Across industries such as automotive, aerospace, marine, industrial equipment, and high-tech sectors, Failure Modes and Effects Analysis (FMEA) is widely recognized as a key method for identifying potential risks and issues during product development.

FMEA has become a standard tool for risk assessment and mitigation, offering a structured framework with clearly defined steps to tackle development-related challenges. However, despite its systematic nature, the FMEA process has certain limitations and gaps that can affect the overall efficiency of the development cycle.

FMEA is generally categorized into two main types: Design FMEA (DFMEA) and Process FMEA (PFMEA). Additionally, other variants exist, such as System FMEA, Functional FMEA, Software FMEA, and Service FMEA. This write-up focuses specifically on DFMEA.

DFMEA is used to detect potential failure modes within a product’s design—well before it reaches the manufacturing stage or the end customer. It helps evaluate components, assemblies, and sub-systems to understand how design-related issues might lead to failure, thereby supporting early improvements in reliability and performance.

This blog delves into how combining SysML-driven Model-Based Systems Engineering (MBSE) with FMEA can improve early detection and resolution of design challenges. By leveraging the strengths of both approaches, organizations can accelerate product development, reduce costs, and enhance quality and efficiency.

What is FMEA?

FMEA (Failure Modes and Effects Analysis) is a structured, systematic approach used to identify potential failures in a product, process, or system and evaluate their possible impact. The goal is to prioritize risks and take corrective actions to prevent or reduce the chances of those failures occurring.

How Does FMEA Work?

- Identify the scope: Define the product, process, or system to be analyzed.

- List potential failure modes: Determine the different ways each component or step could fail.

- Analyze effects: Assess the consequences of each failure mode on the system or end user.

- Determine causes: Identify the root causes of each failure mode.

- Assign risk scores: Rate the severity, likelihood of occurrence, and ability to detect each failure (usually on a scale of 1 to 10).

- Calculate the Risk Priority Number (RPN) /AP (Action Priority): Multiply severity × occurrence × detection to prioritize risks.

- Take corrective actions: Recommend and implement actions to eliminate or reduce high-priority risks.

- Review and update: Re-evaluate after changes to ensure risks are managed effectively.

Model-Based Systems Engineering (MBSE) is a modern approach to systems engineering that uses models rather than traditional documents as the primary means of capturing, analyzing, and communicating system design and requirements. It helps improve understanding, traceability, and consistency throughout the development lifecycle.

SysML (Systems Modeling Language) is a standardized modeling language specifically designed for systems engineering. It extends a subset of UML (Unified Modeling Language) and provides graphical notations to represent system requirements, behaviors, structures, and parametrics.

A SysML-based Model-Based Systems Engineering (MBSE) process uses SysML as the primary language to support the end-to-end development of complex systems. It provides a structured way to capture, analyze, and validate system requirements, design, behavior, and constraints—all within a unified model.

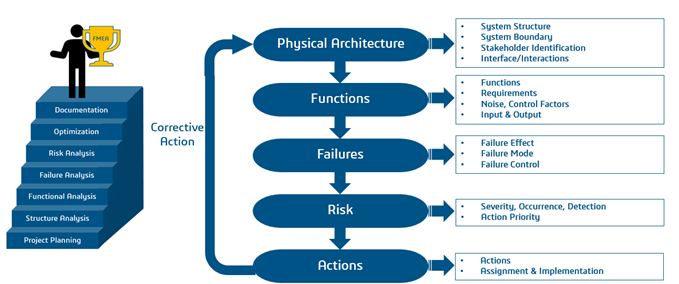

AIAG-VDA FMEA process

The AIAG-VDA FMEA (Failure Modes and Effects Analysis) process is a structured, collaborative approach to identifying and mitigating potential failures in design or process. It integrates best practices from both AIAG and VDA to improve risk assessment, emphasizing a 7-step methodology for consistency and effectiveness.

Observations on DFEMA process based on AIAG-VDA:

- VDA DFMEA begins with the physical design, followed by identifying and addressing functional issues in system components.

- Detecting problems during the design phase often reveals interdependencies or cross-disciplinary concerns too late, resulting in significant rework.

- Decisions made during the concept or preliminary design phase are not validated until the detailed DFMEA stage, requiring extensive corrective efforts.

- The process typically involves several iterations before arriving at an optimal solution.

- DFMEA has traditionally emphasized mechanical systems, with less focus on disciplines such as electrical, electronics, and software.

- As a result, interdisciplinary challenges in these areas often go unaddressed in the early stages.

- The AIAG-VDA DFMEA methodology tends to be more effective for simpler systems and may fall short when applied to complex, integrated systems.

