Introduction

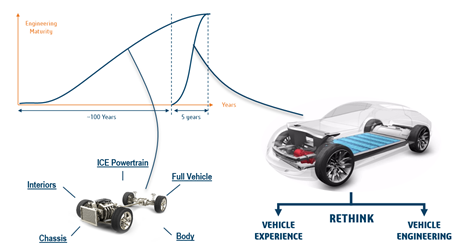

The leap toward vehicle electrification marks a significant evolution in automotive technology. Innovations in battery technology and advanced simulation are at the forefront of this transition, supporting reliable and high-performing EVs. Internal combustion engines (ICEs) have been critical players in vehicle power, delivering dependable performance and fuel efficiency for over a century. However, the accelerated evolution of electric vehicles (EVs) has become vital for addressing new performance and safety demands.

Building on the overview of electrification’s impact on vehicle engineering, the following section will explore the technological advancements driving this transition.

The Evolution of Vehicle Technologies

Internal combustion engines provided reliable performance and efficiency for decades, but EVs have redefined output and design flexibility benchmarks. In less than a decade, EVs have matched and surpassed their ICE counterparts’ power output and performance metrics in some aspects. This swift evolution has led to a growing demand for dependable solutions to tackle the challenges of new technologies in this field. Innovations in battery technology and advanced simulation tools are critical in addressing this transition’s new challenges.

Batteries are vital components in electric vehicles and are responsible for generating energy while ensuring safety. They are complex and require advanced engineering, from chemistry to full vehicle integration. This blog explores how simulation is used extensively on battery cells to improve performance, strength, stiffness, and safety, particularly in abuse scenarios.

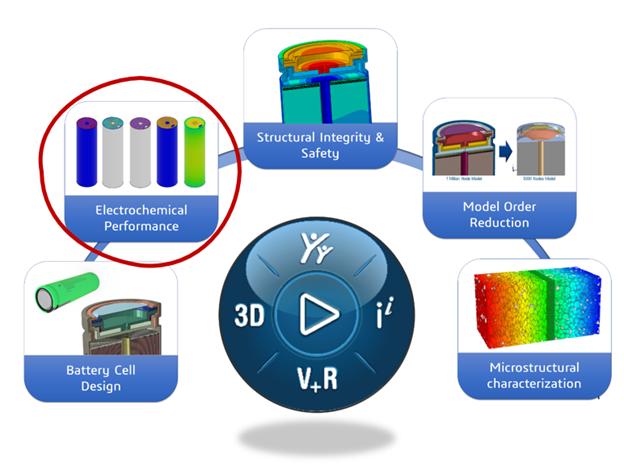

To tackle complex challenges through simulations, it’s essential to use advanced Finite Element Analysis (FEA) tools. Abaqus has long been a foundational tool from Dassault Systèmes for structural analysis, including complex non-linear problems. Over the past decade, the company has expanded its capabilities to include other physics disciplines such as Computational Fluid Dynamics (CFD) through PowerFLOW and Electromagnetic Field Simulation with CST Studio Suite.

All these technologies are integrated on a single platform: the 3DEXPERIENCE platform. The platform provides an innovative way to conduct battery cell engineering simulations, allowing for a seamless transition between different types of simulations. As a result, engineers can ensure that each component operates optimally within the overall system, enhancing the safety and efficiency of electric vehicles.

The advancements in EV technology bring unique challenges in battery design, requiring innovative approaches to address performance, safety, and integration.

