The annual SIMULIA Regional User Meetings (RUMs) provide a forum for practicing engineers and researchers to exchange ideas and experiences in all aspects of simulation technology. At the 2025 SIMULIA America’s Users Conference (SAUC), Matthew Langford of Techsburg presented Advancing the Aerospace and Energy Industries with PowerFLOW. Read the full presentation in the SIMULIA Community, here.

Advancing the Aerospace and Energy Industries with PowerFLOW: Techsburg Customer Story

Challenge: Techsburg, an engineering services company with a focus on the aerospace and energy sectors, needed a solution that could tackle both aeroacoustic simulations for aircraft and unsteady fluid dynamics in gas turbines.

Solution: Techsburg used advanced simulation, specifically PowerFLOW, to accurately predict noise and fluid dynamics before physical testing. The lattice-Boltzmann method (LBM) solver used in SIMULIA PowerFLOW provided straightforward setup procedures and enabled rapid simulation turnaround time.

Benefit/Result: Techsburg saved time and resources by catching design flaws early, enhanced their competitive edge with high-fidelity analysis, and delivered precise, actionable insights to clients. Simulation paved the way for future advancements, including generating reliable training data that could potentially be used for AI-driven models to accelerate R&D cycles.

Introduction

Since its inception in 1998, Techsburg has focused on two of the most complex domains in engineering: aerospace and energy. Led by engineering expertise and a belief in practical, technical excellence, Techsburg defined itself by its relentless pursuit of answers. The company’s clients—from government agencies like NASA and military branches to aviation and gas turbine OEMs—bring impossible problems. Each project tests the limits of existing tools and traditional workflows.

Early on, the team supplemented wind tunnel and ground testing with traditional steady CFD tools, building a hybrid workflow that married physical and virtual experiments. But the real breakthrough came when Techsburg adopted PowerFLOW, an advanced Lattice Boltzmann method (LBM) solver recognized across the industry for its unmatched capabilities in unsteady fluid dynamics and computational aeroacoustics.

PowerFLOW enabled the team to dive deeper. Unlike standard Navier-Stokes solvers, this tool resolved turbulence and propagated acoustic waves with minimal numerical dispersion and dissipation. Results became more reliable, and simulations ran faster—a game-changer for Techsburg’s team.

“We’ve always wanted to give our customers the best answer possible — to answer questions about unsteady fluid flow and computational aeroacoustics. PowerFLOW is the best tool for the job. And we want to use the best tool.”

