Introduction

Manufacturing is more competitive than ever. Companies need to start new production lines faster and with less risk. Virtual Commissioning makes this possible by letting you test and validate your automated systems before installing any physical equipment. You solve problems in the virtual world before they become expensive delays in the real world. This means you can find issues early, optimize performance, and train operators—all in a digital environment.

DELMIA offers a comprehensive solution for Virtual Commissioning that covers everything from robot programming to full factory simulation. You can program and simulate robots, test PLC code virtually, validate entire production lines, and connect your virtual twin to real control models.

With DELMIA Virtual Commissioning, issues can be identified and resolved long before production begins. Manufacturers using this solution have achieved up to 60% reductions in commissioning time, enabling faster production ramp-up, greater confidence, and lower overall costs.

In this blog, discover how DELMIA Virtual Commissioning empowers manufacturers to work smarter, start production faster, and innovate with confidence.

A. What is Virtual Commissioning?

Starting a new production line often means dealing with critical problems: robots not working together, equipment not synchronized, and long delays during setup. Implementing automated systems in industrial environments typically encounters a cascade of challenges throughout the development lifecycle.

Common Commissioning Challenges

- System Interoperability: PLCs, sensors, robots, and MES/SCADA systems may not communicate properly

- Software Bugs or Incomplete Programming: Logic errors in control software or HMI can cause malfunction or unsafe behavior

- Insufficient Testing: Lack of simulated or dry-run testing means issues only surface under real load, risking unplanned downtime

- Safety Concerns: If safety systems aren’t fully commissioned, operators might be exposed to unexpected movements or collisions

- Workflow Disruptions: Frequent stoppages or errors in automation can cause delays, rework, or even damage to materials, requiring manual intervention

These challenges collectively underscore why early virtual validation has become essential for modern industrial implementations. To effectively address these issues, organizations can implement virtual commissioning with detailed virtual twins to simulate both normal operations and exception scenarios before physical construction begins.

Defining Virtual Commissioning

Virtual Commissioning is a simulation-based process that validates and optimizes control systems and automation before physical implementation. It allows for testing and troubleshooting in a virtual environment, reducing risks, costs, and time associated with real-world commissioning.

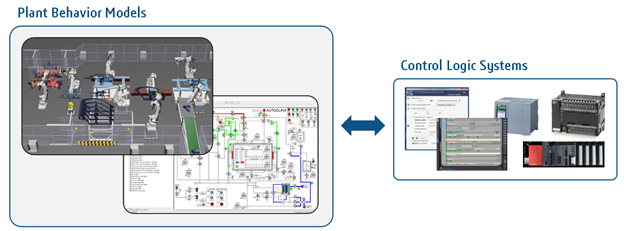

Virtual Commissioning requires three essential elements:

- A Virtual Twin that represents the equipment behavior of the cell/line/plant (robots, conveyors, electromechanical devices)

- The Control Logic, embedded on PLCs

- A Communication Interface between the Virtual Twin and the PLC

The objective is to enable all stakeholders to collaborate efficiently at an early stage of a line implementation project.

Beyond Simple Simulation

Virtual Commissioning is not just simulation—it goes a step further. While simulation represents a broad approach to modeling system behavior, virtual commissioning focuses specifically on testing and validating control programs before actual deployment. Traditional simulation helps manufacturers understand how systems might perform, but lacks the direct connection to real control systems that virtual commissioning provides.

B. DELMIA: A Comprehensive Solution for Virtual Commissioning

Dassault Systèmes offers a comprehensive solution to design, simulate, and optimize the Virtual Twin of automated equipment—from individual machines to complete factories with multiple automated lines. By providing an accurate representation of the real line, this virtual model serves as the source of truth for control system validation, connecting seamlessly to control software and hardware.

With DELMIA, you can simulate robot movements, equipment behavior, and connect your control logic to test real automation sequences. Let’s explore how DELMIA covers the complete Virtual Commissioning workflow.

1. Prepare the Robot Task: Validate Cycle Time, Reachability, and Collision-Free Motions

When implementing a robot on a manufacturing or assembly station, the primary objective is to ensure that the robot’s tasks meet the required specifications while optimizing its path and cycle time. Initially, this is done independently of safety considerations and synchronization with other resources (such as conveyors, jacks, sensors, etc.).

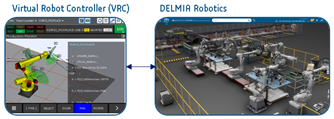

By leveraging the full capabilities of DELMIA Robotics, Robot Programmers can validate and optimize collision-free robot motions for various industrial processes—including spot/arc welding, painting, picking, drilling, and riveting—starting from a 3D model of the product. Once validation is complete, the Robot Programmer can “download” the robot program by translating DELMIA’s language into the native robot language and simulate it in the virtual environment using the real robot controller software (VRC or RCS).

