often generates unwanted noise and vibration, complicating design optimization. Manatee addresses this complexity by providing engineers with a dedicated environment for analyzing and mitigating these challenges.

This blog explores Manatee’s capabilities, outlining step-by-step workflows and highlighting advanced techniques for improving electric machine NVH performance. With Manatee’s multidisciplinary approach, engineers can identify key noise sources, refine machine designs, and implement effective solutions early in the development process.

A Demonstration of Manatee

In the Manatee environment, various features and tools allow you to define and analyze your electrical machine. Here’s a step-by-step overview of how it works:

- Defining the Electrical Machine: Manatee provides an environment to define your electrical machine. You have access to a magnetic material library and a multiphysics library that allows you to specify parameters like Young’s modulus for mechanical models.

- Exploring Different Topologies: Manatee supports various machine topologies, including induction machines, externally excited synchronous machines, outer rotor machines, and surface or interior permanent magnet synchronous machines. You can select the appropriate topology for your design.

- Step-by-Step Simulation Definition: Once you have defined your electrical machine, you can define your simulation. Manatee allows you to introduce tolerances and faults into the simulation, providing a comprehensive analysis of machine behavior.

- Running the Simulation: You can run it to generate the desired results after defining the simulation. Manatee offers powerful analysis tools to help you understand the noise sources and their impact on your design.

- Noise Solution Environments: Manatee provides specific noise solution environments tailored to different scenarios. You can also access generic parameter sweeps and optimization environments to refine your design further.

Manatee Workflow Example

For a practical example, consider the analysis of a 48-slot, 8-pole permanent magnet synchronous machine. The workflow is as follows:

- Define the Machine: Input the magnetic circuit geometry and material properties of your 48-slot, 8-pole permanent magnet synchronous machine.

- Set Simulation Parameters: Manatee offers predefined workflows. Select the “current-driven variable speed simulation” workflow.

- Customize the Workflow: Review and adjust the default models if needed. Specify whether you want to simulate a single speed or variable speed.

- Run Simulations: Execute the simulation to generate NVH data.

- Analyze the Results: Use Manatee’s built-in tools to analyze spectrograms and vibration data to identify noise sources.

- Optimize the Design: Make adjustments to your design based on the analysis to meet NVH targets.

This workflow allows you to assess and mitigate the noise and vibration levels of your electrical machine design, even in the early stages of development.

Stepping through a Current Driven Workflow

Let us explore a current-driven workflow vital in designing electrical machines to achieve specific torque requirements. One crucial strategy is the maximum torque per amp strategy, where Id and Iq currents as a function of speed have been optimized to reach the target torque. By selecting the simulation, you can gain an overview of the workflow, distinguishing it as a current-driven workflow rather than a voltage-driven one. You will find entry points within the specified range where Manatee requires additional data to perform the final calculation.

To ensure the accuracy of the calculation, it is essential to import the variable speed, Id, and Iq currents as they align with the workflow. Defining the speed range, typically from 500 to 8,000 revolutions per minute, allows for precise capturing of resonances resulting from the interaction between exciting forces and structural modes. The magnetic lookup table is a fundamental component for Manatee’s electromagnetic calculation. Manatee optimizes the number of magnetic calculations and employs clever interpolation techniques to reduce computation time. By validating and saving the settings, you can confirm the selection of torque-speed curve points for calculation.

Manatee uses a basic mechanical model of the stator stack model at the concept design phase by constructing an equivalent cylindrical shell or a beam element model. This approach offers insight into the characteristics of the naked wound lamination, allowing electrical engineers to optimize sound power levels during the early design stage. Running the calculation within Manatee builds the magnetic lookup table, reducing the number of magnetic calculations from 100 to 16 while accounting for nonlinear magnetostatic factors and different rotor positions.

As a result, Manatee calculates the Maxwell stress, exciting forces at the stator tooth tips, and forces on the rotor side. These calculations and the excitation of the model basis provide valuable information for evaluating and refining the model basis without significant increases in computation time. Subsequently, the sound level at variable speed can be calculated to assess and optimize the overall acoustic performance.

How to Define an Electrical Machine in Manatee?

Let us take a step-by-step approach to effectively define an electrical machine in Manatee. Here’s a breakdown of the key steps involved in a Permanent magnet synchronous machine:

- Define Lamination Dimensions and Slot Types:

- Use parametric templates for slot geometry.

- Import a user-defined geometry using a DXF file for more complex designs.

- Define the stator Winding:

- Utilize the automated method to define the winding based on the number of slots using the star slot method.

- This feature simplifies the process and ensures accuracy.

- Define the rotor Magnets:

- For magnet holes or magnet pockets, use predefined templates.