Challenges and Considerations in Battery Technology

Battery Design & Management

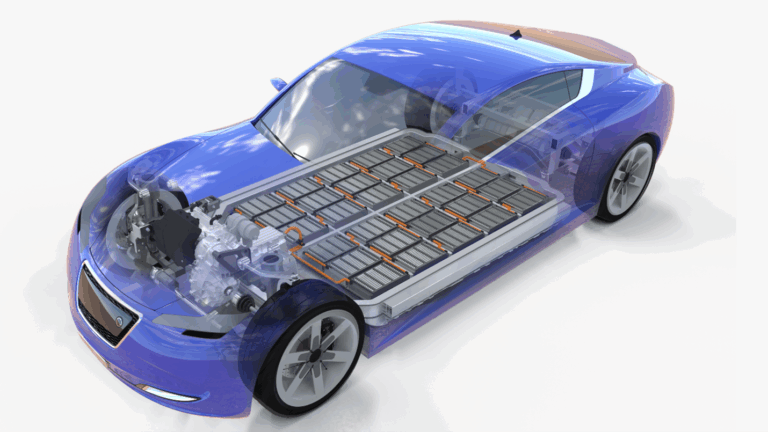

The EVs primarily involve the integration of three key components:

- The battery serves as the primary power source.

- The electric drive propels the vehicle.

- Power electronics manage the energy supply.

The comprehensive design process of these battery systems involves multiple critical aspects. Engineers must consider everything from the choice of materials and the configuration of battery cells to the integration of advanced cooling systems. For example, the system must maintain a temperature gradient of less than two degrees. This stringent requirement helps prevent overheating and ensures the battery operates within its ideal thermal range.

The battery’s ability to supply electrical power is critical, as it powers the electric drive and auxiliary systems within the vehicle, such as the Heating, Ventilation, and Air Conditioning system (HVAC). It must adapt to different voltage requirements while managing thermal loads, which can increase resistance and stress. Pre-manufacturing simulations are vital in identifying and mitigating potential failures, ensuring a robust and reliable battery system for EVs.

Unlike bulky internal combustion engines, batteries are placed differently within a vehicle, offering greater architectural flexibility. Typically placed on the car’s floor, they optimize space and shift the center of gravity. This leads to necessary adjustments in chassis design, especially since batteries are heavy and significantly affect weight distribution.

HVAC systems play a crucial role in ride comfort, drawing power from the battery. The energy demands of HVAC, depending on weather conditions, can affect the range and performance of electric vehicles. Therefore, it’s essential to consider battery efficiency and capacity carefully.

The integration of battery systems into vehicle architecture introduces additional design considerations, including weight distribution, structural adjustments, and thermal management.

Key Considerations in Vehicle Architecture

- Innovation in design: Innovative design approaches are necessary to meet the automotive industry’s needs. Companies vary in approach; some keep traditional structures while others innovate with new EV architectures.

- Design simulation: Diverse design strategies highlight simulation’s importance in evaluating different architectural options for their performance and suitability.

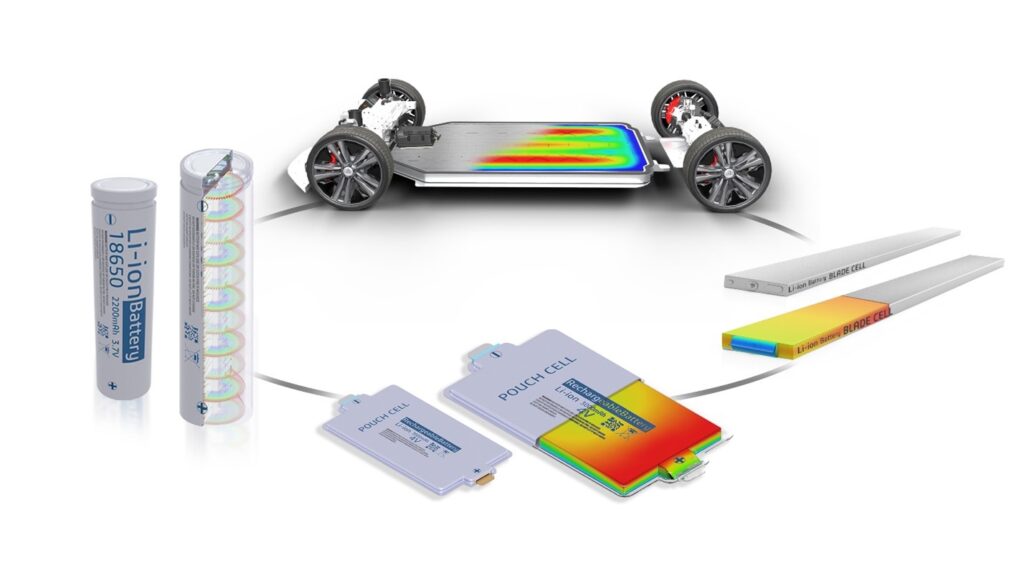

- Battery cell types: Automakers’ preference for cell types (cylindrical, pouch, prismatic) affects the design, placement, and manufacturability of battery modules and packs.

