Introduction

When a steel producer considers increasing crude steel output, modernizing rolling capacity, or entering new regional markets, leadership faces a fundamental decision: invest in a new greenfield steel plant or upgrade an existing brownfield steel plant.

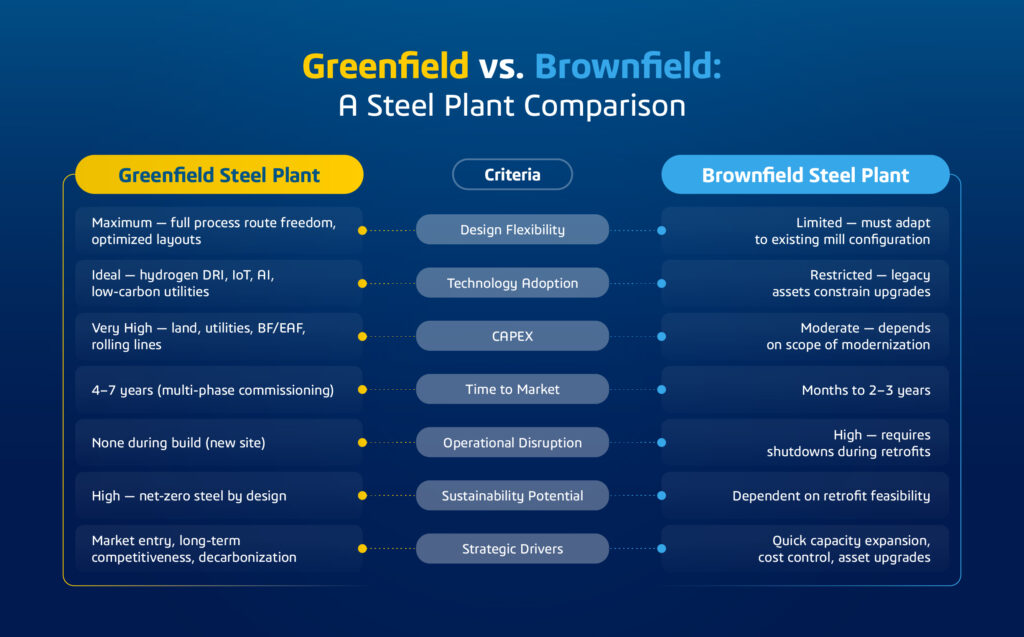

Both paths are viable strategies in a capital-intensive industry, but they differ significantly in CAPEX, construction timelines, production flexibility, energy efficiency, and decarbonization potential. For EPC partners, plant owners, and steel executives, understanding these trade-offs is critical to balancing competitiveness, cost, and sustainability.

This article defines greenfield and brownfield steel plants, explores their characteristics, compares their advantages, and illustrates both approaches with real-world case studies.

What Is a Greenfield Steel Plant?

A greenfield plant is a new steel facility built on undeveloped land. This allows the design of integrated production from ironmaking to finishing lines, without the constraints of legacy infrastructure.

Key Characteristics of Greenfield Steel Plants

- Maximum Design Freedom

Engineers can design optimized blast furnace–basic oxygen furnace (BF-BOF) or electric arc furnace (EAF) routes, install state-of-the-art rolling mills, and configure logistics for raw material handling (iron ore, coking coal, scrap, DRI) without compromises. - Integration of Advanced Steel Technologies

From the outset, plants can embed hydrogen-ready direct reduction units, low-carbon power systems, and advanced automation (IoT-enabled ladle tracking, AI-driven casting controls, or digital twin meltshop simulations). Sustainability goals like near-net-zero emissions can be built into the facility from day one. - High CAPEX

Greenfield steel plants require billions in upfront investment. Costs cover land acquisition, permitting, raw material yard development, utilities (power, water, oxygen plants), coke ovens, pellet plants, and full downstream rolling and finishing lines. - Longer Time to Market

Construction, commissioning, and ramp-up can span 4–7 years, depending on project scale and permitting requirements. - Strategic Use Cases

Greenfield projects are common when steelmakers:- Enter a new market or geography.

- Require very large capacity expansions.

- Target low-carbon or hydrogen-based steel production.

- Build for long-term global competitiveness.

What Is a Brownfield Steel Plant?

