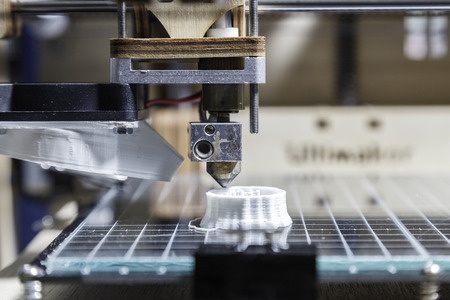

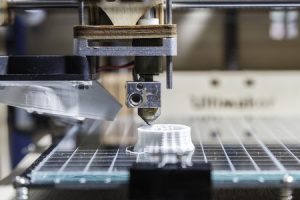

With 3D printing becoming more versatile and less expensive, we’re starting to see more and more companies take advantage of the technology. While additive manufacturing software has been around for decades, advancements in 3D printing technology are creating a number of significant changes in the industry. Here are five of the most interesting.

1. More Custom-Built Products

The most obvious advantage of 3D printing is that it allows you to make easily a variety of different designs with the same machine. Often working in combination with 3D scanning technology, we’re starting to see businesses market completely customized products using 3D printing. For example, 3D printing is being used to create prosthetic limbs that are less expensive and conform entirely to the remaining limb.

In the future, we may see more companies offering custom options for products that traditionally don’t have them. You could provide a pair of earbuds with cushions printed to fit perfectly in the user’s ear, for instance, or you could create shoes that conform exactly to the shape of the foot.

2. New Design Possibilities

Every method of manufacturing has its limitations, but when it comes to design, additive manufacturing has fewer than most. While most obstacles can be overcome by combining different manufacturing techniques or splitting the design into multiple parts, 3D printing allows industrial designers to pursue concepts that wouldn’t otherwise be possible.

Objects with complex interior structures can be created from a single piece, and moving parts can be built already in place, without the need to attach them later. Even large objects can be created with 3D printing. One company is already taking this to the extreme, building entire houses using the technology.

3. Easy Replacement Parts

As 3D printing takes hold in the consumer market, more machines may be designed with 3D-printed parts. This has additional implications beyond the previously stated advantages. Most notably, a 3D printed part can be replaced with any compatible 3D printer. Products, especially those designed for industrial use, could be shipped with digital blueprints of different components. That would allow the end user to create replacement parts themselves rather than ordering them from the manufacturer.

4. More Recycled Materials

3D printers can accept recycled material easily, provided it’s properly prepared. With machines that convert waste plastic into 3D printing material already on the market, one of the main obstacles to 3D printing is being removed. Rather than ordering more specialized plastic, you can break down ordinary waste from things like milk jugs to create your own material. With the adoption of 3D printing technology, many companies could use recycled plastics for most or even all of their raw materials.

5. Digital Piracy Enters the Real World

One of the more concerning aspects of 3D printing is the possibility of copyright infringement. Digital films are illegally leaked and downloaded on the Internet, and the blueprints for a product could be as well. This would allow less scrupulous individuals to make the item entirely themselves rather than paying its creator for the blueprints. Even objects not made through 3D printing are subject to abuse, as a simple 3D scanner can be used to create a digital blueprint of the physical object.

In fact, these kinds of copyright violations are already happening, and so far companies are having trouble finding any way of stopping them. In the future, websites that allow users to share 3D blueprints may employ a more complex version of the content ID systems found on video sites like YouTube. The system could try to match uploaded blueprints with known objects, removing any that violate copyright. Of course, this requires manufacturers to cooperate, providing blueprints for their products for comparison.

Even then, any item without a digital blueprint would remain subject to abuse, and minor alterations could be made to disguise pirated blueprints. It’s a tall order for those trying to protect their copyright, and it’s an issue that’s not likely to be solved anytime soon.

In the meantime, the rise of 3D printer technology is exciting, and there’s still a lot to learn. It will be interesting to continue to watch and see what kinds of things can be accomplished via 3D printing.