- Rapid simulation and analysis: Accelerated simulation workflows are critical in achieving faster data-driven improvements to vehicle design.

A structured engineering workflow, starting from material-level simulations to full vehicle integration, is essential to systematically address these challenges.

Battery Cell Engineering Workflow

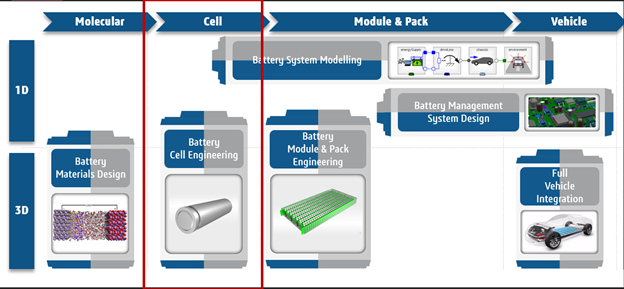

Dassault Systèmes offers technologies that enable the design and development of battery systems, starting from the molecular level and extending to full vehicle performance. Engineers can create and formulate materials for components such as anodes and cathodes at the molecular level using various chemical compositions. Our sister brand, BIOVIA, enhances this capability, facilitating molecular-level simulations.

The properties derived from these materials can then be applied in continuum-level simulations. This approach extends to simulations at the cell, module, and pack levels, optimizing battery systems’ design, performance, and efficiency. Different methodologies are employed at the battery cell level to tackle engineering challenges, which are carried through to the module and pack levels to provide comprehensive solutions.

1D simulations help evaluate battery systems’ performance regarding power or voltage requirements while also integrating battery management systems for effective thermal control. Tools like Dymola analyze overall system performance by performing 1D system-level simulations.

The Battery Management System (BMS) ensures optimal operation and longevity. It manages charging cycles, monitors the battery’s health, and provides safety through thermal management. Finally, the optimized battery design is integrated into the full vehicle model to identify and resolve non-battery-related issues.

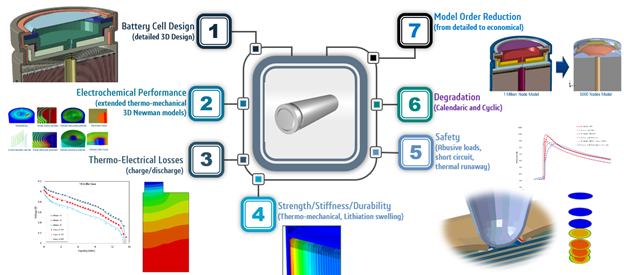

In this blog, we will focus on the key workflows for designing battery cells, which all fall under the umbrella of battery cell engineering.

The engineering workflow begins with the design and analysis of battery cells, focusing on safety, structural integrity, and performance under operational conditions.

1. Battery Cell Design, Analysis & Safety Considerations

Battery cells are primarily categorized into four types: button cells, prismatic cells, polymer or pouch cells, and cylindrical cells. Each type exhibits unique characteristics and thermal behavior.

To design an efficient battery cell, it is essential to consider appropriate operating condition effects like temperatures, ionic flow, voltage and current variation, abused structural loads, and the correct cell geometry. Dassault Systèmes has developed different workflows to help engineers validate and enhance battery cell performance under various conditions, addressing multiple physics streams like electrochemical, thermal, structural, etc. We will discuss a few of these methodologies in a later section.

Electrochemical performance analysis is a critical step in understanding the effects of charge-discharge cycles, thermal behavior, and material interactions within the cell.