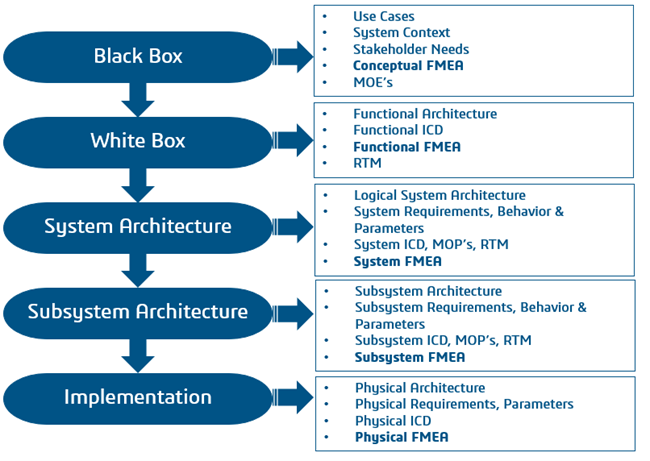

SysML & MBSE-based FMEA process

The SysML and MBSE approach to FMEA integrates failure analysis directly into system models. Instead of relying on static documents, this method uses system architecture models to trace functions, interfaces, and dependencies—enabling earlier and more accurate identification of failure modes. It supports interdisciplinary collaboration and is especially effective for analyzing complex systems with mechanical, electrical, and software interactions.

Moreover, it encourages performing FMEA at every stage of product development, during concept studies like black box and white box analysis like conceptual FMEA and functional FMEA. Also, FMEA is performed at every stage of product development, like system, subsystem, and physical architecture phases.

Observations on DFEMA process based on SySML

- Early Issue Detection: FMEA is initiated during the concept phase, enabling identification of risks early in the development cycle.

- Continuous Application Across Development Stages: FMEA is conducted throughout the product lifecycle, including concept, preliminary, and detailed design phases.

- Multi-Perspective Risk Analysis: Employing black-box, white-box, functional, and logical analyses help uncover a broader range of potential issues and risks.

- Improved Visibility of Interdependencies: Facilitates recognition of interdependency and interdisciplinary risks among stakeholders and across domains such as mechanical, electrical, and software.

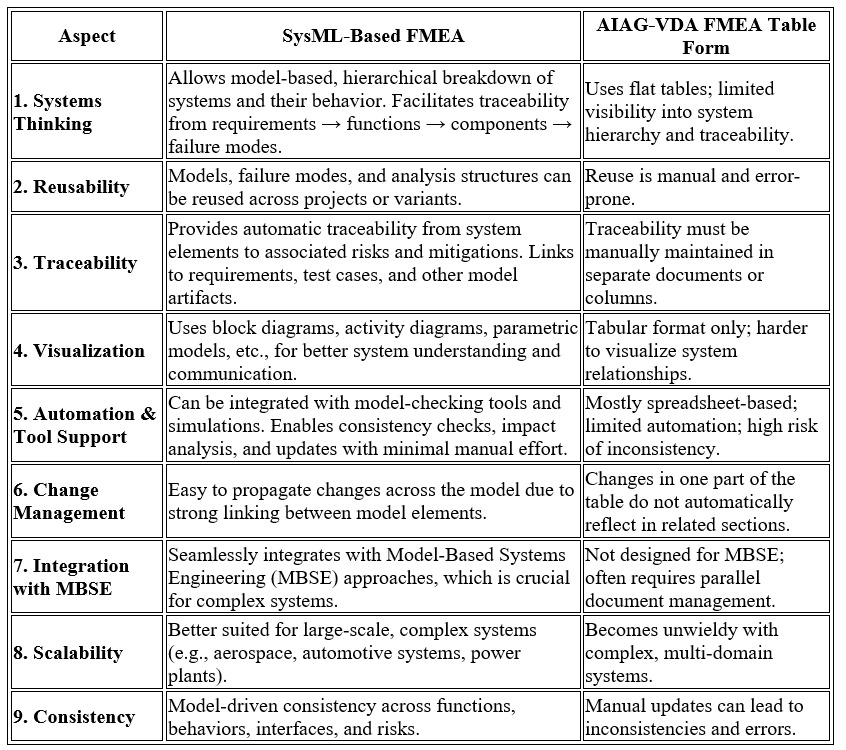

Apart from the above-mentioned points SysML-based FMEA offers several advantages over the traditional AIAG-VDA FMEA table form, particularly in systems engineering and complex product development. Here’s a comparison focusing on the advantages of SysML-based FMEA:

When to Use SysML-Based FMEA?

- In complex systems engineering projects (like aerospace, automotive, energy systems).

- When a high degree of traceability and integration is required.

- When frequent design changes or variants are involved.

When AIAG-VDA Table Might Still Be Suitable?

- For standard, less complex products.

- In organizations where MBSE is not adopted.

- When team members are more comfortable with traditional Excel or tabular formats.

Author:

Kiran JACOB, Industry Process Consultant Senior Manager, Dassault Systèmes India