An Ambitious Bipropellant Engine Project

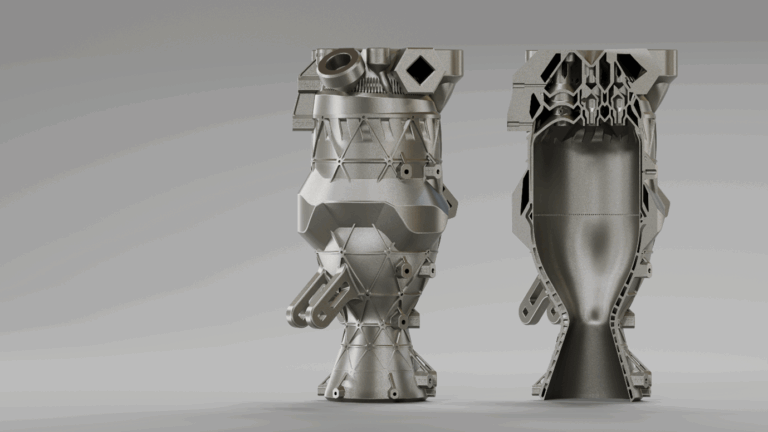

Propulse NTNU, a student organization from the Norwegian University of Science and Technology (NTNU), is pushing the boundaries of aerospace innovation with its self-developed bipropellant liquid engine.

Established in 2018, this team of 85 members is working diligently each year to create a new rocket capable of reaching space, and their current project is undoubtedly their most ambitious. With their bipropellant test engine, which is set to launch from Norwegian soil in the late summer, they aim to reach new heights never achieved before by the team.

This engine is designed to deliver 2.5 kilonewtons of thrust using ethanol and liquid oxygen. It incorporates advanced features like thrust vector control and two-pass regenerative cooling. And its cooling channels are a testament to the team’s engineering prowess, being intricately designed for rocket precision and efficiency.

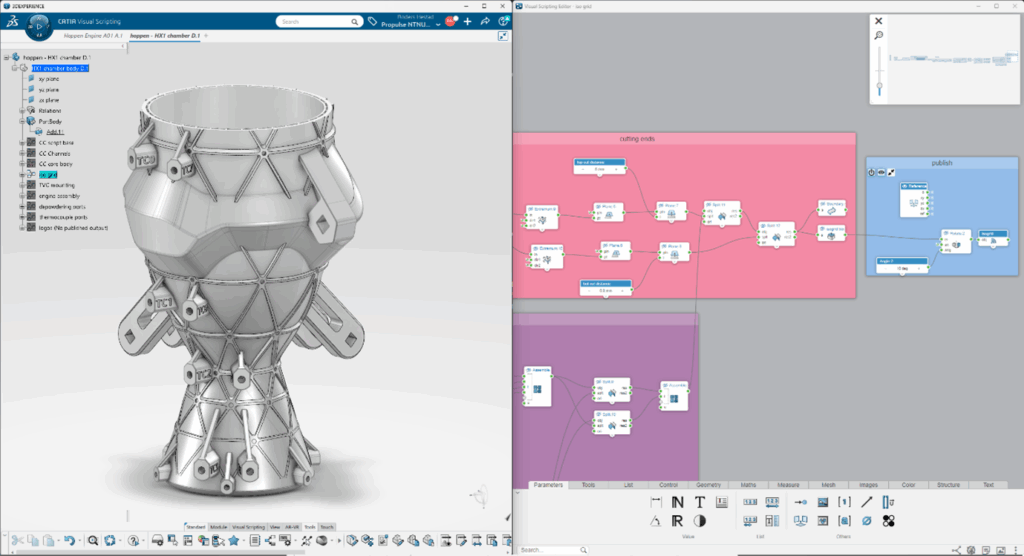

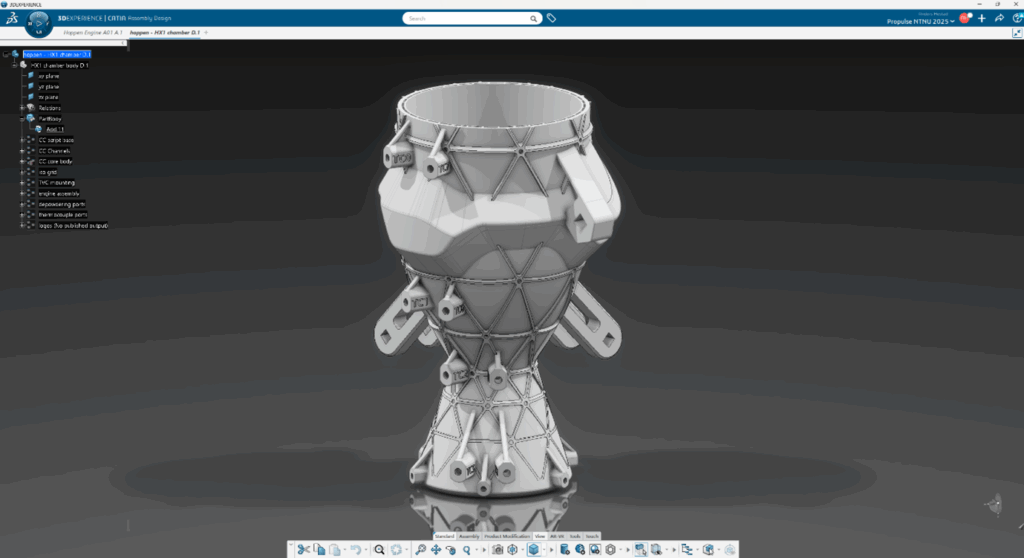

The engine’s lower section was entirely crafted by Anders Hestad, a student of the project, using CATIA Visual Scripting, our algorithmic design software. This showcases the potential of this application in aerospace requirements.