2. Electrochemical Performance Analysis

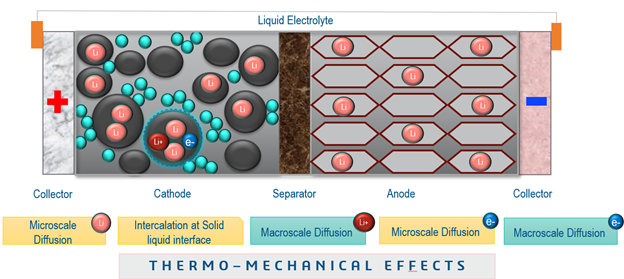

In battery cell engineering, analyzing electrochemical performance is crucial. The performance of a battery highly depends on the effects of repeated charging and discharging cycles, which can cause the degradation of the battery’s capacity over time. Detailed evaluations focusing on ion and electron movements within the cell, which impact temperature profiles, inform decisions regarding the placement of anodes, cathodes, and separators.

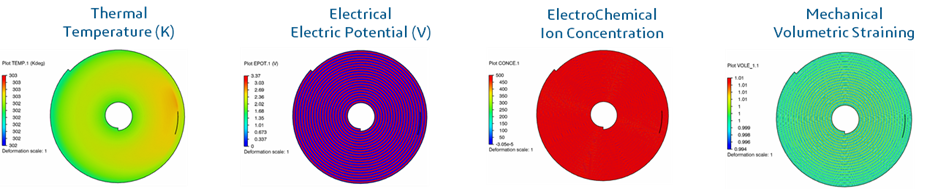

This analysis examines micro- and macro-scale diffusion, thermoelectrical losses, and charging and discharging effects. Electrochemical analysis can be performed using porous electrode theory (PET) in Abaqus/Standard, based on a homogenized Newman-type approach that simplifies the complex pore geometry.

At the macroscale, the porous electrode is modeled as a homogenized medium consisting of the superposition of an active solid electrode particle phase and a liquid electrolyte solution phase, with known volume fractions. At the microscale, a collection of spherical particles is assumed for which a (nonlinear) lithium-ion diffusion model is solved. A conductive binder connects the solid particles and together forms the solid electrode phase.

Due to their multiple advantages over other battery types, lithium-ion batteries have become the backbone of rechargeable batteries used in EVs. The electrochemical performance of these batteries depends on the interaction between various diffusion processes. During charging, lithium ions are intercalated through the electrolyte. At the same time, electrons flow through the external circuit, highlighting the duality of macro-scale diffusion for lithium ions and micro-scale diffusion for electrons. Conversely, during discharging, the processes reverse, underscoring the importance of examining ion and electron movements to assess overall battery performance.

All the stages in the electrochemical process (microscale, macroscale diffusion and intercalation) are numerically incorporated in Newman’s model. The governing equation derived from the 3D Newman model is central to this process, which uses a coupled thermal and electrochemical process to simulate battery behavior.

This model allows us to investigate the temperature distribution for different voltage and current profiles at different charging rates. Charging rates play a critical role in battery performance. The charging rate, defined as “C,” directly influences temperature generation and battery wear. For instance, a 1C charging rate means a battery fully charges in one hour, while a 2C rate halves the time. However, higher charging rates can lead to significant temperature generation, posing safety risks, whereas lower rates offer more uniform temperature profiles but require longer charging times. Thus, a trade-off between charging time and temperature generation rates is essential.

Additionally, changes in voltage characteristics can be investigated due to heat generation and charging rates. Based on the inputs, this analysis can select the most efficient cell type (cell, pouch, etc.) and the correct placement of tabs.

Advanced Newman’s model includes displacement effects called Coupled Temperature-Displacement Electrochemical analysis. This allows the examination of volumetric strains caused by temperature changes. This layered approach, based on the 3D Newman model, aids in optimizing battery charging strategies by providing insights into lithium-ion concentration, volumetric straining, temperature profiles, and potential variations across different battery types. Additionally, it can be used to analyze phenomena such as swelling-induced electrolyte flow, porosity evolution, stress induced by swelling, electrode architectures in 3D, etc.

A generalized workflow for electrochemical performance simplifies the analysis process, enabling efficient evaluation of cell behavior under varying conditions.