- Import a user-defined geometry for more intricate designs, allowing for complex flux bias configurations.

- Repeat the same for complex magnet layouts involving different magnet layers or different North / South poles

- Define Rotor Skew:

- Set the rotor skew using templated skew shapes or user-defined shapes.

Results of the Simulation

Manatee automatically plots the most relevant results once the calculation is complete (typically in a few minutes). Key outputs include sound as a function of speed, typically represented as a spectrogram. This visualization allows engineers to listen to the machine’s sound directly.

Manatee demonstrates the process from the input currents to the final sound power level. Engineers can trace the steps from the current-driven workflow to the resulting noise and vibration characteristics. The spectrogram provides a clear and detailed representation, enabling engineers to identify and analyze specific frequency components and their impact on the machine’s performance.

Evaluating the Resonances

Next, we focus on identifying and evaluating the resonances within the system. Through detailed analysis, we can observe the levels of each order in a comprehensive graph. For instance, the harmonic H 48 indicates a resonance occurring twelve times the electrical frequency in this specific electrical machine. This resonance is produced by a radial force applied to the stator, with a wave number of zero.

Manatee’s advanced algorithms allow us to determine the shape and exciting force driving the noise level at this particular resonance. Examining the radial force in the operational forces section and selecting the corresponding operating points allows us to visualize the pulsating force that excites the stator stack. This visualization enables further analysis and investigation of the system’s behavior.

Notching as a Remedy

The force at H 48 is particularly significant because it matches the number of slots in the machine. Several methods exist to address this exciting force, but one practical approach is notching.

Notching involves modifying the magnetic circuit by removing specific parts of it. This can be done on either the stator side or the rotor side. You can activate notching patterns to alter the magnetic field distribution on the stator side. Similarly, notching can be applied to the rotor side.

In this project, a notch has been implemented on the rotor side. This modification is straightforward to apply and optimize. Introducing the notch can reduce the impact of the H 48 harmonic, thereby mitigating the resonance and lowering the noise level. The notching pattern can be fine-tuned to achieve the best results, improving the machine’s performance while minimizing noise and vibration.

Using Parameter Sweeps in Manatee

Activating Notch and Setting Up Parameter Sweeps

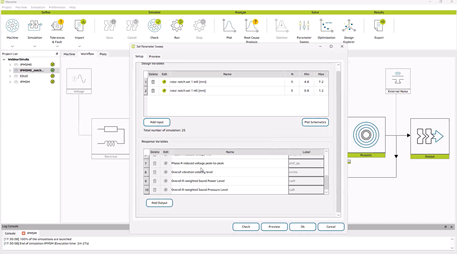

We activated the notch and defined a parameter sweep on the shape. Manatee makes it very easy to set up these parameter sweeps. Once you activate the parameter sweep, you gain access to all the inputs, including critical dimensions of the magnetic circuit, winding parameters, notch parameters, eccentricity, air gap, and even control settings.

With this parameter sweep, Manatee automatically selects the most interesting NVH (Noise, Vibration, and Harshness) metrics, such as sound power level and vibration, and electromagnetic metrics like torque ripple. You don’t need to set these up manually, but you can also define more advanced metrics if needed.

Example of Parameter Sweep Impact

In this project, we started with a reference simulation with a sound power level of around 90 decibels. After running a simple parameter sweep that took only five minutes, we reduced the sound power level to 83 decibels. This reduction of 7 decibels was achieved without significantly altering the rotor stress or disturbing the torque, effectively mitigating the key resonance caused by the magnetic excitation.

Transitioning to Electric Drive Unit Level

Now, let’s look at another way to use Manatee, focusing on the electric drive unit’s overall sound and vibration levels. We’ll use the same machine, like the Toyota Prius, and follow a similar workflow with a few modifications.

1. Variable Speed Current:

- We will use the same variable speed current.

- As an NVH engineer, we will ask the control engineers for the latest current angles from MTPA (Maximum Torque Per Amperes) and input these operating points into the simulation.

2. Magnetic Lookup Table:

- We will request the magnetic team to provide a pre-computed magnetic lookup table. The one calculated in the previous simulation can be re-used as we only change the structural mechanical model in this new simulation.

- This table is imported directly into the simulation, saving time and reducing the risk of errors due to the standardized interface.

3. Model Basis:

- We will ask the mechanical engineer to prepare a model basis for the actual powertrain, including the housing, gears, and other components.

- This model basis can be pretty complex, with around 300 modes, but Manatee filters and displays only the most relevant ones for e-NVH analysis.

4. Running the Simulation:

- After setting up the inputs, we run the simulation.