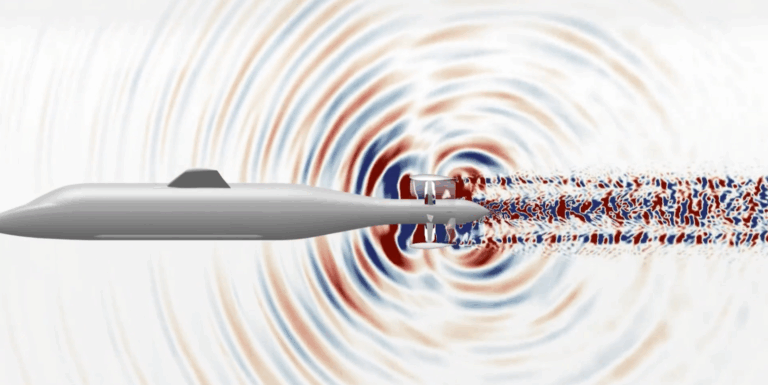

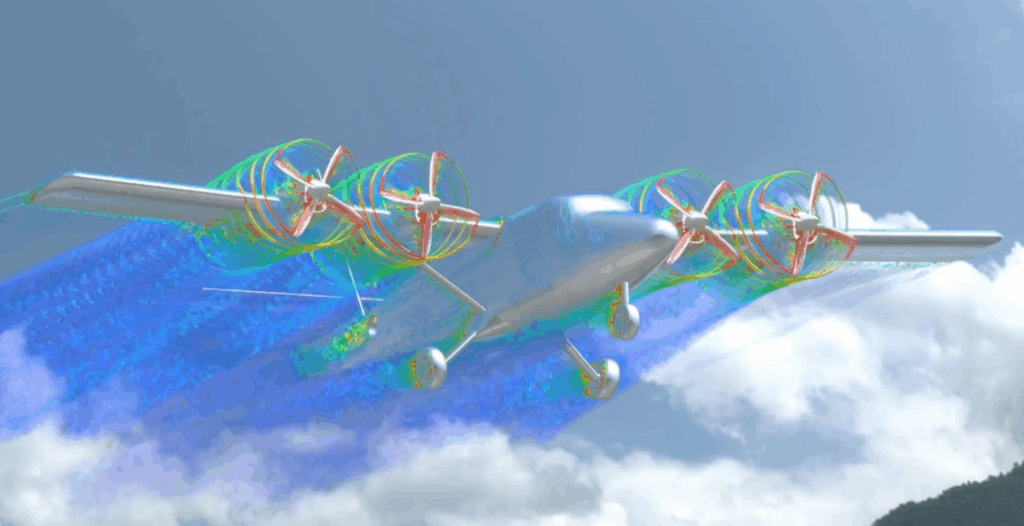

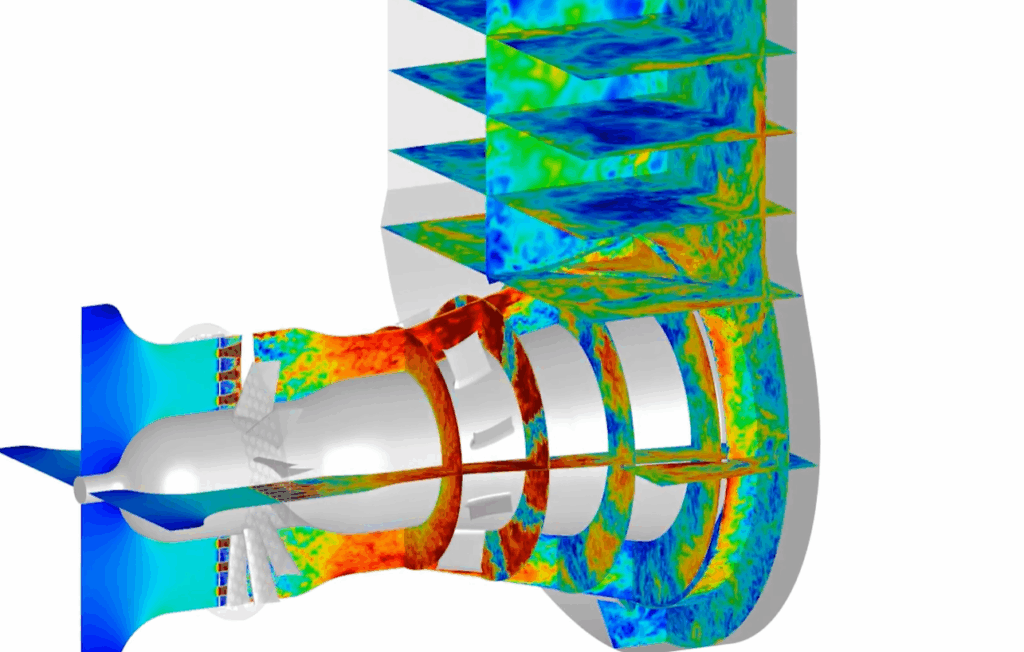

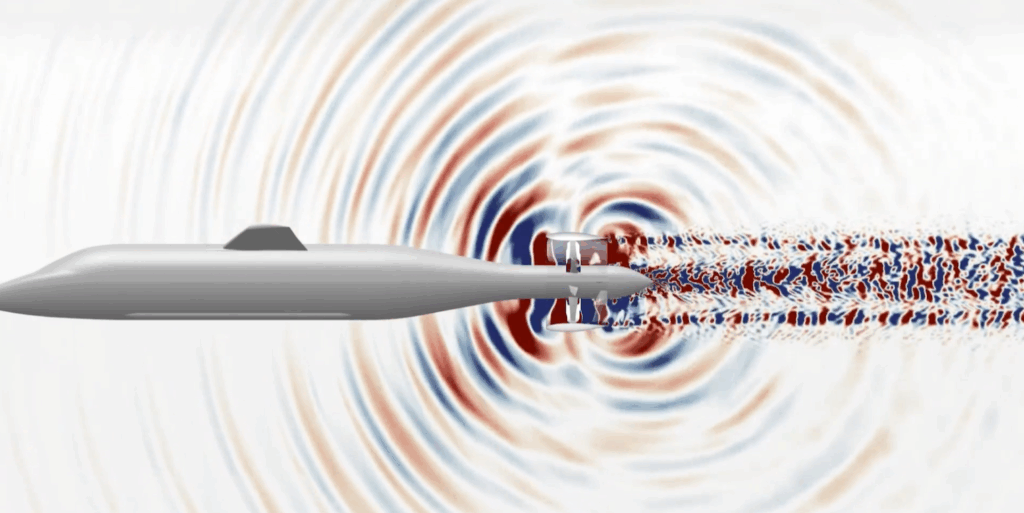

For the past five years, Techsburg has used PowerFLOW to tackle some of the most challenging problems in the aerospace and energy industries. From predicting the community noise of emerging aircraft concepts such as Advanced Air Mobility (AAM), electric ducted fans, and truss-braced wing airliners to optimizing the efficiency of the next generation of gas turbines for aircraft propulsion and power generation, they have used PowerFLOW as an efficient and robust tool for high-fidelity aerodynamic/aeroacoustic simulations.

PowerFLOW Performance: Scaled for Small Business

One of the most remarkable aspects of Techsburg’s journey is how they’ve harnessed advanced simulation technology typically associated with large organizations. While PowerFLOW is also deployed on massive compute clusters, Techsburg runs its high-fidelity simulations on just 256 CPU cores plus one GPU accelerator node, proving that world-class simulation doesn’t require supercomputer-level infrastructure.

