Stepping into the world of dairy farming often conjures images of vast green fields, grazing cows, and traditional barn structures. However, behind these pastoral scenes lies a complex, innovative industry dedicated to the welfare of dairy cows and efficient milk production. Based in Seneca Falls, NY, Seneca Dairy Systems stands at the forefront of this development. With a commitment to enhancing cow comfort and optimizing dairy farming operations, Seneca Dairy Systems combines modern engineering practices with a deep understanding of animal needs to create practical solutions for the dairy industry.

At the heart of Seneca Dairy’s operations is a team of skilled engineers and designers, including Ken Mansfield, a senior mechanical engineer, who plays a key role in developing equipment tailored explicitly for dairy facilities. Mansfield emphasizes the importance of their mission: “We design and manufacture equipment for dairy cow facilities, focusing on cow comfort and their housing and handling.” This commitment to improving animal welfare underscores the company’s ethos and sets the stage for innovative product development.

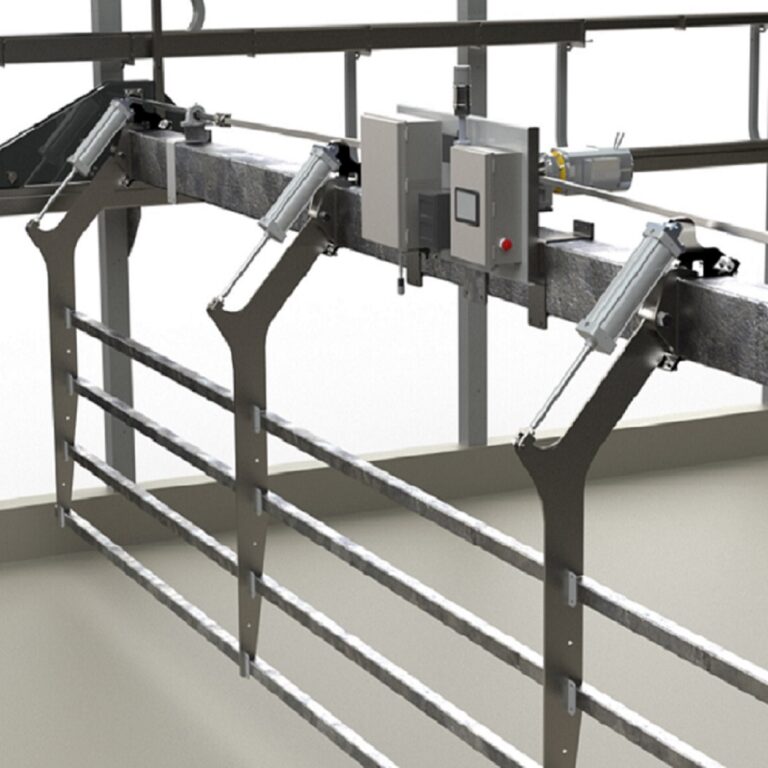

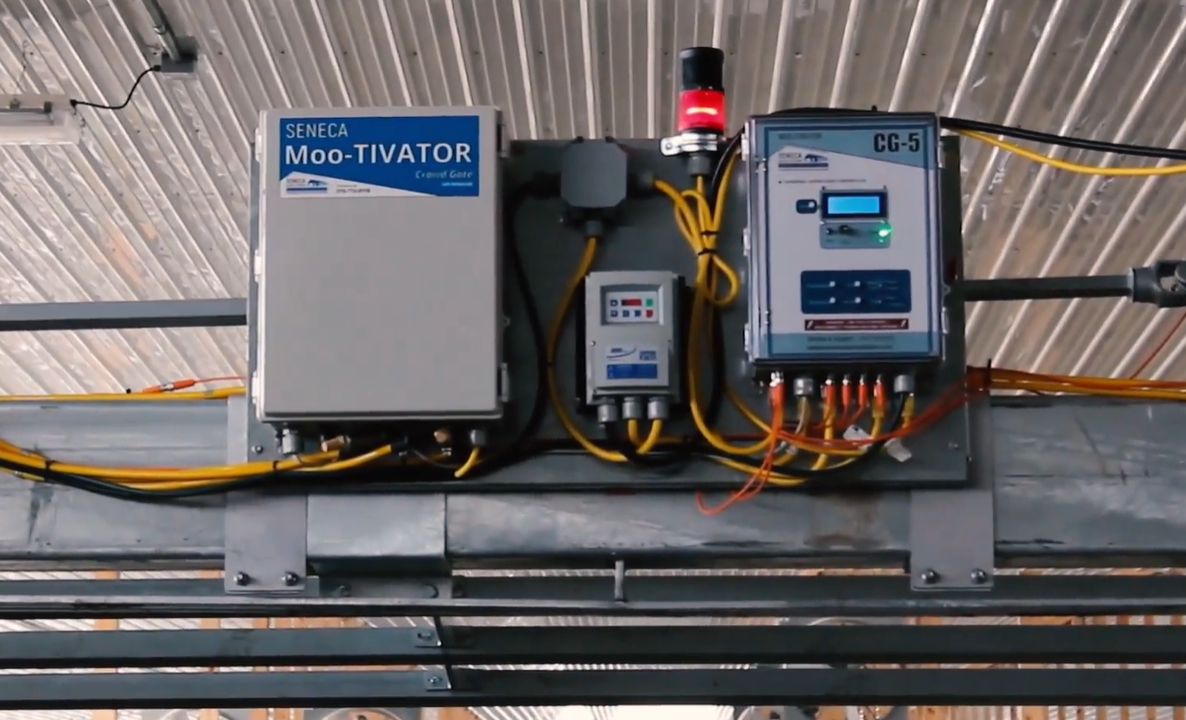

On one end of the spectrum, the company designs various types of gates that manage the movement of cows within a facility, like the Moo-TIVATOR Crowd Gate, an advanced system designed to take the hassle out of moving a herd into a parlor, combining the latest in safety and convenience. Mansfield remarks, “Some things are very simple and straightforward, like a gate, but there’s a dizzying array of variations that farmers need.” Each gate is tailored to specific needs, considering size, durability, and ease of use. This results in a wide range of customizable options that cater to the diverse requirements of different dairy operations.

