_________________________

Please introduce yourself.

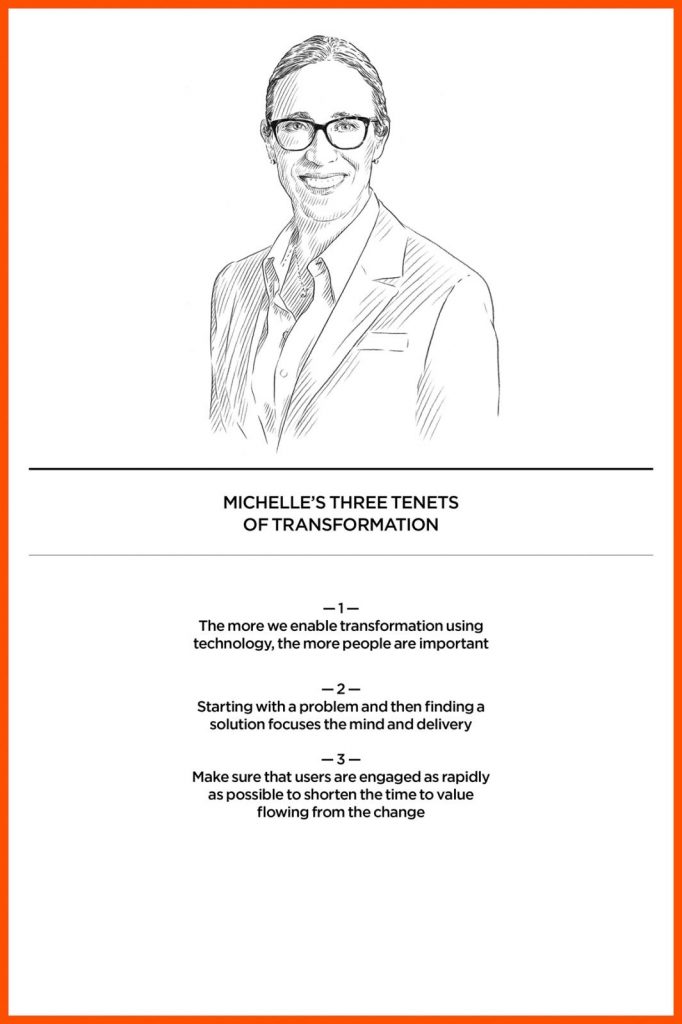

My name is Michelle Ash, I’m currently the CEO of GEOVIA. I’ve been in mining now for about 30 years, and over that period, I’ve been in both operating roles – running mine sites, general manager of mine sites, chief operating officer for Acacia – and I’ve also been in many strategic roles; I’ve lived in Africa, Australia, South-East Asia and most recently in Canada. And now, I’ve made the move to be part of a technology business, because what I’m passionate about is helping transform the mining industry.

One of the ways I believe I can be most helpful is on the technology side – looking at mining and infrastructure and bringing some of the capabilities from other industries, which will supercharge the transformation process of our industry.

So, what would your job title be?

The easiest way to describe myself is as a ‘transformation specialist’. In the last 15 years, most of my roles have required significant transformation – improvement of safety and turnaround of production. For instance, when I was in one of my roles in iron ore it was because we had had a few fatalities. They needed the safety performance radically transformed and changed. In some of my recent roles, they needed the relationship between the government, the community and the mines to be radically transformed. And now, using software or technology.

I’m also on civil boards of startups, as well as the chair for GMG, which is an industry association also looking at transformation. But my technical background is as a civil engineer; I moved into mining basically straight away. Later on, I did an economics degree and a psychology degree, and then an MBA. And what I find most interesting is how we can buy technology, people and business models to create new ways of working.

I became a mining engineer to start with and then I slowly got more interested in how to drive performance; how do you encourage people to do things differently? So that’s why I got involved in psychology, to try to understand how to motivate people to change, and to make changes. That led me into leader-led transformation. And more recently with Barrick Gold, we set up a continuous improvement process. I headed up business improvement. We then started looking at digital transformation, and how you can use digital technologies, as well as leader-led transformation.

That led into me getting more interested in technology – everything from blockchain, to the use of robotics and automation through to AI and digital technology.

From your point of view, what are the biggest challenges to the mining industry in the future?

