In a world where transportation products can consist of thousands of unique parts, Brazilian bus manufacturer Marcopolo turned to the 3DEXPERIENCE platform from Dassault Systèmes to unlock new levels of efficiency and collaboration. With CATIA and ENOVIA at the core of its digital engineering ecosystem, Marcopolo transformed how it designs, validates, and brings complex vehicles to market, dramatically shortening development cycles and centralizing product data across global teams.

Centralizing Complexity: A Unified Digital Backbone for Mobility Design

Marcopolo is a global leader in mobility solutions, producing buses, trams and customized transport vehicles for customers in over 140 countries, with engineering teams that generate around 600 new parts daily. Each double-decker bus, for example, includes up to 5,000 unique components engineered and assembled across disciplines.

This scale of complexity demanded a single, integrated design and data environment. Previously, separate teams worked in silos, using disparate design tools that only came together at the physical prototyping stage, leading to costly rework and delays.

Marcopolo chose the 3DEXPERIENCE platform, continuing its long history with Dassault Systèmes tools (from SOLIDWORKS to CATIA), to centralize product data, design in a unified workspace, and manage part information with ENOVIA.

Design Anywhere, Validate Everywhere: CATIA and ENOVIA in Action

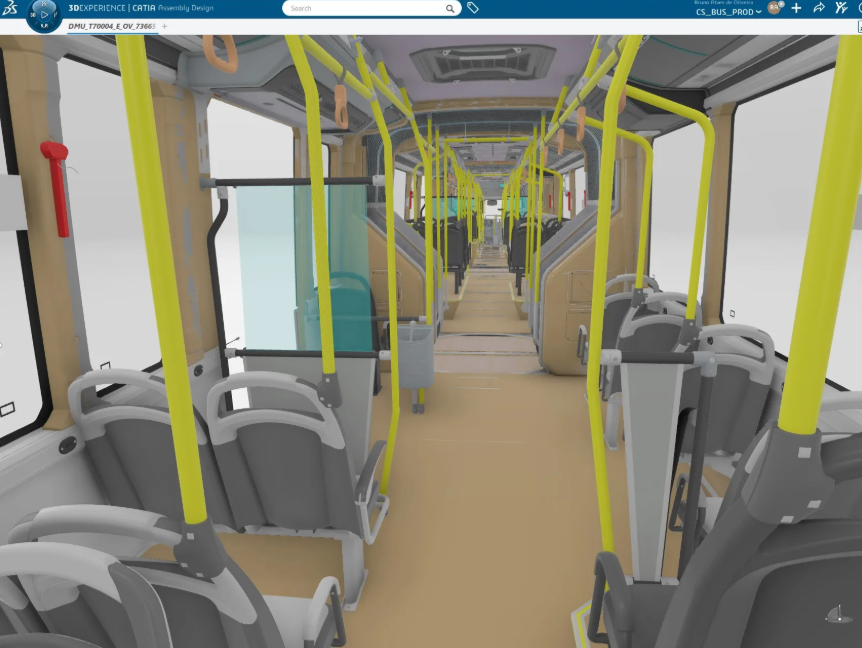

At the heart of Marcopolo’s transformation is CATIA, a best-of-breed design solution that enables engineers to work on parts in the context of the entire vehicle, not in isolation. This shift has breaks down design barriers and gives engineers a holistic view of assemblies early in the development process.

CATIA is an incredibly powerful design tool. It can handle entire assemblies, which means our engineers can now work on parts in the context of the entire vehicle[…] by Tiago Mendes da Silva, Engineering Coordinator, Marcopolo

Complemented by ENOVIA’s digital mock-up (DMU) and collaborative data management, the platform ensures that when a change is made, it’s reflected across the design in real time, empowering multidisciplinary teams to jointly review and validate complex products before physical prototypes are ever built.

Collaboration at Scale: Reducing Errors and Accelerating Time to Market

The unified environment enabled by 3DEXPERIENCE deliveres measurable improvements:

- Four times faster engineering workflows due to centralized data.

- 30% fewer engineering errors through early digital validation.

- 50% reduction in prototype production time, accelerating the launch of new models.

- The Generation 8 buses, developed entirely on the platform, reached market one year faster than previous generation vehicles.

By enabling stakeholders to visualize, analyze, and interact with accurate 3D representations early in development, even when using virtual reality tools, Marcopolo moves critical decisions earlier in the development process, reducing rework and cost before manufacturing begins.

Digital Transformation Beyond Engineering: Toward Smart Manufacturing

Marcopolo’s adoption of 3DEXPERIENCE extends beyond design and engineering. The platform also is being deployed at manufacturing facilities, where tablets and strategic displays give production teams real-time access to design data.

Looking ahead, the company plans to leverage DELMIA to automate processes and simulate shop-floor operations, including programming and optimizing nearly 80 industrial robots, further tightening the feedback loop between engineering and production.

In parallel, Marcopolo is building what it believes will be the industry’s first comprehensive product configurator, enabling customers to personalize vehicles online from millions of possible combinations, while accelerating internal development workflows.

Conclusion

For Marcopolo, the 3DEXPERIENCE platform, with CATIA and ENOVIA at its core, is more than software; it’s a digital backbone that supports complexity, enhances collaboration, and accelerates innovation across global operations. By bringing design, data and collaboration together in a single environment, Marcopolo is redefining what efficient, high-quality mobility development looks like.

FAQ

- How has Marcopolo benefited from CATIA on the 3DEXPERIENCE platform?

Marcopolo uses CATIA to design complete bus assemblies and manage complex parts in context, improving collaboration and reducing engineering errors.

- What role does ENOVIA play in Marcopolo’s digital ecosystem?

ENOVIA centralizes product data as a single source of truth and synchronizes updates across teams in real time.

- How has centralized data improved Marcopolo’s engineering processes?

Centralized data has reduced prototype production time by 50%, cut engineering errors by 30%, and enabled simultaneous multi-project development.

- What impact has 3DEXPERIENCE had on time to market?

Generation 8 buses developed entirely on the platform launched one year faster than previous models thanks to integrated workflows.

- How is Marcopolo extending the use of 3DEXPERIENCE beyond design?

The company plans to use DELMIA for shop-floor automation and is building a digital product configurator to transform customer customization and development workflows.