On the more complex side of their offerings, the team designs milking parlors that address the intricate needs of dairy cows during milking time. These advanced systems require a thorough understanding of cow behavior and handling techniques. “Our designs account for the comfort and needs of both the cows and the human workers,” notes Mansfield. This thoughtful design process ensures efficiency and comfort during milking, showcasing the innovative engineering applied at Seneca Dairy Systems.

The design process at Seneca Dairy Systems is a blend of innovation and evolution. The engineering team often starts with legacy designs, modifying and improving them to better serve contemporary needs. “Part of our design process involves taking what we have and changing it, improving it,” explains Mansfield. This iterative approach allows for incorporating new insights and technologies, enhancing the effectiveness of existing products. For example, if a new clamp is required, the team reviews current models and adjusts based on user feedback. In addition to refining established products, Seneca Dairy Systems is deeply invested in new product development. Mansfield asserts, “Seneca is focused on being innovative and creating new solutions.” The commitment to innovation drives the team to create groundbreaking solutions from the ground up.

Often, the process begins organically with hand sketches or whiteboard designs, which are then transformed into detailed SOLIDWORKS models. This tool is favored for its intuitive design capabilities and powerful functionalities, allowing engineers to transition from concept to production seamlessly. “With SOLIDWORKS, we can take those ideas and turn them into a physical product smoothly,” he adds. SOLIDWORKS plays a critical role in turning these sketches into physical products. Its user-friendly interface enables the engineers to manipulate designs and configurations efficiently. “We have a lot of configurations; some of our products have numerous variations, especially the gates,” states Mansfield. These variations ensure that every product is customizable and meets specific needs, allowing for better efficiency in dairy operations.