This capability was highlighted in a paper co-authored with SIMULIA and presented at the 2025 Turbo Expo conference in Memphis, titled “Simulation Approach for High-Lift, High-Work Low Pressure Turbine Aerodynamics using the Lattice-Boltzmann Method.” In that work, Techsburg demonstrated: “Relative to Navier-Stokes DNS, the current LBM-LES approach resolved one order of magnitude smaller turbulence scales than the NS-DNS of Sandberg et al., at two orders of magnitude lower computational cost per throughflow: 250 vs. 38,800 core hours per throughflow for a similar 2.5D LPT airfoil computational domain.”

This benchmark underscores a key differentiator of PowerFLOW: it enables smaller organizations to perform simulations of extraordinary fidelity and efficiency without the need for vast compute resources.

As Matthew Langford put it during his interview at the SAUC:

“It’s definitely a more commonly used tool in enterprise environments. But we’ve leveraged it as a small business to provide something that our fellow small-business competitors typically don’t. So it gives us a competitive advantage, a leg up, some uniqueness in the market.”

The Noise Problem: More Than an Annoyance

For civil aviation clients, a noisy aircraft can mean reduced sales and/or failed certifications. For defense projects, the stakes escalate—noise means detectability, which can compromise missions. Military aircraft must operate quietly to avoid being heard or detected by observers, making it crucial for engineers to address one of the most elusive problems in aerodynamics: predicting the noise generated by an aircraft before it has even been constructed. This is no small feat, as aeroacoustics can be highly unpredictable and vary significantly based on design configurations.

With increasing threats worldwide, the need for aircraft with low observability has never been more pressing. Yet, the conventional approach to aircraft design isolates airframe and propulsion engineers. They often merge their systems late in the design process, with little regard for the acoustic consequences.

Techsburg focused on solutions powered by advanced simulation tools to address this challenge. Their use of PowerFLOW remarkably enhanced their simulation capabilities, allowing them to accurately predict the noise characteristics of various aircraft configurations. This simulation-driven approach allowed engineers to simulate a broad spectrum of propulsion systems—propeller, ducted fan, or rotor—integrated into aircraft designs. Before physical testing begins, they can generate data that indicate how these components will operate in real-world conditions, significantly reducing uncertainty.

Energy Sector: The Battle with Unsteady Flows

Meanwhile, gas turbine manufacturers in the energy sector wrestle with another formidable opponent—unsteady flow dynamics. With performance and reliability on the line, legacy simulation and test tools often fail to capture the turbulent complexities inside turbine stages and exhausts—the consequences: system inefficiency, unreliable results, and costly testing.

“PowerFLOW has been transformative. It’s like getting this shiny new toy. And I just want to show it off to all my friends. The capabilities are amazing and the results are trustworthy, allowing us to solve problems that would otherwise not be solvable or at least not solvable without immense effort.”

For Techsburg, the integration of PowerFLOW enables them to tackle these unpredictable behaviors in turbine stages and exhaust systems effectively. By implementing advanced simulations, they can predict performance and gauge the efficiencies of their designs ahead of time. PowerFLOW allowed Techsburg to model unsteady flow in turbines with accuracy that outpaced conventional approaches.

Wind Tunnel Testing: Simulation Saves the Day

One project that brings these advances into sharp focus is a contract that involved a wind tunnel test of a strut-braced wing with a deployed flap, conducted by Techsburg in conjunction with partner company AVEC. Since this wind tunnel test was focused on measuring a particular airframe noise source (the wing/strut junction), any extraneous acoustic sources could have sabotaged the test objectives. As a risk mitigation measure, they decided to run aeroacoustic simulations of the test model in PowerFLOW. The simulation results clearly showed that seemingly benign mechanical supports in the model were nearly as loud as the junction source they intended to measure. By virtually identifying this easily-overlooked detail, the team prevented a costly failure. They redesigned the model supports in tandem with further PowerFLOW aeroacoustic simulations, met all of the test objectives on the first attempt, and protected tens of thousands of dollars in test resources.

The narrative was the same for each project: simulation wasn’t just a tool but insurance. It meant catching errors before they multiplied through the design process and into production, ensuring that there were no surprises once the deliverables were put to the test.

Conclusion

Where most advanced simulation tools are reserved for enterprise teams, Techsburg carved its advantage as a small business. PowerFLOW provided answers competitors couldn’t match. The team’s specialized expertise, amplified by this technology, helped them leap ahead—offering clients technically sound and unique solutions in the marketplace.

Today, the pace of Techsburg’s journey only accelerates. The team isn’t content with resting on current workflows. Instead, they’re already using simulation data to train AI-based models. The vision is clear: machine learning-trained surrogate models, running on the backbone of robust simulation data, will allow engineers to get precise answers in seconds, not hours or days. This will redefine speed and accuracy across both the aerospace and energy sectors.

Techsburg’s story shows what happens when a company refuses to work within the limitations of traditional tools. By adopting advanced simulation—first to complement and then to redefine their processes—they elevated their work from routine engineering to industry-defining innovation. Techsburg’s PowerFLOW story stands as proof: the right tools and the right minds can solve the unsolvable.

Interested in the latest in simulation? Looking for advice and best practices? Want to discuss simulation with fellow users and Dassault Systèmes experts? The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.