I think absolutely the biggest one is changing opinions, changing expectations of society, of people, of citizens. And how that then affects communities and governments, and how they interact with mining companies. And you know, that’s everything from investors. And we’ve seen the rise of ECG invest interest. We used to call them sort of fringe or sustainability investors. And they used to be this very small group. Now, they are part of the mainstream. Whether that is governments changing legislation, or insisting on different standards; ever-increasing standards, which I think is a positive thing; or if it’s communities expecting different jobs, or different ways of creating wealth from mining companies.

You know, they don’t want to just do light jobs within the mining industry – truck drivers and those sorts of roles. They want more sophisticated roles. Automation engineers or robotics engineers, etc. And the changing attitudes and changing thoughts of young people, and whether they want to join the mining industry, and why they would join the mining industry, and what they would seek to achieve and get out of that.

So, I think these changing expectations are certainly the biggest challenges. Because they impact everything else. For instance, commodity prizes, Covid and pandemics, and things like that, causing a change in the way we work. All of those are sort of summed up in these changing expectations. And what then changes within us – mining companies having to drive towards carbon neutrality, or needing to automate; or mining companies needing to rethink how do they distribute wealth.

We need to work with governments and communities on all these issues, because it used to just be about royalties and taxation and jobs. Now, it’s much more. So, I think there’s all these different resulting pressures from changing expectations. And certainly, over the 30 years that I’ve worked in mining, I think there is a lot we can be proud of in terms of our radically changing our safety performance and our environmental performance. Significant changes in the way we go about doing our business, and the productivities we can achieve.

I think the ways in which we are changing and the rate at which societal expectation is changing, we are actually getting a widening gap between our performance and that of society. Not because we’re not changing and doing things differently, but just that the rate of change, of expectation, is so much higher now. So, we have to increase our rate of transformation, and rethink fundamentally some of that process.

“One of the keys to this transformation that I’m

talking about is the better use of data.”

How do we improve system integration and applications along the mining value chain?

I’ve painted a very macro challenge to the mining industry. But one of the keys to this transformation that I’m talking about is the better use of data. Mining companies, typically, produce an enormous amount of data on a daily basis.

We produce expiration data about geology and coal, we’ll produce mining data about trucks and processing plants and blasts, and environmental things. There’s all this data that we’re producing. Yet, one of the barriers to us transforming, and really being able to make the best decisions we can as fast as possible, is the fact that our data is still very compartmentalized, or ‘siloed’. The heritage data, and all the community data, is kept separate. The mining data is kept separate, etc.

We see tragic consequences of this. Most recently in Rio Tinto, for example, they had a blast that destroyed a 46,000-yr-old cave in a sacred site of the indigenous people in western Australia. And it wasn’t that they did that deliberately. I’m absolutely certain what happened in that situation is that the operational data, the mining data, was in a very separate place to the heritage overlay data; to the community data and information. And the two just didn’t come into one place. In that case, a very sub-optimal and tragic decision was made.

If we can integrate that data, then we can start rethinking some of our systems, and improving them.

“One of the keys to system integration is first to have a

single software platform that allows you to integrate all of that data.”

One of the keys to system integration is first to have a single software platform that allows you to integrate all of that data. And again, we see many solutions at the moment that either work on economic data, or they work on three-dimensional mining, design data. Or they work on chemical data. Very few that actually bring all of those together and allow you to see simultaneously economic data overlaid over three-dimensional information; overlaid over chemical information, for example.

So, I think the key to integrating these systems is to have a cohesive data model, to have a single source of truth and a platform that allows you to visualize and to see and understand all of that data. I think part of that is this concept of interoperability – this ability to be interoperable, to connect and to interconnect both data and information from different sources.

“And I think part of this is mining companies’

real competitive advantage is the speed

at which they can adopt technology into

their business that solves a business problem.”

How can the process of adaptation of these innovations be catalyzed?

I think part of the answer is looking at solutions that are already available in other industries. So, if the mining industry doesn’t have that sort of a platform, the aerospace industry certainly does. And car manufacturing; all the transport or mobility industry certainly does. So, I think there are good examples to have a look in other industries.

I think there’s also good examples of how other industries have worked collaboratively to create some of these systems. Now, when I say work collaboratively, work collaboratively with the mining companies themselves in this case. The suppliers, the academics, the governments, the whole ecosystem, the startups etc. And you know, a good example of that is the car industry. They really have worked very hard to catalyze innovation and change by being very clear on the small details – the few things that they should compete on, and the many things that they should work collaboratively on. In fact, to create competition. And you know, it’s not as if the car industry is any less competitive as an industry.