A brownfield project involves upgrading, modernizing, or expanding an existing steel facility. This leverages existing assets such as power plants, coke ovens, rail spurs, and workforce skills — making it faster and less capital-intensive.

Key Characteristics of Brownfield Steel Plants

- Capital Efficiency

Brownfield expansions often cost a fraction of greenfields since land, utilities, and logistics are already in place. A new hot strip mill, EAF line, or secondary metallurgy facility can be integrated without full site build-out. - Faster Execution

Revamp or debottlenecking projects — such as a blast furnace relining, caster upgrade, or mill automation — can be completed in months to a few years, much faster than a greenfield. - Integration Challenges

Retrofitting a modern EAF or advanced emissions-control system into decades-old infrastructure can be complex. Space constraints, aging utility lines, and outdated IT/OT systems may limit efficiency gains. - Operational Disruption

Upgrades often need to be carried out while the mill is still producing steel. Furnace shutdowns, safety risks, and production losses must be carefully managed with tight scheduling. - Strategic Use Cases

Brownfield projects make sense when:- Steelmakers need rapid capacity additions.

- Budgets don’t allow multi-billion-dollar new builds.

- The location offers strong strategic advantages (close to raw materials, ports, or skilled labor).

- The goal is asset life extension or modernization to meet environmental compliance.

Greenfield vs. Brownfield: A Steel Plant Comparison

Why These Differences Matter in Steel

- Cost vs. Risk: Greenfield steel plants demand high upfront CAPEX but can deliver world-class efficiency for decades. Brownfield upgrades are cheaper and quicker but carry integration and downtime risks.

- Speed: When demand surges, brownfield expansions enable rapid response, while greenfields require long-term planning.

- Decarbonization: For producers under pressure to cut CO₂, greenfield hydrogen-ready plants offer a clean start. Brownfields require complex retrofits of blast furnaces, gas recovery systems, and carbon capture units.

Digitalization in Greenfield and Brownfield Steel Plants

Digital technologies now define project success:

- Greenfield Plants: Use of digital twin steel plant models, 4D/5D BIM, and modular construction enables EPC partners to forecast CAPEX, simulate casting/rolling sequences, and shorten commissioning timelines. Plants can be “born digital,” ensuring predictive maintenance, energy optimization, and sustainability from day one.

- Brownfield Plants: 3D laser scanning, digital twins of existing assets, and predictive analytics are essential to plan revamps. These tools reduce risks by mapping existing constraints, forecasting shutdown durations, and minimizing production losses.

For both, data-driven EPC execution improves collaboration across disciplines, reduces rework, and creates smarter, more resilient plants.

Case Studies: Greenfield and Brownfield in Action

- Greenfield Example – Europe’s Push for Green Steel

A leading European steelmaker recently announced a €2 billion greenfield hydrogen-based DRI (Direct Reduced Iron) plant alongside electric arc furnaces. By choosing a greenfield site, the company avoided the constraints of retrofitting blast furnaces and instead designed a facility optimized for renewable hydrogen input, digital twin control systems, and low-carbon power infrastructure. While the CAPEX and timeline are significant, the payoff is positioning themselves as a first mover in the global green steel market. - Brownfield Example – India’s Rapid Capacity Expansion

In contrast, a major Indian steel producer expanded output through a brownfield electric arc furnace and hot strip mill revamp at an existing integrated plant. The decision allowed the company to add 3 million tonnes of crude steel capacity in under two years, leveraging existing utilities, coke ovens, and logistics infrastructure. By using 3D scanning and predictive maintenance tools, the EPC team minimized downtime, ensuring the plant could continue meeting domestic demand while ramping up capacity at speed.

These examples highlight the strategic drivers behind each choice: greenfields enable clean-slate decarbonization, while brownfields deliver faster, more cost-efficient growth in high-demand markets.

Conclusion

For the steel industry, the choice between greenfield and brownfield projects is not just a construction decision — it’s a strategic move that shapes competitiveness for decades.

- Greenfield = freedom, cutting-edge design, high CAPEX, and long-term sustainability.

- Brownfield = speed, capital efficiency, and modernization within constraints.

Both paths will play a critical role as the steel sector transitions toward low-carbon production, digital transformation, and global competitiveness as part of the future of metals and steel manufacturing.