By @Chawki JREIGE, GEOVIA Senior Industry Process Specialist for AusIMM Bulletin.

A unified design environment greases the gears and removes the friction between individual components of the mine design process, allowing for rapid updates across upstream and downstream workflows and easy team collaboration. Plus you can run all the ‘what if’ scenarios you want.

Strategic mine planning and pit design sit downstream of a host of other necessary tasks, such as resource modelling and geostatistical analysis, and upstream of still more tasks, including scheduling. As a result, when drilling triggers updates to geological and resource models, those updates then trigger changes to pit optimisation, which trigger changes to pit design, which trigger changes to scheduling. And it is these changes that can singlehandedly clog up the gears of the mine design process.

The issue with traditional data management

With traditional, independent data management, each change has to be repeated in and across each workflow. Take pit and phase optimisation, for example, intended to find the most efficient and profitable pit shape and mining sequence.

With GEOVIA Pit Optimizer, this workflow starts by integrating the envelope optimisation with the mine design, then moves on to aligning the mining schedule to maximise the net present value of the project, evaluating results from various mining scenarios, assessing the risks, and determining the most resilient operational strategy. Results from each step in the pit optimisation workflow inform the next step.

But what if a metal price suddenly goes up or down? A change like that is easy to deal with: just adjust the value of nickel or gold or copper, hit the go button, and re-run the step.

But when the members of a mine planning team are independently managing their own data, often using different software solutions, that change is not automatically communicated to the next engineer or geologist in line. Instead, each must re-do their step in the workflow every time an input changes to ensure the pit shells and reports, schedule and outputs, etc., are accurate and up-to-date. This is both labor-intensive and time-consuming.

There is, however, a proven method to remove the friction between individual components of the design process. It starts with moving to a unified design environment, where all data resides in one place, and everyone works within that same place.

Managing the design becomes a matter of managing inputs

A unified design environment, like the 3DEXPERIENCE platform we use, is organised around parametric design. In this type of design, all inputs and outputs are stored as parameters. For pit optimisation, for example, these parameters include the pit wall slope angle, bench height, metal content, mineral prices, processing costs, scheduling and geotechnical considerations, and so on. More than that, however, the parameters could also be 3D objects, such as pit shells, or even other parameters or formulas.

This parametric organisation in turn compels a linear association or dependency between upstream and downstream tasks, where a change made anywhere by anyone within the unified design environment can (either automatically or by the click of a button) be updated across the workflow and either produce a new optimisation or update an existing one.

In other words, with parametric design, the pit design is aware of the pit shell. If the pit shell is updated, a quick re-run of the pit design will ensure all parameters, including the pit shell change, are applied. In this way, the inputs of each step of the optimisation will actually be the outputs from the prior step.

But the ability to make rapid changes upstream and downstream is not the only benefit of a unified or parametric design environment.

Two additional benefits

What creates a unified design environment is not just the interface or the platform. It’s also the data — for example, the block model used by the geologist will be the same type of block model used by the scheduler — and the metadata, such as who created or updated the design and what comments or objects are associated with it.

Having the metadata is particularly useful. It means that, when I come up with a design, a plan, or a schedule, I can associate tasks, such as peer review, with that output. In that case my colleague will automatically know when it’s time to comment on my work, or to approve it and pass it along to the next level.

Another significant plus is that managing inputs as parameters within a unified design environment also allows me to group inputs together in collections of parameters called scenarios. From there, I can copy a collection, modify the design by just one or multiple parameters, and perform a ‘what if?’ comparison between the scenarios.