Generalized Workflow for Electrochemical Performance

Due to thin layers of cell components, it’s usually not feasible to perform the analysis directly in 3D with an exact representation of the cell. Usually, electrochemical performance analysis starts with a simple representation of cell components.

A P2D (Pseudo 2D) simulation for simplified cell component representation showcases the cell components in a planar representation. This process includes maintaining accurate volume fractions of anode, cathode, and separator in 3D. Once the P2D model setup is done, the material parameters are calibrated based on test data and Newman’s model to ensure a realistic electrochemical property simulation. The calibrated material model from the P2D simulation is then applied in detailed 3D Finite Element (FE) modeling, named P4D simulations, to evaluate desired outputs. This method streamlines the mimicking of real-world battery behavior through iterative material calibration and advanced simulations.

Beyond electrochemical properties, the mechanical performance of battery cells must be evaluated to ensure strength, stiffness, and durability under load conditions.

3. Strength, Stiffness, and Durability Analysis

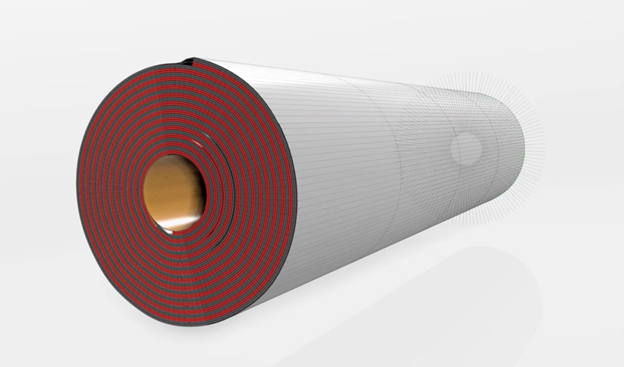

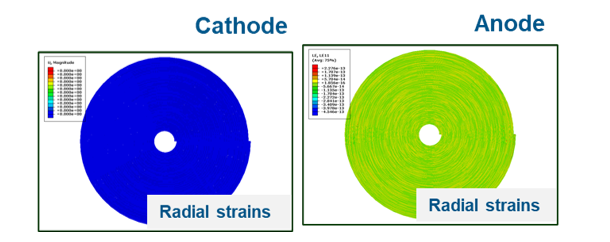

Evaluating cell design involves several steps, including examining electrochemical properties and assessing stiffness and strength. This evaluation uses a specially developed subroutine that addresses cell expansion or swelling due to changes in the State of Charge (SoC).

Different SoCs induce varying swelling behaviors in the battery. These behaviors are numerically modeled in a user subroutine for direct application. This approach explicitly targets cyclic swelling issues resulting from the ionic transfer.

Further analysis involves strength and stiffness, considering external loads such as axial compression, three-point bending, radial compression, and impact. The objective is to measure reaction forces generated under these load conditions to inform cell design decisions.

To address computational challenges, model order reduction techniques are applied, enabling efficient simulations while maintaining accuracy.

4. Model Order Reduction technique

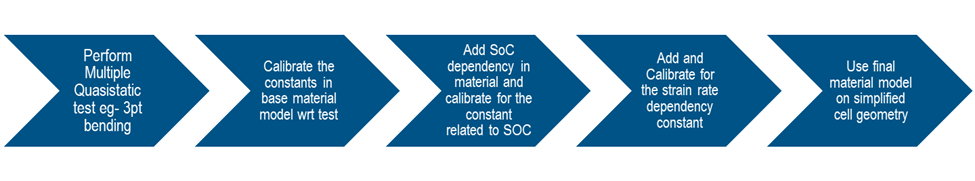

From a modeling perspective, a battery cell comprises multiple layers, including the anode, cathode, and separator. When modeling these components in either 2D or 3D, the resultant element count can become substantial, leading to increased computational time. This challenge is addressed by applying model order reduction techniques, which significantly reduce the model size. This reduction is achieved by calibrating the cell material’s properties using empirical test data, rather than relying on an exhaustive detailed modeling.