So, I think some of that is thinking through, “how do we compete and how do we collaborate? What is our competitor advantage in the industry?” Especially as mining companies. You look at a lot of mining companies who want to clamp down on IP. But, I’ve been in this situation where I’ve been arguing with a mining company inside a mining company. You know, what are we doing with this IP that we use? How are we using it to our advantage?

So, what I see is a lot of mining companies locking IP up, but they’re not necessarily making the most of it themselves. And then, certainly, retarding the rate of change in the industry, because that IP now is not available to others to build. And I think part of this is mining companies’ real competitor advantage is the speed at which they can adopt technology into their business that solves a business problem. And then not just solve that problem once, but replicate it or scale it across the multiple mine sites.

What I see too often in mining companies is that we’ll do all these little experiments, basically; we might implement a technology at one of our sites, but then that’s where it stops. We don’t then go, “okay, their technology is an advantage and solves that problem”, for that site. And of course, this site and this site would also have that same problem, so let’s replicate it.

Now, for me, the mining companies, I can identify the problems that need to be solved, identify the technologies that are at least suitable. Maybe not even the best, but suitable at solving their problem. Working collaboratively with the rest of the industry to strengthen those solutions. And then to rapidly implement those solutions across multiple sites.

They will be the companies that will win and be the most successful in my view, moving forward. Because they will be considered to be solving problems, they will be increasing their profits. They’ll be attracting the younger workforce, the workforce of the future. They’ll be catalysing change even within their existing workforce. They will be improving safety, which of course increases morale, drives productivity, drives profitability. There are so many advantages to that being the focus for mining companies.

“If you really want the transformation

you have to then have integrated solutions.”

So, what is the maturity level of digital systems or industry 4.0 practices in the mining industry today?

Well, it’s better than it was four years ago. I could have named on one hand the mining companies we could go to, to talk to about how they are transforming digitally; how they are dealing with the industry 4.0. Do they have sensor technology out there in the field? How are they integrating that, how are they using the data, for instance? All of those questions were completely foreign. In fact, even understanding cloud technology was completely foreign. I think now we’re starting to get a greater tipping point towards mining companies engaging in these sorts of technologies.

As I said, I think it’s still two-point solutions and not integrated enough, but at least point solutions are a good start. But if you really want the transformation you have to then have integrated solutions. I think though as a whole, there are still too many mining companies using Excel spreadsheets, using archaic filing systems to share data or to save data, and therefore not really sharing data. And there are quite sophisticated platforms out there. And they could leap ahead, because as I said, there are other industries that have gone ahead. And I think also the willingness of mining companies to work with suppliers.

So, improve and adopt and adapt! It’s getting better, but we need to be thinking that this has to happen quickly and work faster.

Tell us about the workforce transition that is happening across mining.

Again, it’s a tale of two cities, as such. And most of the mining industry, in most of the developed mining countries – everywhere from Chile to Russia, Australia, Canada, North America – have quite mature and ageing workforces. So, I think the last statistic I heard in Russia is something like three quarters of the industry will be retiring in the next 15 years. Australia isn’t far off that. At least it will be a good half, if not more, of the industry will be retiring in the next decade.

So, we’ve got a great, mature, very experienced, very knowledgeable workforce. And then we’re starting to have to bring in this younger generation. And I think being attractive to the younger generation is somewhat challenging at the moment, because young people think that mining is archaic, it’s dirty, it destroys the earth rather than adds value.

Now, in part that’s because we are somewhat distant from where our vitamins come from, where our food comes from, where our pots and pans come from, where our mobile phones come from. But some of that is also because of some of the disasters that we’ve had in the industry. And frankly, the limited technology evolution that we’ve had over the last 20 years.

So, I think for that workforce, we need to work out how we become more attractive. How do we attract younger people into the industry? Because we need them desperately. They are more interested in automation jobs, the robotics jobs, the remote operating center jobs; working with drones and working with some of this great equipment to solve problems and work in fundamentally different ways. Far more collaborative, much more eager to talk out and talk about issues that they see and solutions. And we’ve got the aging workforce that have great knowledge, great experience.

When I was working with Barrick Gold, we introduced technology into that workforce. Since we worked with them to introduce that technology, they were actually very receptive. Because they wanted to do things differently. One of the most surprising things that we did was introduce automated drills, and we got the drillers to work with us to bring in these automated drills. So, they were the ones that were actually driving a lot of the change.