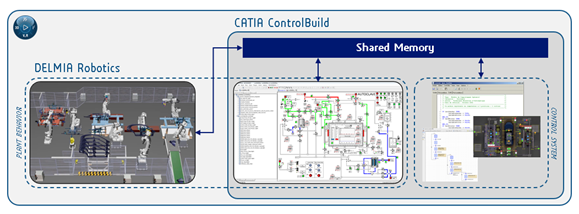

2. Model-In-The-Loop (MiL) Simulation: Connect DELMIA Robotics to ControlBuild

Before running the co-simulation, the Virtual Twin must be completed in two environments:

- In DELMIA: Define sensors, conveyor sections, sources & sinks, and create all mechanical equipment with their kinematics

- In ControlBuild: Define the Plant Behavior model by selecting from an Equipment Library and detailing how electromechanical equipment not commanded by a Robot Controller (conveyors, cylinders, etc.) behave in terms of energy, speed, and other parameters

In MiL, the control model can be developed in ControlBuild using any PLC programming language defined in IEC-61131 (Ladder Diagram, Sequential Function Chart, Structured Text, etc.). This serves as a prototype of the future PLC code (independent of the PLC brand) that defines the process sequence and safety management.

Additionally, an Interactive Virtual User Interface can be designed and used during co-simulation. With this panel, operators can visualize indicators on the process state (sensor detection values, robot state, control program state) and influence it with user commands (push buttons, emergency stops). This is invaluable for testing various scenarios.

The objective of MiL Simulation is twofold:

- Validate and optimize the Virtual Twin of the station/line (including cylinder design, sensor positioning, conveyor speed, safety aspects)

- Validate the concepts of the control program that will manage the manufacturing process

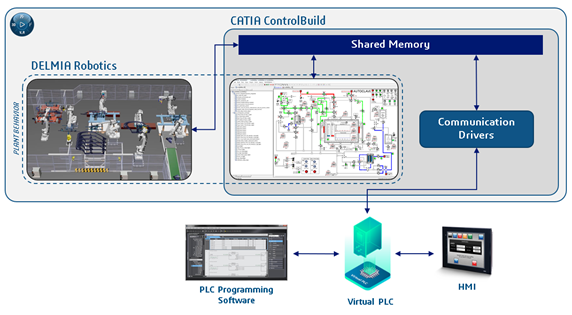

3. Software-In-The-Loop (SiL) Simulation: Connect DELMIA Robotics and ControlBuild to the Virtual PLC

At this stage, the Virtual Twin (including the plant behavior model) is still represented within ControlBuild and DELMIA. However, the control model is now executed and emulated by a Virtual PLC, with the control program being developed within the PLC development framework. We are no longer working with a prototype—the focus shifts to validating and optimizing the final control program.

One key strength of our solution is its vendor agnosticism: we can connect our Virtual Twin to any Virtual PLC. Thanks to ControlBuild drivers specifically developed for this purpose, we can integrate with hardware provider tools from several companies.

The following video demonstrates the same simulation running with two competing solutions: one part using Omron SYSMAC PLC code, and the other using Siemens TIA Portal PLC code emulated in PLCSim Advanced. This clearly showcases our solution’s ability to seamlessly connect to any platform, regardless of the provider.

During SiL validation, the control panel developed for MiL can be reused for software validation. The HMI can also be connected to the Twin to test its development, enabling the combined validation of both the control program and the HMI. This approach allows testing of numerous scenarios and visualization of impacts on Control/HMI, and can even be used for advanced operator training.

4. Hardware-In-The-Loop (HiL): Connect DELMIA Robotics and ControlBuild to the Physical PLC

The final testing method is HiL Simulation, where the Virtual Twin is connected to real hardware components instead of a virtual PLC. This approach is a common and proven Virtual Commissioning practice, as it ensures the hardware operates correctly with the software in real-world conditions. By testing with actual hardware, HiL helps uncover issues that may not be detected in purely software-based simulations.

As with SiL, ControlBuild provides Communication Drivers that enable communication with the hardware through industrial protocols (EtherCAT, OPC-UA, Modbus-TCP, etc.).

However, SiL offers several advantages over HiL:

- Faster Development and Testing: Control algorithms can be tested much more quickly without physical hardware setup or debugging

- Flexibility: Particularly useful when refining control strategies or testing different scenarios

- Scalability: Testing scenarios or running multiple simulations simultaneously is easier, requiring only computational resources rather than physical hardware

C. Benefits of Virtual Commissioning

Manufacturing operations gain remarkable advantages through early virtual validation. Companies implementing this approach report 40-60% reduction in commissioning time and substantial cost savings during factory acceptance testing.

The technology enables comprehensive skills development for operators in a risk-free environment, allowing teams to master complex processes before working with physical equipment. This translates into fewer workplace accidents and improved operational efficiency.

Beyond immediate operational gains, virtual commissioning transforms traditional commissioning by providing relevant data for continuous improvement. For example, a major automotive manufacturer reduced their production line setup time from 8 weeks to just 3 weeks by identifying and resolving integration issues virtually.

In Summary

Virtual Commissioning Delivers:

- Increased production performance

- Reduced on-site testing requirements

- Lower energy consumption

- Less material waste

- Faster time-to-market for new production lines

Virtual Commissioning with DELMIA is not just a testing tool—it’s a strategic approach that transforms how modern manufacturers bring automation systems to life.