Discover in this “Sustainable transformation” series, how a coal mining operation successfully transforms into a sustainable lithium producer leveraging virtual twin technology. In this post, we examine how Mina Vieja and its general manager, Claude Gonzalez, begin to identify and work towards a new future as LithaNova.

Seize the Opportunity

After much discussion, the senior management of Mina Vieja, a long-established coal mining owner/operator, concluded that it’s time to transition out of coal and into a renewable and sustainable product. General manager Claude Gonzalez was given the task of identifying possible options for a new product, and determining how Mina Vieja would make the transition out of coal mining and into that product over time.

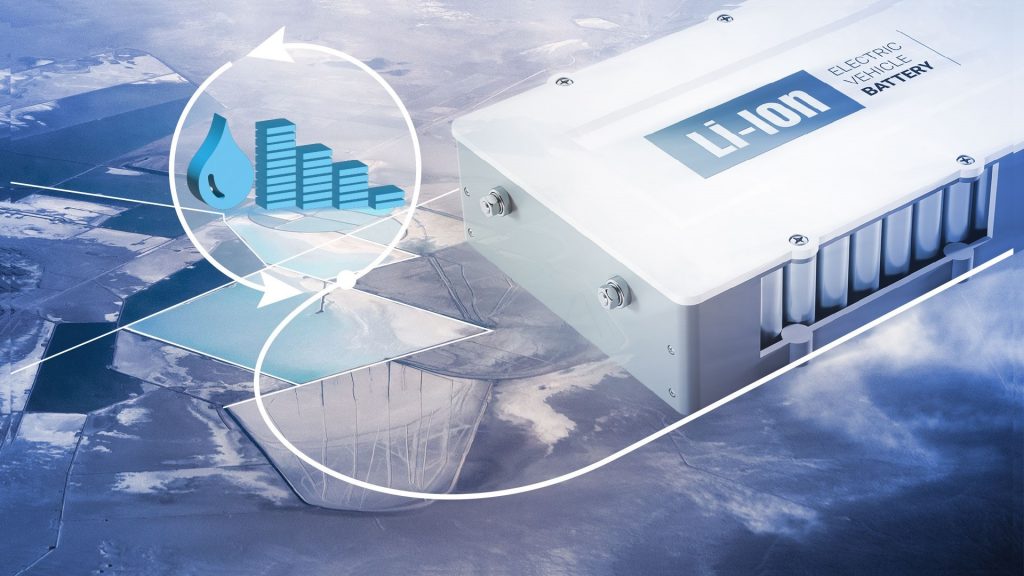

Claude began by assembling a small team of experts from across the company. Together they identified that lithium –– essential for building the batteries required for electric vehicles as well as mobile phones and a myriad of other cordless devices –– might be the product they were looking for. However, while the team recognized that there is significant economic opportunity in lithium, there are two major issues they would need to address before they can take the next step.

Issue 1: Current practice

Large quantities of lithium can be found in natural, flat expanses of ground covered with salt, called salars, located in the deserts of South America. Some of these salar fields host large volumes of water with a high concentration of lithium salt, known as brine.

“Currently, the method to produce lithium from the brine is to pump water from beneath the surface and let it evaporate over a period of 12 to 18 months in massive fields,” said Claude. “The problem is, while it’s cheap to produce lithium this way, it’s also very slow, and it’s affecting another resource –– water –– that the world cannot afford to waste. With climate change, water is becoming scarcer in many places, including South America, and we simply cannot continue to remove it, especially from sensitive environments.”

Claude and his team decided that they could only move into lithium production if they could identify a new, faster method for mining it that would also retain water in the environment rather than letting it evaporate.

Issue 2: Changing market

The lithium market is currently in a state of transition. Global demand for lithium-ion batteries is increasing quickly, but the performance of these batteries is not yet as high as it could be. Manufacturers and consumers alike want batteries that are denser, store far more power, and last longer. “To build batteries that can meet those requirements,” said Claude, “battery manufacturers and electric vehicle makers need high-performance electrolytes made of high-purity lithium. On top of that, they also need those electrolytes to be compatible with the latest developments in electrode materials.”

Claude and his team determined that, in addition to developing a new, sustainable process for mining lithium, Mina Vieja would also need to identify a method to turn the lithium they produce into high-performance electrolytes that can then be tailored to meet the specific needs of individual manufacturers and their chosen electrodes.

Continue reading on The Sustainable Mining Network community.