- The calculations can be completed in a few minutes on a laptop.

Analyzing the Results

Once the simulation is complete, Manatee provides a range of tools to understand the root cause of the sound and vibration issues:

1. Sound and Vibration Metrics:

- We can generate and listen to the sound of the new simulation, which is now at the electric drive unit level.

- Manatee allows you to identify which type of force is responsible for different resonances. For example, torque ripple on the stator side is responsible for a new peak at low speed when accounting for the more complex powertrain modal basis.

2. Frequency Axis and Mode Analysis:

- You can explore the frequency axis and display the modes to understand where the resonances are coming from.

- For instance, the above-mentioned resonance excited torque ripple on the stator side is a torsional mode of the stator.

Tools for Root Cause Analysis and Mitigation

Manatee offers a variety of tools for root cause analysis and mitigation:

- Predefined Workflows:

- Manatee provides predefined workflows that allow you to run adapted e-NVH calculations with just one click, depending on the design phase.

- Fast and Accurate Calculations:

- The calculations are based on finite element analysis ensuring speed and accuracy.

- Introducing Tolerances:

- Manatee allows you to introduce tolerances for robust design, such as eccentricities and magnetization variations.

- Mitigation Techniques:

- Manatee includes more than 15 mitigation techniques accessible to electrical engineers.

- These techniques include changing the magnetic layout, skew pattern, slot opening, notching on the stator or rotor side, and injecting harmonic currents.

Example of Mitigation Techniques

- Harmonic Current Injection:

- This technique involves introducing a small harmonic current to produce a small force that damps the force responsible for noise.

- It doesn’t increase joule losses because the RMS current remains unchanged, thus not altering the electromagnetic design.

- Notching:

- As we’ve seen, notching can be applied without disturbing the electromagnetic design, effectively reducing noise and vibration.

- By using these tools, Manatee helps engineers understand and mitigate NVH issues without redoing extensive mechanical stress analysis or efficiency calculations, making the design process more efficient and effective.

Licensing and Support

In terms of licensing, we offer a standard model with yearly subscriptions for both floating and node-locked licenses. One key feature is that all these licenses can be used in batch mode, meaning that if you have personal or optimization scripts and need to call Manatee for e-NVH calculations, you can do so seamlessly.

We also have a special option for High-Performance Computing (HPC) environments. To help you evaluate Manatee, we provide free evaluation licenses.

Additionally, we offer a unique service called e-NVH coaching hours. These are separate from the software and provided by our experienced e-NVH engineers. These engineers have been involved in numerous projects where they have identified noise problems and developed effective solutions. By availing yourself of these coaching hours, you can benefit from their extensive experience and insights, ensuring you get the most out of Manatee in your specific applications.

Frequently Asked Questions (FAQs):

Q1: Can we include magnetostriction in Manatee?

- Magnetostriction relates to magnetic noise and is considered negligible compared to Maxwell forces in Manatee. However, it is still an open research topic at specific frequencies. The consulting projects carried out by Manatee have been successful even without modeling magnetostriction.

Q2: Can we model unbalanced currents in Manatee?

- Unbalanced currents can cause e-NVH problems by breaking magnetic symmetry. Although it is an interesting fault to consider, Manatee does not directly support modeling unbalanced currents. However, this feature could be added if customer demand increases.

Q3: Do you intend to create a 3D environment?

- Integrating Manatee into a 3D environment, like the 3DExperience platform, is planned for the future. However, the official roadmap does not include this integration until 2026. Achieving seamless modeling from Catia to e-NVH requires substantial development.

Q4: How are the electromagnetic performances of the machine computed in Manatee?

- Manatee primarily uses 2.5D Finite Element Analysis (FEA) to compute the electromagnetic performances of electric machines. However, semi-analytic techniques like the Magnet Motive Force method and Circuit-Driven FEA are also used to balance accuracy and computation time for induction machines.

Conclusion

In conclusion, Manatee emerges as an essential tool for engineers tackling e-NVH challenges in electric drives. By providing a comprehensive suite of features for machine definition, simulation, and noise mitigation, it streamlines the design process and fosters early decision-making. With its advanced capabilities, Manatee not only enhances the performance of electric machines but also empowers engineers to effectively address noise and vibration issues, ultimately leading to quieter and more efficient powertrains.

We appreciate your attention and invite you to explore the SIMULIA User Community, where we have migrated a wealth of e-NVH learning materials. To gain a foundational understanding of NVH, we also recommend checking out our informative blog. For more information, check out our detailed webinar.

Interested in the latest in simulation? Looking for advice and best practices? Want to discuss simulation with fellow users and Dassault Systèmes experts? The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.