Revolutionizing Manufacturing with Agile AI-Driven Production

Manufacturing is reaching a breaking point. Rigid production and logistics systems slow setup, ramp-up and scaling, while deterministic automation struggles with real-world change, from new variants to unplanned constraints. The future is agile, software-defined production built on modular autonomous equipment, proven virtually and deployed with confidence.

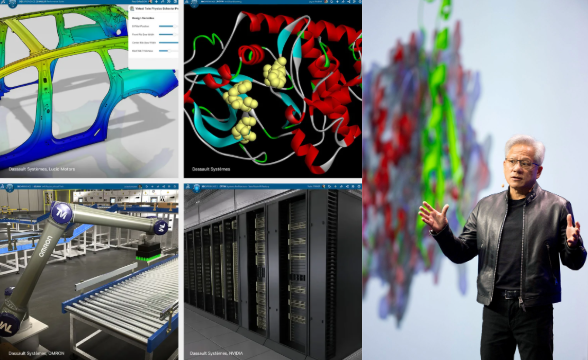

Dassault Systèmes and NVIDIA are building the industrial AI foundation to make that future real. DELMIA contributes the virtual twin of production systems, a semantically rich model of production that connects design intent to real-world execution across engineering, manufacturing and supply chain. NVIDIA contributes physical AI and accelerated computing to simulate robotics-grade physics and perception at scale. Together, we can virtualize and orchestrate autonomous production systems so manufacturers can prove changes virtually and then make them real faster, with less risk and rework.

This collaboration establishes a shared industrial AI architecture that grounds artificial intelligence in the laws of physics and validated scientific knowledge. The integration of NVIDIA Omniverse physical AI libraries into the DELMIA Virtual Twin of global production systems represents a major step forward. It allows manufacturers to design, simulate and operate complex systems with a new level of confidence and precision. Not just incremental improvements; this partnership establishes a mission-critical system of record for industrial AI that powers a new way of working.

Virtual Twins: The Cornerstone of Modern Manufacturing

For years, manufacturers have optimized production lines in the physical world. While effective, this approach is often slow, resource-intensive and constrained by the cost of experimentation in live operations. Virtual twin technology changes this dynamic. A virtual twin is a science-based model of a system that goes beyond visualization, enabling realistic validation of how operations should run before changes are made in the real world.

DELMIA empowers companies to create comprehensive virtual twins of their entire operational ecosystem. This includes everything from individual machines and robotic workcells to full factory floor layouts and global supply chains. Within this virtual environment, manufacturers can:

- Simulate and validate production processes before a single piece of equipment is installed.

- Optimize workflows for maximum throughput and efficiency.

- Identify potential bottlenecks and safety hazards without disrupting ongoing operations.

- Train operators and maintenance crews in a risk-free setting.

The virtual twin orchestrates design, engineering, production and supply chain in one environment so decisions can be tested, trusted and reused. This capability alone delivers significant value, but its impact grows when combined with physical AI.

Integrating AI for Autonomous Production

The partnership with NVIDIA brings physical AI into DELMIA virtual twins. NVIDIA Omniverse provides a platform for developing and operating 3D simulations and industrial digitalization applications using OpenUSD-based interoperability. Combined with DELMIA’s production semantics, manufacturers can test autonomous behavior in realistic conditions before deployment.

This is the shift from “mirroring reality” to “proving change.” AI models accelerated by NVIDIA computing can evaluate scenarios across production constraints, resources and variability. They can help teams reduce commissioning surprises, improve flow and validate how production should respond to change, from new variants to disruptions.

The result is the emergence of software-defined production systems. These are factories and operations where decisions remain human-led, but are continuously supported by AI that recommends, tests and validates options in the virtual twin before changes are deployed. This creates a feedback loop where the virtual world is used to validate better outcomes for the real world.

A Practical Application: The OMRON Collaboration with DELMIA & NVIDIA Drive Real-World Success

To understand the real-world impact of this technology, consider the collaboration with OMRON, a global leader in industrial automation. OMRON recognizes that addressing the growing complexity of modern manufacturing requires a move toward fully autonomous and digitally validated production systems.

By combining DELMIA’s Virtual Twin of Production Systems, NVIDIA physical AI, and OMRON automation technologies, manufacturers can move from design to deployment with greater confidence. When a manufacturer introduces a new product variant or packaging change, automation often fails in small but costly ways, such as automation-grasping reliability, orientation on conveyors or downstream flow stability. Instead of trial-and-error changes on the line, teams can validate process logic, layout constraints and operating rules in the DELMIA virtual twin, then simulate realistic robot and material behavior using NVIDIA’s AI before deployment. The result is faster adaptation and less physical rework.

The Top 3 Broader Impacts on Manufacturing

This fusion of virtual twin technology and industrial AI has far-reaching implications for the entire manufacturing sector inlcuding:

- Unlocking New Efficiencies: Software-defined production systems can continuously identify operational improvements that are difficult to see through manual oversight alone, improving throughput, uptime and overall performance while reducing avoidable losses.

- Advancing Sustainability Goals: By simulating processes in the virtual world, companies can minimize physical prototyping and reduce waste. AI-driven optimization within the DELMIA virtual twin helps manufacturers fine-tune their operations to consume less energy and use fewer raw materials, directly contributing to their sustainability commitments.

- Fostering Continuous Innovation: When the risk and cost associated with testing new ideas are lowered, innovation flourishes. Manufacturers can experiment with novel factory layouts, new automation strategies and different production workflows within the safety of the virtual twin. This agility allows them to adapt quickly to changing market demands and stay ahead of the competition.

The partnership between Dassault Systèmes and NVIDIA is about more than just combining two powerful technologies. It’s about establishing a new, scientifically-validated foundation for industrial AI. By integrating NVIDIA’s physical AI libraries into DELMIA, we are empowering manufacturers to build the autonomous, efficient and sustainable factories of tomorrow, today.