Engineering Benefits

From Ken Mansfield’s 2025 3DEXPERIENCE World Presentation

- Tighter collaboration between stakeholders

- Optimized motion of gating mechanisms

- Improved strength of gating systems

- Unintuitive insights before prototyping

- More innovation with lesser IT costs

Beyond its immediate applications in design and manufacturing, the work done at Seneca Dairy Systems reflects a larger commitment to dairy farming’s sustainability and efficiency. The company enhances farm productivity by improving cow comfort and facilitating better handling practices. “Healthier and more comfortable cows not only lead to higher milk production but also foster a better ethical standard within the industry,” Mansfield explains. This connection between cow welfare and farm output highlights the importance of a compassionate approach to dairy farming.

Moreover, the emphasis on innovation resonates with the dairy industry’s broader challenges today. As consumers become increasingly concerned with animal welfare and environmental sustainability, companies like Seneca Dairy Systems are key in setting new standards. Mansfield states, “Our dedication to creating efficient, safe, and humane farming practices is essential for the future of dairy farming,” addressing current demands and future operations expectations.

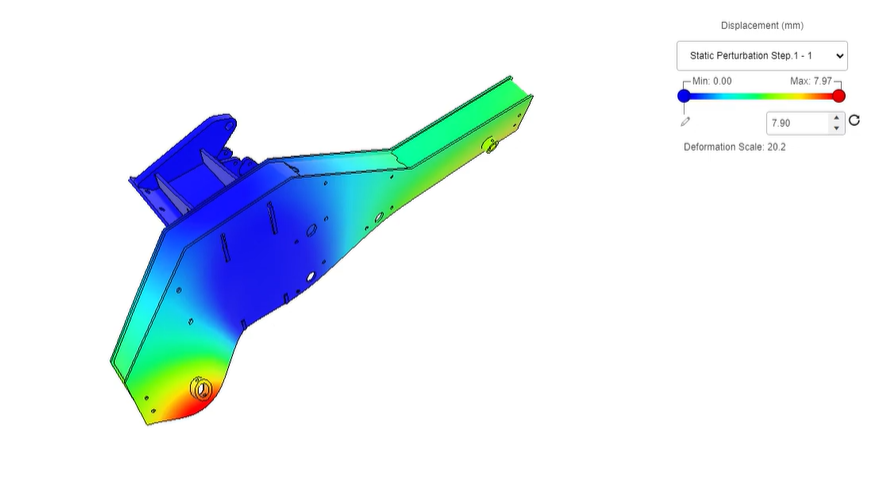

As a designer, Ken first adopted the SIMULIA Structural Designer role and quickly recognized its efficiency, providing exactly the tools he needed to run advanced simulations and obtain precise results. For the Moo-TIVATOR, certain parameters are challenging to measure without building a physical prototype, so the ability to test and refine these factors virtually is a major advantage.

Business Benefits

From Ken Mansfield’s 2025 3DEXPERIENCE World Presentation

- We can now build things we couldn’t before!!!

- More technologically complicated products

- Ramped up mass customization

- Physical testing is impractical as we don’t own a farm. Simulation addresses this challenge.

- Prototypes reduced, physical test passed the very first time, more engineering – less material

Through the collaboration of engineers, designers, and dairy farmers, Seneca Dairy Systems continually strives to revolutionize dairy production methods. The blend of tradition with innovation aims to honor age-old practices while tackling modern challenges. “It’s about finding that balance,” Mansfield concludes, signifying the ongoing journey toward improvement and advancement in dairy farming.

Ultimately, Seneca Dairy Systems’ story is one of dedication, innovation, and compassion. As the company continues to grow and evolve, its commitment to improving dairy practices will undoubtedly impact the industry, ensuring that farmers and cows thrive in an ever-changing landscape. By prioritizing cow comfort and embracing cutting-edge technology, the future of dairy farming looks brighter than ever, promising a harmonious balance between productivity and animal welfare.

Interested in the latest in simulation? Looking for advice and best practices? Want to discuss simulation with fellow users and Dassault Systèmes experts? The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.