In case you missed it, read part 1 and part 2 in this blog series.

Introduction

In our first two articles, we explored the fundamentals of greenfield vs. brownfield steel plants — what they are, how they differ, and when each approach makes sense. But whichever path a steelmaker chooses, the reality is the same: projects are increasingly complex, CAPEX-heavy, and shaped by rising demands for efficiency, decarbonization, and speed to market.

Steel projects today are larger, timelines tighter, and sustainability targets — from hydrogen-based DRI to net-zero blast furnace operations — are reshaping how plants are designed and modernized. Traditional project management methods often struggle, resulting in cost overruns, delays, and downtime.

This is where Digital Twin technology is transforming the game. By creating a virtual steel plant model that connects design, construction, commissioning, and operations, EPCs and steel producers can plan smarter, execute faster, and operate more sustainably across the entire lifecycle.

What Is a Digital Twin in Steel Plants?

A Digital Twin is a dynamic, data-driven representation of a physical asset, process, or system. Unlike static CAD or 3D models, it is continuously updated with real-time data from sensors, automation systems, and process historians throughout the lifecycle.

In steel, a Digital Twin may cover:

- Entire integrated plants (from coke oven batteries to hot strip mills)

- Specific processes (e.g., blast furnace campaigns, BOF tapping, slab casting, or reheating furnaces)

- Logistics and utilities (raw material yards, oxygen/nitrogen plants, power distribution)

The result: a single source of truth where EPC contractors, plant owners, and operators collaborate seamlessly.

The Role of Digital Twins in Greenfield Steel Projects

Greenfield plants provide design freedom but come with multi-billion-dollar CAPEX, 4–7 year timelines, and high permitting complexity. Digital Twins de-risk these projects before the first shovel hits the ground.

Key Benefits in Greenfield Steel Plants

- Virtual Plant Modeling: Optimize site layout, raw material handling (ore, coal, scrap, DRI), and mill logistics before construction.

- 4D/5D BIM Simulation: Link design to construction schedules and CAPEX forecasts, crucial for large integrated plants.

- Modular Construction Planning: Simulate transport and assembly of modules like EAF shells, ladle furnaces, or caster segments.

- Virtual Commissioning: Test and debug automation systems (e.g., BOF control, caster mold monitoring, rolling mill drives) in a simulated environment before start-up.

- Sustainability by Design: Model hydrogen-ready direct reduction, carbon capture units, and renewable-powered utilities from day one.

✅ Result: Greenfield steel plants are commissioned faster, within budget, and aligned with long-term sustainability and competitiveness goals.

The Role of Digital Twins in Brownfield Steel Projects

Brownfield projects leverage existing infrastructure but are fraught with integration risks, space constraints, and downtime challenges. Digital Twins are critical in reducing disruption and maximizing ROI.

Key Benefits in Brownfield Steel Plants

- High-Fidelity 3D Capture: Laser-scan furnaces, casters, and rolling lines to capture as-is conditions before modernization.

- Retrofit Simulation: Validate upgrades (e.g., a new secondary metallurgy station or revamped caster tundish car) for fit and clash detection.

- Shutdown Optimization: Simulate blast furnace relines, caster upgrades, or mill roll changes to minimize downtime.

- Regulatory Compliance: Model gas cleaning, water treatment, or BOF gas recovery systems against emissions norms.

- Lifecycle Integration: Carry lessons from modernization into long-term operations and predictive maintenance.

✅ Result: Brownfield upgrades extend asset life, minimize downtime, and deliver modernization at lower CAPEX — without sacrificing safety or sustainability.