Advanced calibration techniques refine material models by aligning simulation parameters with empirical test data, ensuring accurate predictions across operating conditions.

5. Advanced Calibration Techniques for Cell Material Optimization

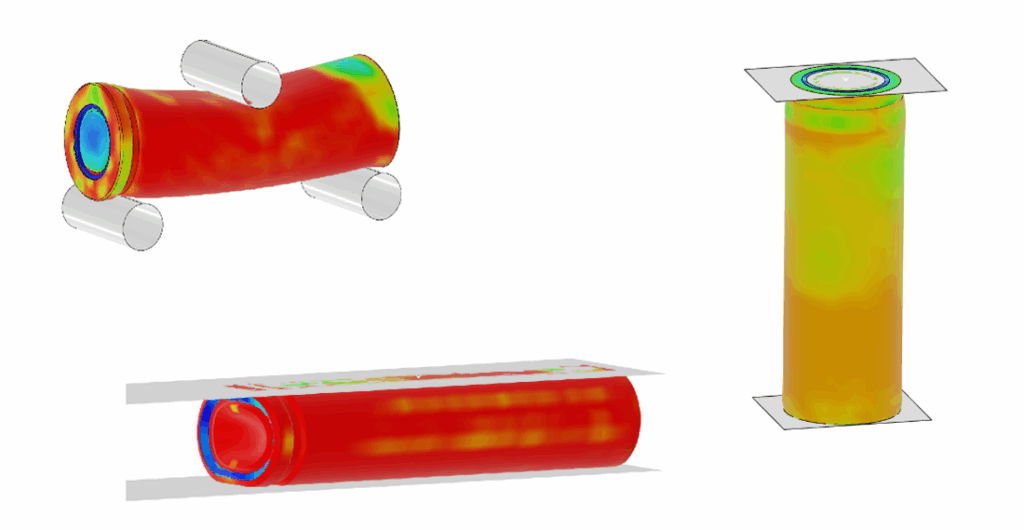

The material calibration uses optimization tools like Isight (or Process Composer App on 3DExperience Platform) to align the cell material’s behavior with empirical data. This involves adjusting parameters within selected plasticity models (for example, anisotropic or Hill’s plasticity) to match test outcomes. The calibration process entails performing standard tests (radial, three-point bending, indentation, and axial compression tests) and comparing the results with simulation outputs from tools like Abaqus. The simulation results are fine-tuned by varying constants until they align with the test data.

Subsequently, the material model incorporates State of charge (SoC) dependency by introducing a field variable, effectively modifying the material model to include an exponent (m) related to the SoC. This adjustment ensures that the simulation model accurately replicates test results across different SoCs. The material model is refined to account for strain rate dependency, aligning simulation outcomes with empirical data for specific strain rates.

This approach to cell design evaluation incorporates a thorough analysis of both electrochemical properties and structural integrity while using advanced modeling techniques to minimize computational demands. By meticulously calibrating material properties against empirical data and incorporating dependencies on SoC and strain rate, the methodology promises accurate and dependable predictions of cell performance. In this scenario, the single cylinder representation of the cell is sufficient (eliminates extensive preprocessing and reduces DoFs) since the material is calibrated with the exact material.

Understanding degradation mechanisms, including calendric and cyclic aging, is essential for predicting capacity fade and optimizing battery design for longevity.

6. Degradation: Calendric and Cyclic Mechanisms

Battery degradation stems from calendric aging, influenced by time and storage conditions, and cyclic aging, which accumulates during repeated charge-discharge cycles. These mechanisms contribute to capacity fade, internal resistance growth, and mechanical stress within the cell.

At the material level, one of the key degradation mechanisms is the formation and growth of the Solid Electrolyte Interphase (SEI). While the SEI is initially protective, it continues to evolve with cycling. Cracks on active particle surfaces expose fresh material, leading to SEI growth within surface fractures, which further consumes lithium inventory and contributes to capacity fade. Additionally, the accumulation of SEI reduces electrode porosity and active surface area, thereby impeding ion transport and slowing reaction kinetics.

