In Part 1, we explored mining in 2050 and what that would look like in the future, from robotics and the billions of IoT devices that would exist by then, to the impact on natural resources and even extraterrestrial mining.

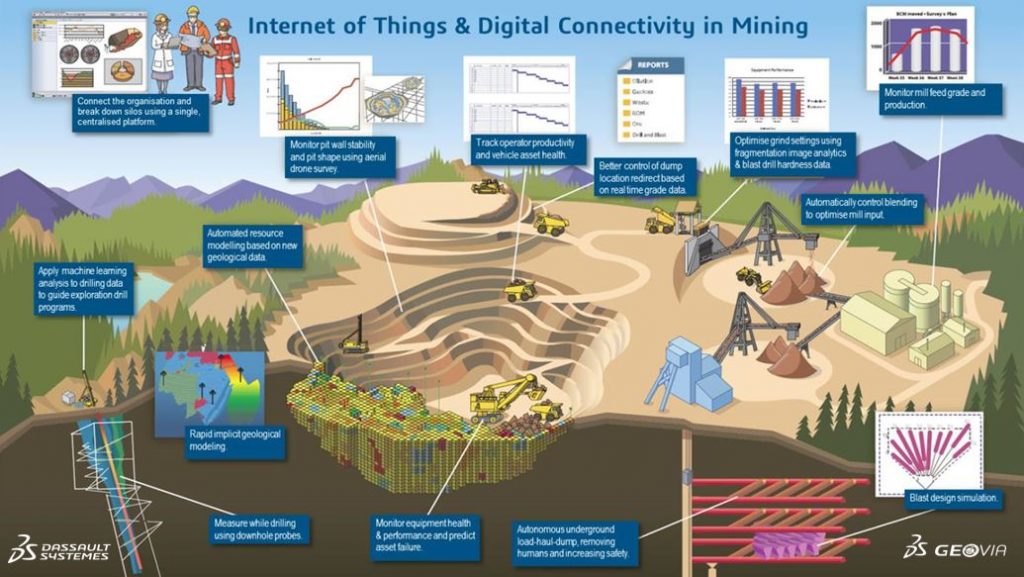

Jeff Hamilton, Director of Strategy & Alliance, GEOVIA, at Dassault Systèmes, continues with this theme by talking about the Internet of Things, where it’s used in mining, challenges that must be overcome and the opportunities to disrupt the status quo with IoT.

What is IoT?

IoT is a network of cyber-physical devices comprising embedded electronics, sensors/actuators, software and network connectivity. It supports other technology such as big data, analytics and machine learning. Today, many people think of common household items such as smart homes, switching on your lights when you come home, connected toasters and self-aware coffee machines when we talk about the Internet of Things.

This post will, however, focus on the industrial applications of IoT, commonly called the Industrial Internet of Things or IIoT.

The promise of IIoT is to unlock these silos of information that are usually held up in proprietary systems and connect sensors directly so data can be collected from across the operation and made available for decision makers.

So what has IoT got to do with the 4th Industrial Revolution? In simplest terms, the fourth industrial revolution or Manufacturing 4.0, as it is being called, refers to the digitalization of virtually everything related to product design, engineering, production and support – and IIoT is at the center of this. In this 4th industrial revolution, machines are not just automated, but they are ubiquitously connected to cyber systems that monitor, learn and respond to changes in operating conditions. The Internet of Things has a central role to play here.

Arguably, these changes can be considered more evolutionary than revolutionary right now, but the impact of the digitizing of everything will soon be more obvious in everyday life. With fewer people involved in actual manufacturing and computers taking over a growing number of other occupations, society will refocus on other human needs. More people and intellectual energy will be focused on the arts and entertainment, interest in “making things” will shift from physical things to digital things. Tomorrow’s “manufacturing” job is more likely to be writing computer code than bolting parts together. Various government and social organizations are even contemplating such radical changes as a universal income (everyone gets paid, work is optional).

The Mining Internet of Things

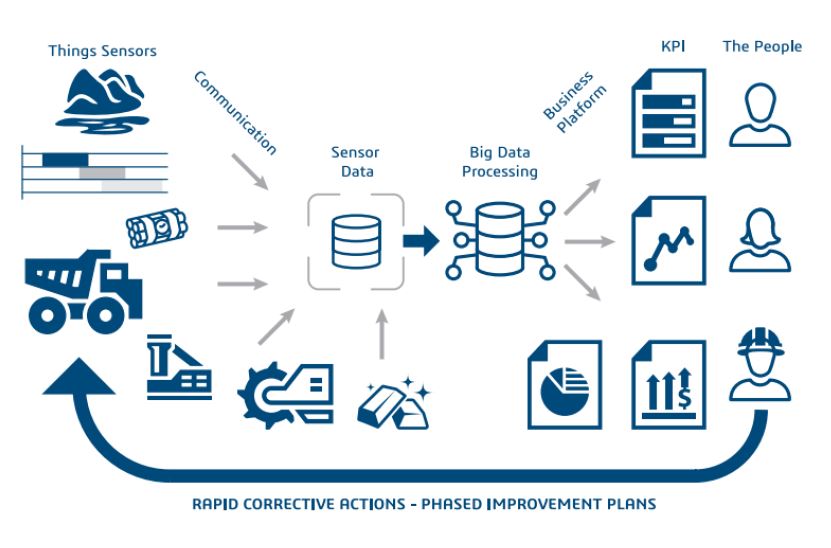

At Dassault Systèmes, we see a future where the things are connected to a central big data processing store where we can apply machine learning and autonomous systems to be more agile and react to changing conditions in the mine. The mining IoT will be:

- Digitally connected – all systems connected and monitored centrally

- Data driven – meaning new data available (such as new drill hole information) will drive real time decisions and redirect the mine plan

- Model based – allowing geological data (for example) to automatically influence and affect the current mining schedule, as they are inherently linked through a common data model

- Virtual + Reality – being able to simulate and play forward scenarios to select the one that is ultimately replicated in the real world

Read an in-depth analysis of Mining IoT here

Listen to Jeff explain IoT and the 4th industrial revolution in the below webinar, originally presented at Mining Indaba in South Africa.