The workforce is changing, even in developing countries where you might have a younger, on average, workforce. My experience in different African countries is the thirst for knowledge, the thirst to improve, the thirst to be able to adopt and adapt new technologies. So, I think there is a transition happening in the workforce, especially in the developed countries, and in some of the countries that have less developed mining industries. I think there’s a great opportunity to further develop a very different workforce.

If we automated the data integration, from these 3D big data technologies, what opportunities would be unlocked for mining companies?

For me there are four major problems we need to solve in the mining industry. The first is global ore body intelligence. We need to be able to find ore bodies faster, cheaper and more completely. I think in that huge opportunities exist for satellite imaging to detect and use physical geo-spatial and hyper-spectral technologies in order to overlay and add additional data to a geologist’s capabilities. In order to augment the decisions that geologists make, either to continue with the drill program or to start a drill program. I think there’s a lot in terms of core logging that can be done, where you can sort of instantaneously, not only log core, you could even get in the field chemistry. And get far more real-time data of exactly what is happening in the expiration hall itself. You know, start a lot faster, thinking about a building.

A second broad problem that we’ve got to solve is around automation and electrification – understanding performance, optimizing performance in real time, and optimizing planning in real time.

The third big problem is really around precision extraction – how do we just take the metal ideally that we’re interested in and leave the rest of the waste behind? And then, how do we process that? I think all of that process is around smart design – using digital twins to create simulations before having to build in real life with sensors. Making predictions, from those sensors, how to apply this.

Then, the final problem is really the one around creation of social value. So how do we create and distribute value to our communities? I think there’s an opportunity using technologies in that space. For example, a lot of our communities are rural, agricultural communities. And we bring sensors into those communities to monitor our environmental performance. Those same technologies could be focused on agricultural performance, to help better crop development. Similarly, we bring in automated equipment. Could we also automate equipment for our local community, so that the agricultural production can be more efficient and effective.

I think there are still plenty of opportunities for some of these technologies to help transform the way we think about our collective environments.

“X-ray machine and software technology establishes

a new standard in mineral extraction and core analysis.”

What applications do you see for the Orexplore suite of products?

X-ray machine and software technology establishes a new standard in mineral extraction and core analysis. Interestingly enough, when I was with Barrick, we looked at these sorts of processes to try to distinguish between ore and waste.

Again, it’s this issue about precision extraction that we spoke about, or the problem around “how do you more precisely extract?” If you can more clearly identify, “oh, this is waste”, then it’s a huge advantage. You can’t express or obviously distinguish between ore and waste, because ore and waste is an economic term. But you can distinguish between the mineral that you’re interested in, possibly, and the mineral that you’re not. And so, it gives you another image that you can use along with other core data.

Certainly, once you get into operation, the ability to distinguish in between ore and waste is a huge advantage in terms of improving your mine planning. It’s a great input into your mine planning process. And then obviously, once you get into the operation component, as you actually start extracting, being able to use these sorts of technologies and software, finding your process implant. I think these sorts of products are actually very, very useful as another way of getting data through the whole process.

What role do you see for automation of workflows, as well as, machine learning and AI approaches?

There’s a huge opportunity to automate different parts of the workflows, or entire workflows; where you can augment what people do by taking away a lot of that replication process.

When I think in terms of machine learning and AI, I think of using those tools to augment human decision making. Because often in mining, we have much more work than we can get around to doing, and because of that we don’t necessarily run lots of optionality into our decision making. We sort of make the best quick decision that we can, and normally based on good experience, etc. But you know, is it the optimal decision? So, if you’ve got data that can be analysed, and then information that is provided in a timely manner to a person in the process, they can then use that information to make good choices.

I think the same with machine learning. You have to be very careful about your use cases, and then you need to be very sure about whether you’re supervised, unsupervised. How you create the learning capability of the machine, what its algorithm is, what its biases are, etc. So, you know, there’s a whole raft of things to think through.

For me, where AI and machine learning is really helpful, is if you want to move people to more sophisticated decision making and more sophisticated work. You can use the computer to take away a lot of the replication. Where you can help augment the decision making of people to give them the ability to make better decisions, faster. Or where it’s difficult and we can’t get the data fast enough, or we can’t understand the data fast enough. Therefore, we can speed up the process by using computers to find that data, take that data and create better decisions, augmented decisions for the people in that process.

