The automotive industry is at a historical inflection point. Many OEMs have adopted a long-term EV strategy, but wide-scale market adoption remains uncertain. Now more than ever, OEMs require an agile product development platform to respond quickly to shifting EV strategies and market demands.

To stay competitive in a changing market, many OEMs must consider using different materials to reduce noise and improve customer comfort.

Ford, a leading automotive manufacturer, confronts the dual challenges of vehicle electrification and light-weighting. The shift to electric vehicles (EVs) eliminates engine masking noise, accentuating other sounds like squeaks and rattles. Concurrently, the use of lighter materials like aluminum to improve efficiency makes vehicles more susceptible to noise and vibration. Ford required a robust method to analyze and optimize components for noise, vibration, and harshness (NVH), durability, and comfort.

Solution:

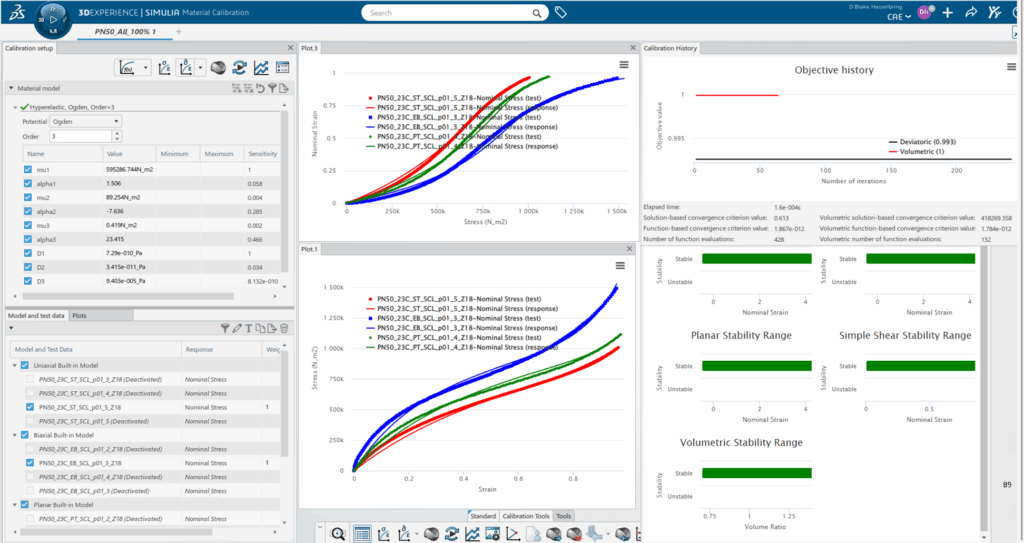

By implementing SIMULIA solutions on the 3DEXPERIENCE platform, including the Material Calibration App, Ford developed a comprehensive material library. This enabled efficient analysis and optimization of rubber components, ensuring vehicle quality and comfort while accelerating the design process.

Benefit/Result:

Ford’s creation of a centralized material library allowed it to standardize the properties of various materials, ensuring that data was not only accessible but also accurate. Engineers could now use a reliable source of information for simulations and analyses, significantly reducing the time spent searching for material properties.

The Challenge: Navigating New NVH Frontiers in Automotive Design

The automotive industry is undergoing a significant transformation. The rise of EVs introduces new complexities for NVH engineering. Without the sound of an internal combustion engine, other noises become more prominent to the customer. This requires engineers to pay closer attention to squeaks, rattles, and component isolation.

“The automotive industry is very competitive. If you’re not the toughest and the quietest and the most durable out there, you’re going to face some challenges.”

— James Swayze, Senior Technical Specialist in NVH, Ford Motor Company

Simultaneously, the push for greater efficiency has led to light-weighting across vehicle platforms. While materials like aluminum reduce overall mass, they also present NVH challenges. Lighter, less dense materials are less effective at blocking sound. This trend, combined with the increased weight of battery electric vehicles (often 6,000-7,000 pounds compared to a traditional car’s 4,000 pounds), creates a more complicated engineering environment. Engineers must manage these conflicting demands to deliver a quiet, comfortable, and durable vehicle.

Ford needed a way to accurately predict the performance of isolation components, optimize parts within tight package space constraints, manage a wide range of materials to meet strict durability and performance targets and accelerate the analysis cycle to maintain a competitive edge.

The Solution: A Data-Driven Approach with SIMULIA

Ford adopted SIMULIA solutions on the 3DEXPERIENCE platform to build a sophisticated material analysis and simulation workflow. A key component was the development of a detailed material library for rubber components, a critical element in vehicle isolation and damping.

