At Figure AI, designing a humanoid robot means solving complex questions of motion, reach, weight, and usability. Mechanical engineer Ryan Beneshek explains how CATIA 3DEXPERIENCE helps the team turn ambitious humanoid concepts into real-world machines. From motion simulation to collaborative design in the cloud, digital tools are enabling a new era of robotics engineering.

“How Do You Define a Humanoid?” – Tackling Motion, Reach, and Use Cases

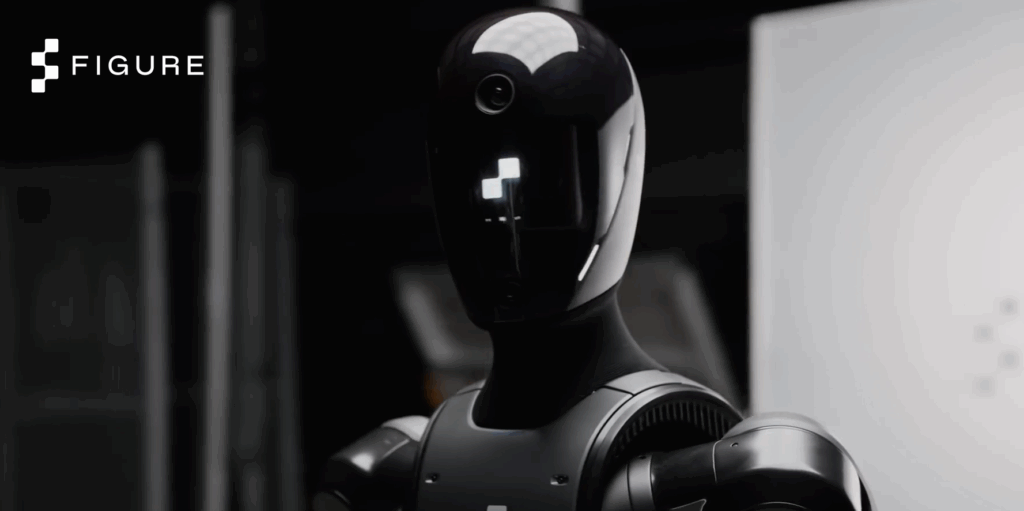

Humanoids are more than machines, they need to move and interact safely in human environments.

It’s how do you define a humanoid, how do you define what it can do, what it’s capable of, what are its use cases to enable that to be successful…It’s very clear that our target is, but it’s how close to that target do we need to hit in order to actually be successful.

At Figure AI, this means designing robots that can reach under tables, access top shelves, and handle objects safely. Every design decision balances weight, battery life, and functionality, making early digital validation critical.

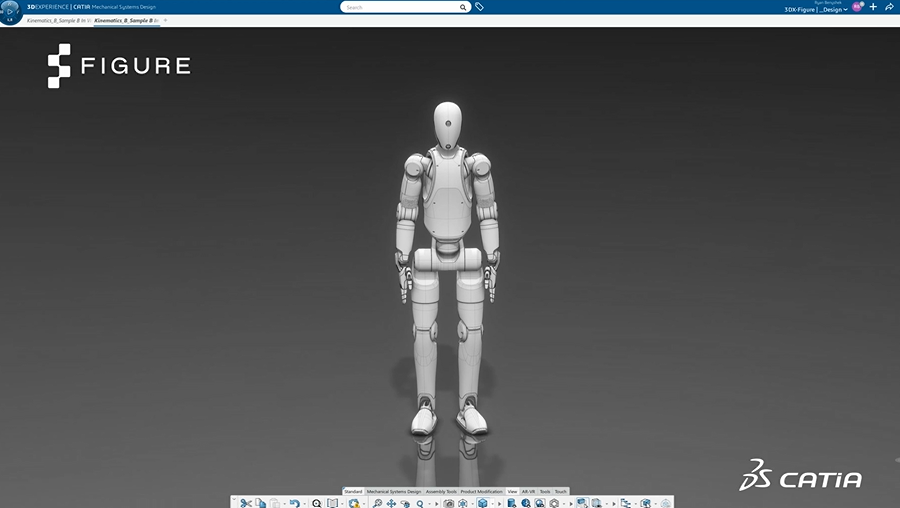

Using CATIA to Check Reach, Motion, and Mechanical Feasibility

CATIA allows engineers to simulate tasks and check whether humanoids can perform them in real-world scenarios.