“Every time we move a ton of waste, there’s a pesky law of physics

that says, to move a ton of any material a certain distance,

you’ve got a minimum amount of energy that you use,

no matter what that energy is.”

What trends and initiatives do you see in the industry from a sustainability perspective?

For me, the most profound initiative in the mining industry for sustainability is reducing the amount of waste movement. We are mining very low amounts of the commodity for every ton of waste that we move. So, gold mining, for example, we’re moving on average about ten tons of waste for every five grams of gold. In copper, it’s closer to about 80-90 kilos for every 8 or 9 tons of copper waste. Even in iron ore, we would move on average about a ton of waste for every ton of iron ore, which is at around 65%.

Every time we move a ton of waste, there’s a pesky law of physics that says, to move a ton of any material a certain distance, you’ve got a minimum amount of energy that you use, no matter what that energy is. And it causes all the other things to go into moving that material. So, the more we focus on moving less waste, the more we will fundamentally change our industry and drive its sustainability.

Do you see this happening right now?

There are a number of initiatives trying to drive waste down. Everything from sorting through to using the technology we were just speaking about, at Orexplore, to try to define waste and ore better. Which would be not only in exploration. Could you use Orexplore in terms of finding ore bodies faster with less effort, therefore less steel and diesel, etc.? But also, trying to move less waste.

I see more and more mining companies putting in solar fields and solar energy. So again, we’re starting to see more and more of this. I think there are definitely steps being taken. There is one in Canada that is owned by Newmont, for instance. It’s an electric mine, so everything underground is electric. So, the trucks, the drills, even some of their other equipment – all electric. I think there are definitely steps being taken to achieve zero carbon.

You were on the list of 100 global inspirational women in mining. What does that mean to you?

It was a little embarrassing actually, because I wasn’t entirely sure that I was worthy of such a thing. Because there’s a lot of fantastic women worldwide. But I was very honoured that people would think enough of some of the work that I’ve done; some of the work that I’ve done in different teams, with different people. And help catalyse, I guess, some change. Ultimately, I think it means we are getting more fantastic women in the industry, that are making a difference.

I think it’s important because one of the things that drives transformation in an industry, one of the things that drives innovation, is to have diversity. And whilst diversity doesn’t stop with women, and definitely shouldn’t and doesn’t, it is at least one of the ways you can spearhead diversity, by at least getting a better gender balance.

And more and more, we’re also getting indigenous groups, or cross-gender groups, or other groups into our industry. Because we’re creating this better understanding of how to work with different cultures, work with people that don’t think the same way as I might think as a leader. And how do you utilize those skills and talents?

Who do you think we should interview next, and why?

That is a really good question! Andrew Renolds. He is working in the field of innovations, and used to work for the Canadian government. He is now working in a startup where they really try to rethink the mining business model. Because, and I agree with him, I think part of the transformation in mining is to also fundamentally rethink the mining business model, to drive more value for all of the stakeholders within the mining industry. So yeah, Andy Renolds would be a good person.

And what would you like to ask him?

What would it take to fundamentally change or fundamentally drive the greater creation of social value through mining?

How do we integrate new technology? How is that done?

I find this challenge with all of the startups that I work with, and you know, as I said I work with seven at the moment, there are three parts to a compelling product.

One is that it technically works, and it’s got some technical advantage. The second component is that it needs to have a compelling business case. There is an emotional, as well as a practical, change to processes. And so, it has to be worth it financially. If it’s going to make a significant business case, it has to be a viable alternative, something that really changes the paradigm. And then the other one that we often forget about is it has to be desirable. It has to be a product, put in a way, that the end user loves using it. It solves problems or pain points that they’ve got; it makes their work easier and is ‘human’ while doing it. But it’s tough. You have to have those three compelling parts to the proposition that you’re offering.

___________________________________

Name: Michelle Ash

Age: 47

Lives: Melbourne, Australia

Title: CEO GEOVIA, Dassault Systèmes

Career in summary: Approximately 30 years’ experience in the mining industry in both operational and strategic roles, across commodities and operational types. More recently CIO for Barrick Gold, and now CEO Dassault Systèmes focused on technology enabled transformation. Current Chair of GMG and industry association focused on collaboration to drive innovation in mining; other mining innovation boards such as Mirarco and CMIC; also part of several start-up boards including Railyveyor, Behault, MineSpider, Indimin, StratumAI and OffWorld.

______________________________________