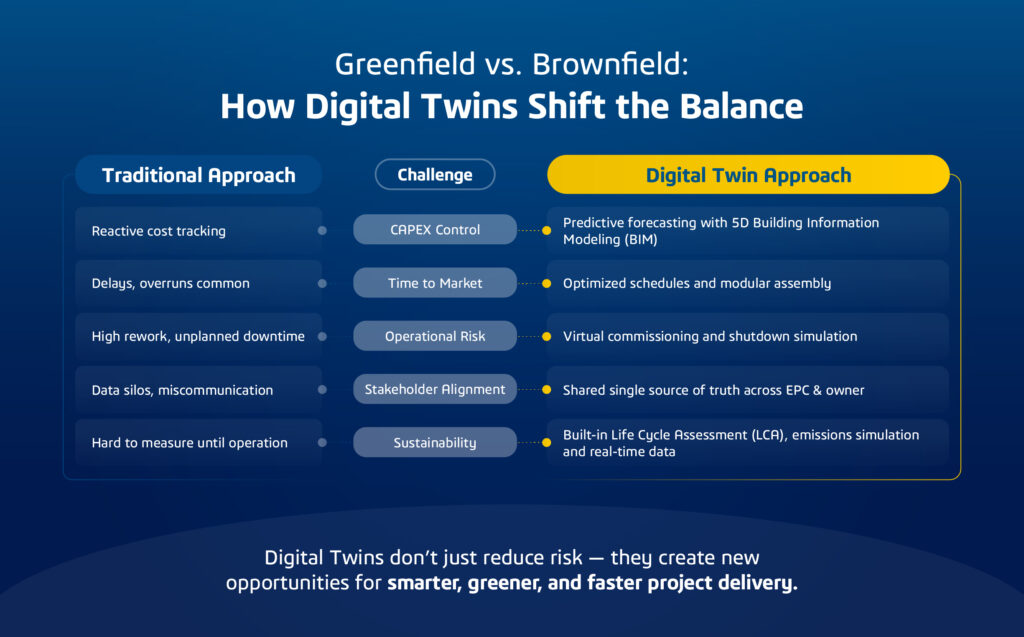

Greenfield vs. Brownfield: How Digital Twins Shift the Balance

Digital Twins don’t just reduce risk — they create new opportunities for smarter, greener, and faster project delivery.

Why Digital Twins Matter for EPCs and Steel Plant Owners

For EPC Contractors

- Connect design, procurement, and construction in one environment.

- Run virtual construction sequences (e.g., mill erection, furnace shell lifting).

- Anticipate supply chain risks — from bulk material delays to labor shortages — before they derail execution.

For Plant Owners

- Faster ramp-up: Virtual commissioning of BOFs, casters, or rolling mills shortens time to full production.

- Operational excellence: Real-time monitoring of energy intensity, yield, and emissions.

- Predictive maintenance: Anticipate blast furnace campaign issues, caster mold wear, or mill drive failures before unplanned downtime.

- Sustainability tracking: Continuously monitor CO₂ emissions and align with net-zero steel roadmaps.

Together, EPCs and owners gain the most when they collaborate on a shared digital backbone, ensuring transparency, faster decision-making, and continuous improvement across projects.

How Digital Twins Drive Sustainable Steelmaking

As global steelmakers commit to 50% CO₂ reduction by 2030 and net-zero by 2050, Digital Twins are becoming indispensable:

- Lifecycle Assessment (LCA): Quantify emissions from raw material yard to finished coil at the design stage.

- Virtual Process Optimization: Simulate BOF slag chemistry, DRI charging in EAFs, or rolling mill reheating to cut energy intensity.

- Extend Asset Life: Instead of building new, optimize retrofits to keep furnaces, casters, and mills competitive longer.

By bridging economic performance and environmental responsibility, Digital Twins give steelmakers the ability to achieve ESG compliance without compromising throughput.

Case Examples: Digital Twins in Action

- Greenfield Example – Hydrogen-DRI in Northern Europe

A European steelmaker is building a hydrogen-based DRI plant with EAFs on a new greenfield site. A Digital Twin was deployed from day one to simulate raw material logistics, design modular furnace shells, and virtually commission the meltshop. This cut expected ramp-up time by 20% and gave investors confidence in the project’s decarbonization targets. - Brownfield Example – Caster Revamp in India

An Indian integrated steel producer used Digital Twins to plan a continuous caster upgrade at an operating plant. High-fidelity 3D scanning mapped the existing layout, while simulation tools modeled tundish car changes and mold cooling upgrades. The result: downtime during the shutdown was cut by 30%, and output quality improved without adding new CAPEX-intensive infrastructure.

These examples illustrate how Digital Twins de-risk both paths: clean-slate sustainability for greenfields, and fast, efficient modernization for brownfields.

Conclusion

Whether building a greenfield hydrogen-ready DRI complex or upgrading a brownfield blast furnace and caster line, steel projects face rising complexity, costs, and sustainability pressures.

Digital Twins are the new foundation for competitiveness:

- In greenfields, they accelerate design, reduce CAPEX risks, and embed sustainability from the start.

- In brownfields, they minimize disruption, extend asset life, and de-risk modernization.

For EPCs and plant owners navigating steel factory modernization, EPC execution, and decarbonization goals, the message is clear:

📘 Digital mastery is the new competitive advantage.

Download our free ebook: Greenfield to Brownfield: Reinventing Steel Plants with Digital Twins to learn how to deliver faster, greener, and more resilient projects and visit the future of metals and steel manufacturing.