Any robot programmer with time on the job may have experienced implementing fixes and workarounds on the shop floor. This is primarily done because robot programming is not part of the initial design phase. In fact, it leaves robot programmers with a challenge. This leads to increased costs as production cycles expand. Changes are then made, often without knowledge of the shop floor impacts.

Increased Complexity

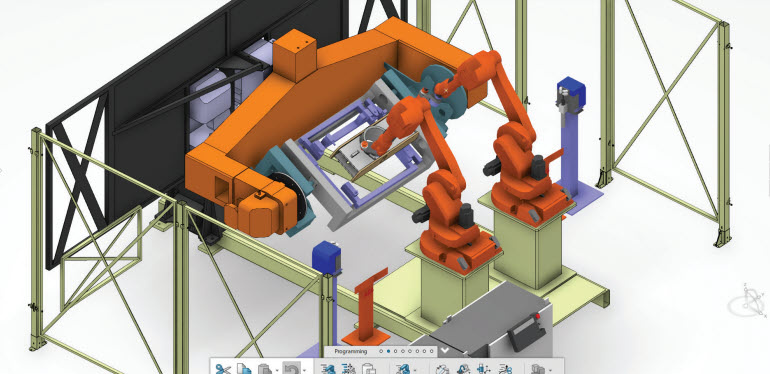

Add to that scenario, increased complexity. This is where some of the latest developments in robot technology can make it extremely difficult for robot programmers, especially when there are multiple robot arms. Programming multiple robot arm systems is extremely challenging on the shop floor. It increases the amount of risk to the product, tooling, and project schedule.

Speed, Cost Reduction and Accuracy

Robotic manufacturing processes, with their clear advantages of speed, cost reduction and accuracy, are being widely adopted for a broad range of production needs. Robot programmers, however, can find it challenging to deliver material handling, arc welding, spot welding, painting, or drill and riveting programs that work with certainty on the first run. Because robot programming is not part of the design phase, they are forced to implement fixes and workarounds on the shop floor. Costs escalate as production cycles expand and changes are made without knowledge of the shop floor impacts.

Perform Predictably the First Time

However, DELMIA Robotics software on the Dassault Systèmes 3DEXPERIENCE® platform can deliver high-quality, collision-free programs in the native robot language with minimal intervention on the shop floor. In the virtual world, programmers and designers work in concert to create the most productive tooling operations and robot cycle times. Programming can move ahead independently without interrupting production, and robot programs perform predictably the first time. Costs of programming and production are significantly reduced, and products move to market more quickly.

DELMIA Robotics offers a clear path to more productive workcells and product lines. Separating programming from production, and delivering collision-free, first-time-right programs to the shop floor, keeps production lines rolling and moves products to market faster. Programmers leverage the 3DEXPERIENCE platform and a host of productivity tools to program high-quality workcells more quickly. Real-time visual collaboration with design and manufacturing engineers simplifies change management and keeps process planning on track. The ability to modify and reuse successful programs saves massive amounts of programming time. DELMIA Robotics offers benefits that can make manufacturers more productive and profitable.

To Learn More

Discover more on the cost-saving benefits of DELMIA Robotics in our whitepaper: 3D Robot Programming Reduces Costs and Streamlines Production – Dassault Systèmes (3ds.com)