AI is transforming engineering by empowering engineers to be more creative and focus on high-value development. The rise of virtual twins and machine learning is shifting the role of simulation specialists, enabling them to create physics-based models that others can use to rapidly explore product performance within a design space. We spoke with SIMULIA CEO Michelle Ash to understand how AI and machine learning will reshape simulation, collaboration and the nature of engineering work.

How does AI enable more creative engineering?

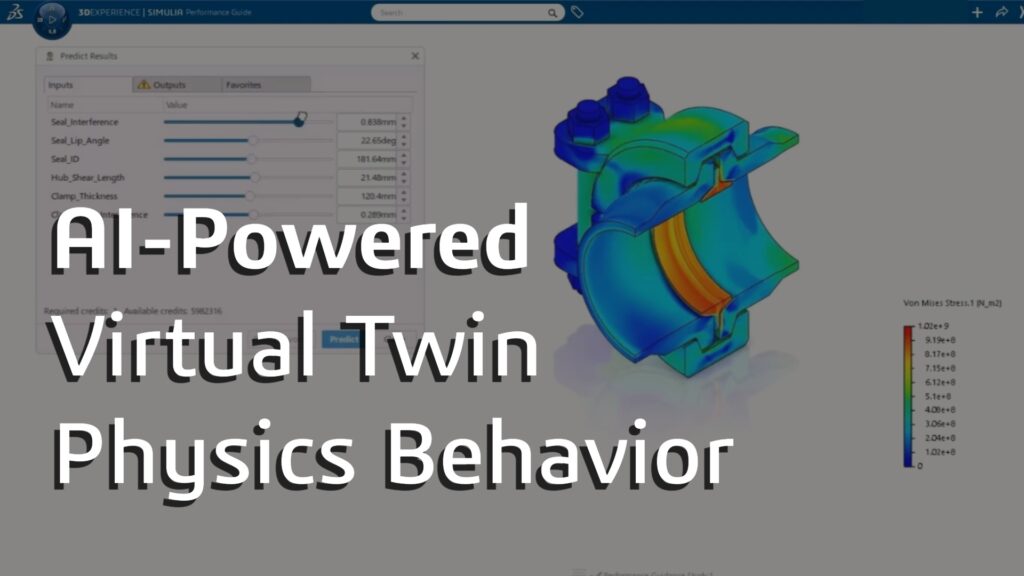

Michelle Ash: AI allows engineers to be more creative and perform more actual engineering. This happens thanks to virtual twins of physics behavior. Simulation specialists develop these physics behavior models by performing machine learning (ML) on a number of high-fidelity simulations covering a design space. The resulting physics behavior models can then be used by others to perform rapid design and performance studies. This shifts the simulation specialist’s role slightly; they still perform advanced simulation tasks, but their focus expands to include creating different models for others to use. Design and product engineers can then independently explore the design space, evaluate key performance indicators (KPIs), and visualize behavior in 3D, ultimately improving efficiency and fostering creativity.

How do AI and MODSIM work together?

Michelle Ash: MODSIM is the foundation of our AI/ML capabilities. MODSIM unifies modeling and simulation on a common data model within a single user experience on the 3DEXPERIENCE® platform. AI-enhanced MODSIM adds another layer of speed and intelligence. The Virtual Twins of Physics Behavior encapsulates and capitalizes the company’s best practices to evaluate a given design. As you change the design, you can quickly see the impact on product performance and other KPIs. This accelerates the process, reduces time spent in modeling and simulation task handoffs, and brings collaboration and approvals into a consistent framework, dramatically shortening design cycles.

What are the key data considerations when using AI at scale?

Michelle Ash: There are three primary considerations: quality, management and process.

The quality of data used to train AI models is paramount; good data in produces good information out.

Second, AI generates a massive amount of data. You need a pre-planned strategy for managing and storing this data, allowing for its retrieval. Setting these systems up correctly from the start is essential for leveraging the full capability of AI.

Finally, with MODSIM processes, you can embed requirements, design intent, and even your thought process directly into the design itself. This allows you to easily capture and replicate your design and simulation methods. MODSIM unifies the data model behind CAD and CAE, eliminating the need to export or convert models for simulations. This seamless integration ensures traceability, eliminates the delays, data loss, and frustration associated with passing datasets between different people and software. Instead of a linear, disconnected process, you have a fluid workflow where changes can be made and tested much more efficiently.

What are the biggest challenges in adopting AI for engineering today?

Michelle Ash: We are in the early days of applying AI and machine learning to 3D modeling and simulation this way. This can be nerve-wracking for engineers who rely on known, consistent processes. Adopting AI requires exploring new workflows and building trust while disrupting methods that may have been used for decades. There is a challenge in trying new things, but it will enable a better and more efficient way forward.

What is your long-term vision for AI in engineering?

Michelle Ash: My vision is to bring engineering to everybody. Many people want to understand how the world works, but lack the mathematical or scientific skills. When trained on trusted physics simulations, AI can provide real answers to engineering questions, from why it’s best to bend your knees when picking up a heavy object to what happens if you modify a car part. We can use AI to democratize access to physics-based knowledge.

What can customers expect from this technology, both now and in the future?

Michelle Ash: Out of the box, you can expect a tool that applies to your use cases to demonstrate value. We will work together to develop additional features that address your specific needs. In the longer term, you can expect less repetitive work, more innovative work, and frankly, more fun in your job.

What is the ultimate promise of AI for the engineering profession?

Michelle Ash: The promise is a future with more efficient workflows, more efficient industries, and more exciting jobs. By embracing exploration and innovation together, we can reduce tedious tasks and free up simulation specialists to focus on what they do best: creating and solving problems. This won’t only improve our work but also make our industries more competitive.

Key Takeaways

- Creative Empowerment: AI enables engineers to focus on creative development by automating repetitive design tasks through virtual twins of physics behavior created with machine learning based on high-fidelity physics data.

- Well-defined Scope is Crucial: Thoughtfully defined limits are essential to guide AI in simulations, ensuring it explores valid design spaces and produces usable outcomes.

- Data Strategy is Fundamental: The success of AI in engineering hinges on high-quality training data and a robust, pre-planned strategy for data management.

- MODSIM + AI = Fast Innovation: Combining unified modeling and simulation (MODSIM) with AI enables fast design exploration, collapsing traditional development cycles.

- A More Fulfilling Future: The long-term impact of AI will be a shift away from repetitive tasks, leading to more efficient industries and more creative, innovative and engaging work for engineers.

Interested in the latest in simulation? Looking for advice and best practices? Want to discuss simulation with fellow users and Dassault Systèmes experts? The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.