SIMULIA’s simulation environment enables a coupled electrochemical–thermal–mechanical modeling approach, where degradation pathways such as SEI evolution, lithium plating, and stress-induced cracking can be integrated into the design process. By resolving these effects spatially within a cell, engineers can assess non-uniform aging behavior and identify local performance bottlenecks.

These insights feed directly into reliability-driven design decisions, such as optimization of thermal management, electrode architecture, and charge/discharge protocols. Given the computational expense of high-fidelity aging models, Model Order Reduction (MOR) techniques allow these detailed models to be simplified—retaining critical degradation behavior while enabling faster simulations at the system level, including BMS integration and control strategy development.

Thermal management strategies are critical to mitigating degradation effects and ensuring consistent performance across a range of operating temperatures.

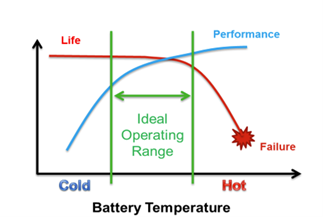

Thermal Management in Battery Cells

A cell’s thermal behavior significantly impacts its performance, with elevated temperatures leading to a marked decline in efficiency. Therefore, maintaining an optimal temperature range ensures the cell’s longevity and operational efficiency. In this context, CFD codes emerge as invaluable tools for the thermal design and management of cells. They provide essential insights and capabilities needed to optimize cell performance and durability, underpinning the importance of thermal management in battery technology.

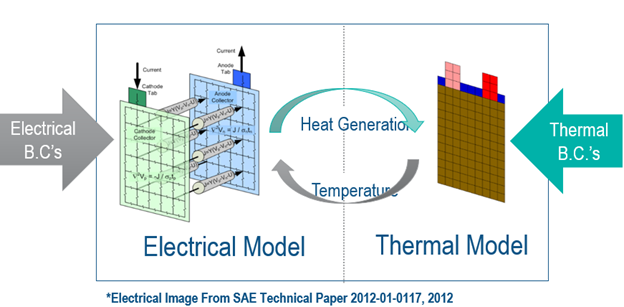

Integrating electrical and thermal modeling provides a comprehensive framework for optimizing cell design, accounting for interdependent thermal and electrical behaviors.

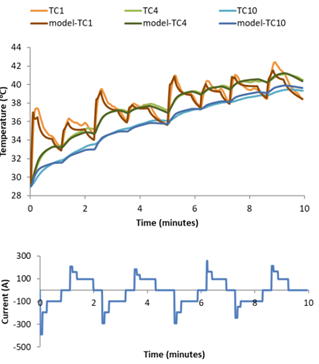

Integrated Electrical and Thermal Modeling for Enhanced Cell Design

In contemporary battery technology development, the interdependence of electrical and thermal phenomena is critical. Accurate modeling calls for integrating electrical and thermal models to avoid loss of precision. Computational Fluid Dynamics (CFD) tools like PowerFLOW enable simultaneous modeling, using voltage and current data to generate response surfaces for temperature, resistance, and State of Charge (SoC). This approach facilitates system-level updates, incorporating temperature effects through equivalent circuit models like the Newman, Tiedemann, and Gu (NTG) and the National Renewable Energy Laboratory (NREL). The methodology allows for precise temperature distribution calculations, essential for evaluating and optimizing cell design parameters such as tab size, location, cell area, and collector thickness. This integrated simulation approach is for designing electrochemical cells capable of withstanding various load conditions, ensuring their performance and safety in operational environments.

Conclusion

In this blog, we discussed key methodologies in battery cell engineering for electric vehicles, emphasizing a holistic simulation approach that integrates electrochemical, electrical, and thermal analyses. This ensures robust and reliable battery cells that meet diverse service conditions while prioritizing safety. We invite you to access our recorded session here for deeper insights into battery engineering. Additionally, you can check out our previously published blog on battery packs and modules here and battery cells here for more insights into the electric vehicle ecosystem.

Interested in the latest in simulation? Looking for advice and best practices? Want to discuss simulation with fellow users and Dassault Systèmes experts? The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.