Optimizing Engineering Processes with CATIA Visual Scripting

Using Visual Scripting to design the engine’s cooling channels represents a significant leap in engineering efficiency. This CATIA application allows the team to easily import external data, such as engine parameters, and adjust the design in real-time.

Visual Scripting was also very useful in meticulously designing the cooling channels in an advanced way, to maintain optimal temperatures and prevent overheating. The process involves creating a helical shape with adjustable parameters for channel height and a cross-sectional area, ensuring maximum efficiency.

“The nice thing with Visual Scripting is just being able to drag parameters around, so the geometry updating fast because I do not have to wait for Boolean operations.”

Anders HESTAD, Propulse NTNU project student

By leveraging Visual Scripting, Anders was able to seamlessly integrate complex geometric shapes, make necessary adjustments and optimize these shapes for both performance, to launch the rocket as high as possible, and manufacturability through a 3D printer.

Thermocouple Script: Precision in Temperature Measurement

The intricacies of the thermocouple script are crucial for monitoring temperature variations within the engine. This script enables precise placement of thermocouples, ensuring accurate data collection for performance analysis. It can also be reused for other parts, like the deep powdering ports, to be able to print the engine with the chamber and the injector all in one piece.

The Visual Scripting approach simplifies the process, allowing for dynamic adjustments and easy integration into the overall engine design. This capability is vital for making informed decisions during test phases and ultimately improving engine reliability.

Embracing Visual Scripting: A Cultural Shift

The adoption of Visual Scripting has been transformative for Propulse NTNU. Initially embraced by Anders only, it quickly became an integral part of the team’s design process as a few members tried this innovative and algorithmic approach. The team’s collaborative culture and the support from Dassault Systèmes’ partner, TECHNIA, have enabled members to benefit from knowledge and expertise. Combined with tutorials and a test-and-learn approach, it accelerated Anders’ learning curve on Visual Scripting and helped him master the application in only a few weeks.

“I have kind of fallen in love with the application. (…) It is a little bit of a mindset where if I want to make a part, could I visual script this?”Anders HESTAD, Propulse NTNU project student

This cultural shift has empowered Anders and other team members to explore new possibilities in design and manufacturing for 3D printing, fostering innovation and creativity.

Exploring the CATIA Visual Scripting Application

The Visual Scripting app stands out for its user-friendly interface and seamless integration with the 3DEXPERIENCE CATIA software. It allows users to create complex geometries through a visual programming and algorithmic approach. By describing a sequence of operations, it makes it accessible even for those with limited coding or no coding experience.

Key features of the app include:

- Instant geometry updates, eliminating the need for lengthy regeneration processes.

- Compatibility with standard CAD workflows and other CATIA applications, allowing for easy integration of visually scripted components.

- Robust design capabilities that cater to intricate aerospace requirements.

- And many more features and updates available on the R2025x release by CATIA

“CATIA Visual Scripting is using the CATIA technology, so it is fully compatible with the rest of CATIA applications.”

Edouard SUTRE, CATIA R&D Visual Scripting expert

According to Anders, the app’s versatility and power are evident in the successful design of the engine components of Propulse NTNU’s project.

Conclusion: A Call to Explore Visual Scripting

The journey of Propulse NTNU highlights the transformative potential of CATIA Visual Scripting in engineering and design. By embracing this innovative functionality, Anders and the team have achieved remarkable feats in aerospace technology, setting a new high standard for upcoming projects.

Professionals in the design, engineering, but also architecture and construction industries are encouraged to explore the possibilities of Visual Scripting. Whether optimizing complex designs or enhancing manufacturability, the application offers a versatile solution for modern engineering challenges.

If you are interested in learning more, engage with the CATIA Visual Scripting community and access available resources that can provide valuable insights and guidance on leveraging this powerful application.

And if you want to know more about the Propulse NTNU project and the design of the engine’s cooling channels with Visual Scripting, watch the replay of our CATIA Talk, where Anders and our experts exchange around this fantastic initiative.

FAQ

1) Who is Propulse NTNU and what is their rocket engine project?

Propulse NTNU is a student organization at the Norwegian University of Science and Technology (NTNU) working on a bipropellant liquid rocket engine. Their goal is to deliver 2.5 kN of thrust using ethanol and liquid oxygen, with features like thrust vector control and two-pass regenerative cooling.

2) How is CATIA Visual Scripting used in designing the engine, especially cooling channels?

CATIA Visual Scripting allows parametric control and dynamic updates. The team used it to design helical cooling channels whose geometry (height, cross-sectional area) could be adjusted in real time. They avoided slow Boolean operations and could iterate rapidly.

3) What is the thermocouple script and why is it important?

The thermocouple script automates precise placement of thermocouples for monitoring temperature inside the engine. It’s reusable for other components (e.g. powder ports), aiding accurate data collection and integration into the overall design.

4) What advantages does Visual Scripting bring over traditional CAD workflows in aerospace applications?

Visual Scripting offers instant geometry updates, easier integration of external data inputs, more flexible adjustments, and fast iteration without heavy recomputations. It combines algorithmic flexibility with compatibility with standard CAD workflows.

5) How did adopting Visual Scripting impact the Propulse NTNU team’s workflow and culture?

Originally used by a single team member, Visual Scripting quickly spread across the group. The approach changed mindset: team members began asking, “can I visual-script this part?” Collaboration increased, learning curves shortened (with support from TECHNIA and tutorials), and the process became more exploratory and creative.