Early on we’re checking ranges of motion, right? Just like we’re saying, like, can we reach that thing?…let’s actually build it in CATIA, see if we can reach it.

Beyond motion, CATIA enables detailed mechanical design. It integrates industrial design surfacing with advanced structures, wire layouts, and other engineering elements, helping the team combine aesthetics with high-performance engineering.

Weight, Dynamics, and Wiring: Ensuring Robots Work in the Real World

CATIA also addresses real-world constraints.

This also allows us to do some weight trace, just weight roll-ups to actually get better dynamics for our control engineers to build on

The platform supports rapid validation of wiring harnesses, PCB layouts, and packaging, ensuring every component fits and functions as intended. When design limits are reached, the team can explore trade-offs between architecture and industrial design to achieve optimal performance.

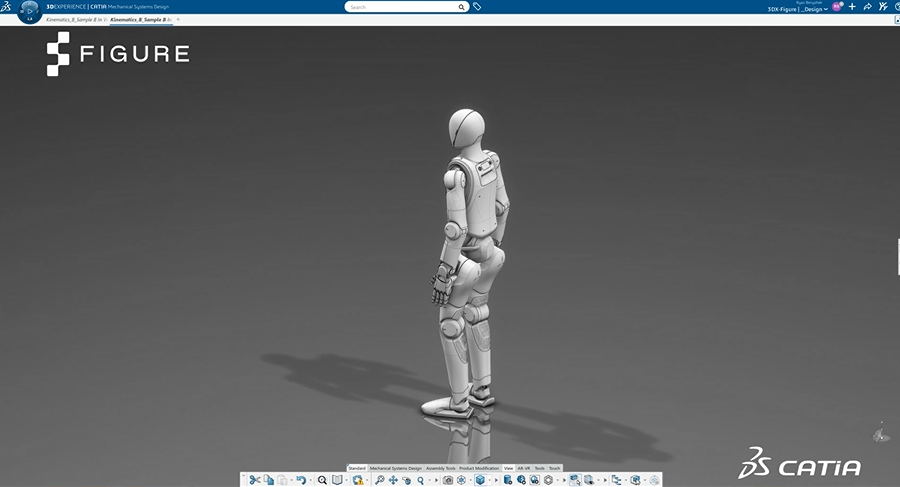

Collaborative Cloud Design: Real-Time Updates Across Teams

The 3DEXPERIENCE cloud environment transforms teamwork at Figure AI.

We’re working on cloud, so it’s very collaborative being able to modify one of the designs, update it, have someone else automatically see that on their end…Working in 3D allows us to do quick validations and check.

This real-time collaboration accelerates the design cycle and allows mechanical engineers, industrial designers, and control engineers to iterate together. Everyone stays aligned, improving both speed and accuracy in humanoid development.

Conclusion

Figure AI’s work demonstrates how CATIA 3DEXPERIENCE empowers engineers to tackle the most complex humanoid robotics challenges. By uniting industrial design, mechanical engineering, and real-world validation in one collaborative platform, teams can innovate faster and smarter.

FAQ

Q1: What is CATIA and how is it used in humanoid robotics?

CATIA is a 3D design and engineering platform used to create complex mechanical systems and industrial designs. In humanoid robotics, CATIA allows engineers to model motion ranges, optimize weight, and integrate electronics to ensure robots perform tasks safely and efficiently.

Q2: How does CATIA help reduce the design cycle for robotics projects?

CATIA with 3DEXPERIENCE platform supports collaborative, cloud-based design, enabling real-time updates across teams. Engineers can quickly validate designs, adjust mechanical layouts, and integrate industrial design feedback, significantly shortening the time from concept to prototype.

Q3: Can CATIA simulate real-world constraints like motion, weight, and battery life?

Yes. Engineers use CATIA to simulate robot motion, perform weight roll-ups, and analyze dynamic performance. This allows control engineers to optimize systems while ensuring the humanoid can complete tasks safely and efficiently.

Q4: How does CATIA support collaboration among design, mechanical, and electronics teams?

CATIA’s cloud-based environment allows multiple teams to work on the same model simultaneously. Changes in design, wire harness layouts, or PCB placements are instantly visible to all stakeholders, improving coordination and reducing errors.

Q5: Why is CATIA important for integrating industrial design with mechanical engineering?

Humanoid robots require both aesthetic appeal and functional precision. CATIA enables the seamless combination of high-class industrial design surfaces with advanced mechanical and structural systems, ensuring robots are both visually appealing and technically performant.