How all this works in a unified environment

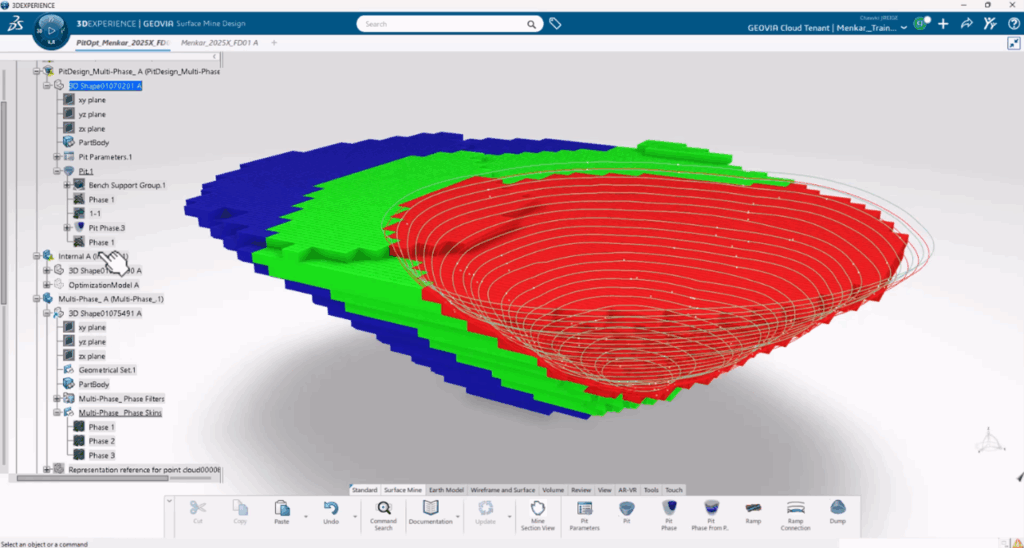

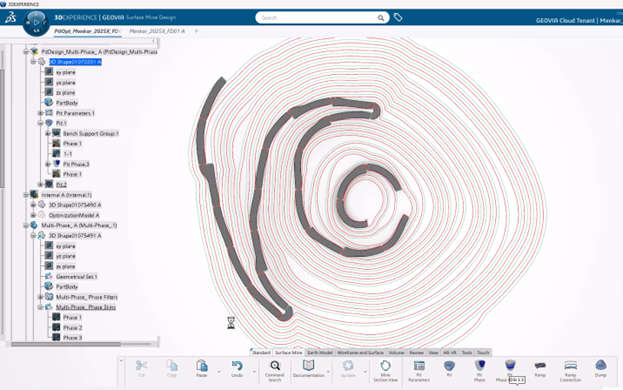

If I’m a planning engineer and I want, say, to generate toes and crests for specific mine designs using GEOVIA Surface Mine Designer, the workflow is more or less as follows.

I first choose a pit shell to which the design should conform, then apply certain parameters, like bench height, berm width, projection angle, etc. I then decide whether I want some (or all) changes, like bench height or angle, to be updated automatically, in which case the design will update itself as soon as I hit okay, or whether I want to make some (or all) changes manually.

Figure 2. Toes and crests of a pit design automatically generated to conform to an optimised pit shell.

If I make that second choice, any non-automatic changes will accumulate until I press the go button. This is particularly helpful if you are making lots of little changes and don’t want the design to update itself every single time: it’s up to you to determine when you are ready to see the cumulative effect of all the changes.

When I decide I’d like to to compare one design scenario to another, I can then drop it into a process composer simulation. Let’s say I want to see what happens to the design if the nickel price per pound changes.

First, I decide how I want that input/parameter to change and how many iterations I want to run: for example, to go up or down by 25 cents in value and to complete 100 iterations. The optimiser will then change that input as specified, execute the workflow with 100 incremental changes, collate the results, and present them to me for analysis at the end. I can compare the design scenarios and select the one that best helps me in my hunt for the optimal pit shape and mining sequence.

In a nutshell

By compelling a linear association and a sequence of tasks, a unified design platform with parametric design as its organising philosophy reduces the friction in the design process.

Because every piece of data in the platform understands every other piece of data, updates based on upstream changes are rapid, which makes it easier for everyone downstream to do their work: strategic mine planners can quickly update a pit optimisation and strategic mine plan whenever the resource model changes, while mine designers can quickly update pit designs based on newly created optimised pit shells. And everyone can experiment by creating scenarios (collections of parameters) and comparing the effects of changes — reducing the time required for design analysis.

Source: AusIMM Bulletin, August 2025

Community is a place for GEOVIA users – from beginners to experts and everyone in between – to get answers to your questions, learn from each other, and network. Join our community to know more:

GEOVIA User Community – Read about industry topics from GEOVIA experts, be the first to know about new product releases and product tips and tricks, and share information and questions with your peers. All industry professionals are welcome to learn, engage, discover and share knowledge to shape a sustainable future of mining.

New member? Create an account, it’s free! Learn more about this community HERE.