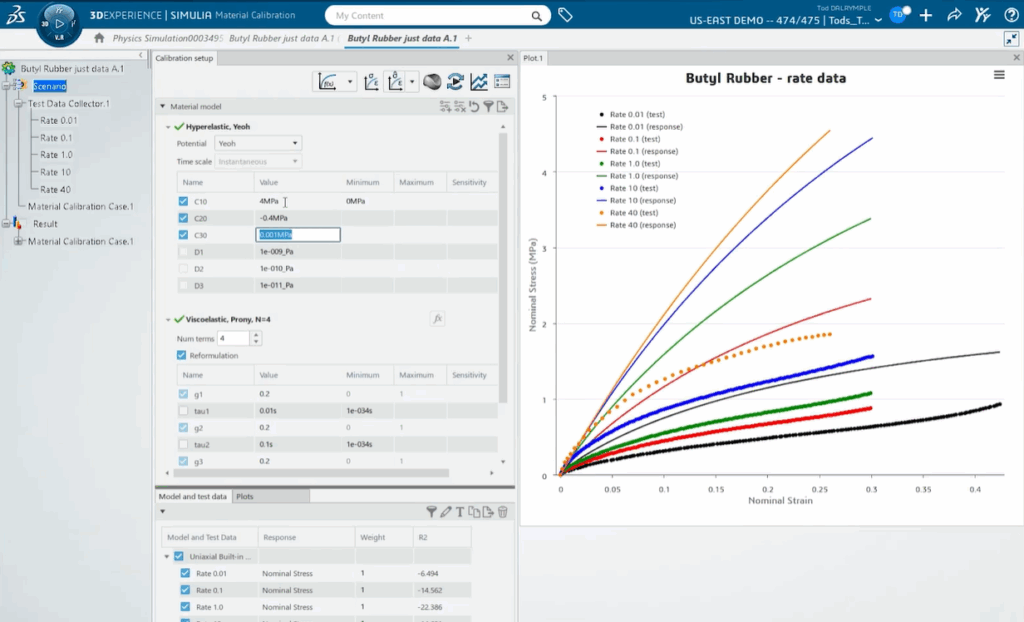

The SIMULIA Material Calibration App was instrumental in this process. It provided Ford’s engineers with a simple, fast, and accurate tool to process material test data. The app allowed them to quickly calibrate complex material models, such as the Prony series for modeling the Payne effect in rubber.

“The Material Calibration App is really simple to use… it’s very quick. Once we got our data, [it was] very quickly processed and it’s very accurate. When you do the iterations to fit the data, it’s spot on every time.”

— James Swayze, Senior Technical Specialist in NVH, Ford Motor Company

Using the calibrated material data, Ford leveraged the integrated suite of SIMULIA tools to build and analyze Finite Element Analysis (FEA) models. The platform’s parametric design capabilities allowed engineers to run optimizations, adjusting a component’s size and shape to find the ideal balance of stiffness, durability, and isolation performance. This entire workflow from material testing to model creation, analysis, and optimization is seamlessly integrated on the 3DEXPERIENCE platform.

Results: Optimized Performance and Unprecedented Efficiency

By adopting SIMULIA solutions on the 3DEXPERIENCE platform, Ford’s NVH team has fundamentally changed the way they manage material analysis and design optimization. The creation of a centralized material database brought a new level of reliability and improved accuracy, giving engineers confidence in their simulation models.

One of the immediate improvements came from replacing time-consuming manual processes with the Material Calibration App. What previously required building custom solvers in Excel spreadsheets now takes only a few clicks, freeing up time to evaluate more materials and explore additional design iterations.

With parameterized models and powerful simulation analysis tools, Ford can now efficiently optimize components such as mounts and isolators for performance and packaging. This ensures adequate durability and isolation without consuming unnecessary space, which is a critical consideration in modern vehicle architecture.

Perhaps most importantly, the app’s ability to process test data and fit material models with high fidelity gives engineers confidence in their simulation results. This accuracy is crucial for meeting Ford’s tough durability standards and delivering a final product that meets customer expectations for comfort and quietness.

“Before we had the Material Calibration App… I used an Excel solver to do that. You have to build it and put all the data in… it takes a lot of time. With this, you just import the data and boom, it’s right there. So, very quick and easy.”

— James Swayze, Senior Technical Specialist in NVH, Ford Motor Company

Conclusion

As the automotive landscape evolves, the demands on engineering teams intensify. Ford’s experience demonstrates that a powerful, integrated simulation platform is essential for success. By leveraging SIMULIA on the 3DEXPERIENCE platform, Ford has empowered its engineers with the tools to tackle the complex NVH challenges of modern vehicles. The ability to quickly and accurately calibrate materials, simulate performance, and optimize designs allows Ford to remain a leader in producing durable, quiet, and high-quality vehicles in a competitive global market.

Interested in the latest in simulation? Looking for advice and best practices? Want to discuss simulation with fellow users and Dassault Systèmes experts? The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.