Every robotics startup starts with just a clever idea. A clever idea that will bring technology to a specific industry, use case or application and answer the growing need for automation, due in particular to worldwide human aging and the labor shortage it creates, but also for re- and nearshoring demand based on global supply-chain issues.

Figures reflect this observation. The number of industrial robots has consistently increased in the past few years and will keep doing so: we can expect a growth of 7% per year from 2023 until 2030. There is a similar trend for services robots with a growth of 37% of professional service robots in 2021.*

Traditional Robotics players will not be able to cover the increasing gap of robotic-based automation worldwide alone the next 10 years. Therefor the attention from the markets is extremely high to the new powerful Robotics Startups communities to close the gap. Last year more than $17 billion poured into VC-backed robotic startups, nearly triple the investment in 2020. This year is a little behind that pace, but the sector already has seen more than $5 billion flow to startups *.

Traditional industries, new segments and uses cases: all sectors are concerned worldwide, providing thereby a fertile ground for startups to innovate. So more and more are appearing to try to find their niche to tackle competition.

However, having a clever idea is not enough because as the project gets more concrete, the company created and the investor found, robotic startups find themselves facing specific challenges. The first one being the need to develop, test, and produce their first robot quickly as well as to validate their innovation. At the same time they have to reassure investors looking for fast results and ensure their sustainability.

But how can they achieve this?

How to get your innovative robot to market… fast?

From design to production and beyond… The road can be a bumpy one, especially for startups who do not already have established processes and the organizational maturity at the beginning.

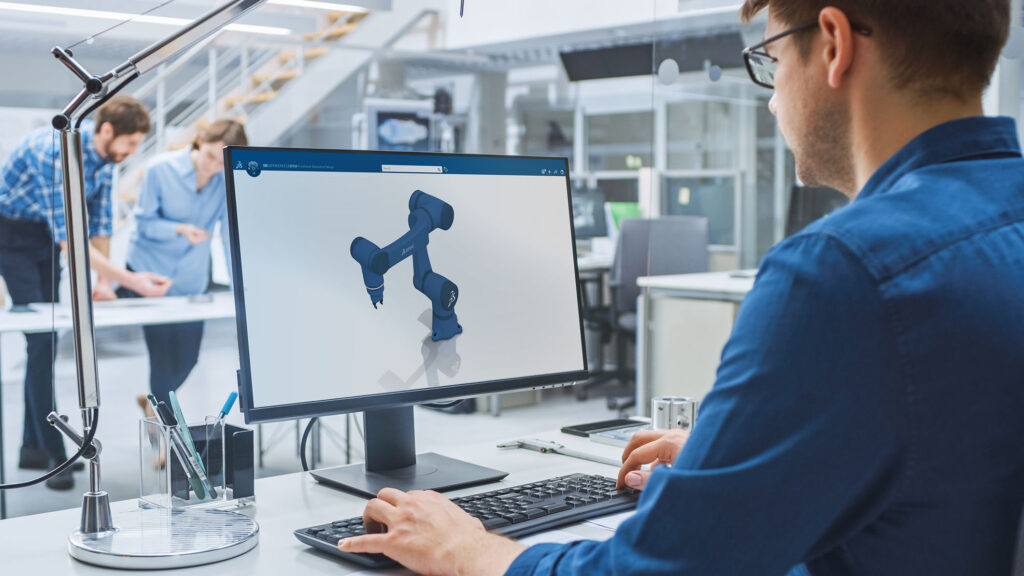

Robot design: born from intense collaboration

Collaboration is crucial from the initial stages of robot design and development. Designing robots requires the seamless integration of different disciplines such as mechanical, electrical, and software, as well as collaboration between different companies and suppliers. This necessitates access to a solution that enables stakeholders to access all product development data anywhere, anytime, perform their tasks, and monitor the project to ensure it meets their requirements and regulations. Robotics startups that can establish such a collaborative environment can validate their design and swiftly bring their innovative robots to market.

However, speed is not the only determining factor for startups when it comes to product development. Cost is another one. Traditionally, the robotic industry relied heavily on physical prototyping to validate new robots or new applications, each step of the product development. If the process can still be used by bigger players, it is simply too costly for startups. In that regard, leveraging simulation in a virtual environment to reduce physical prototyping is critical.

Next step: production

Once the design of the robot is validated, next step is production, the industrialization step of the new product. If startups cannot have their own production site, they have to first use an external production partner.

To make things easier, startups entrust production to a local supplier to implement the new manufacturing processes After that, they can go to a global supplier when starting mass-production and focusing on sales in high-potential regional markets as a good way to reduce costs. Either way, cross-company collaboration needs to be on a single platform to be seamless and efficient, especially when it comes to a global approach.

Startups can benefit greatly from using a cloud solution in their production process. It enables remote collaboration with suppliers, reduces costs, misunderstandings and errors, and speeds up the production process without needing a significant portion of the startup’s limited workforce to set up a physical production site.

Whether the production is internal or external, streamlined processes need to connect engineering to manufacturing efficiently and the other way around. Digital continuity will enable optimal production and continuous improvement.

Gather valuable data across the entire process

Startups that lack prior experience must prioritize continuous improvement. Gathering real data from the systems in operation, once the robot is in use, is crucial in identifying issues and gaining valuable insight. This data can inform the design, engineering, and manufacturing process and aid in continuous improvement. It will also help quality engineers to generate predictive maintenance operations allowing robotics startups to go one step further in their relation with clients and draw nearer to a service-based model.

In order to do so, information silos need to be broken and data coming from various sources need to be collected, collated, contextualized and analyzed in one single platform.

Innovative robots are coming soon. Does the world know?

These days, companies no longer need to wait for their first prototype before they can start marketing their product. This Nowadays, companies don’t have to wait for a prototype before promoting their product, which is beneficial for startups. They can begin marketing their innovation while still in the design phase, allowing them to bring their product to market faster.

Startups often lack the resources to create assets, so they require tools that can easily generate product showcases. Ideally, these tools would utilize current CAD data to create visuals and 3D models of their robots.

Why is it important? Robotics startups:

- no longer need specific competencies to start convincing clients,

- can secure sales earlier in the process,

- can show concretely the benefits of using their robot.

The ability to represent the robot using a 3D model is essential when presenting an innovative solution, robot or application for a full comprehension of its usage and positive impact on today’s way of working.

The 3DEXPERIENCE platform can support you.

To tackle product, market and organizational complexities, robotic startups can adopt the 3DEXPERIENCE platform on the cloud and benefit from it. Dassault Systèmes’ 3DEXPERIENCE platform provides companies with a unique and integrated solution to virtualize their processes. A cloud-based platform where they can connect the dots from robot design to marketing activities, from production to maintenance and bring their product to market up to 30% faster.

For startups, cloud means the ability, without any IT investments, to boost their business with an end-to-end solution and support right from the start and can grow with the company as it evolves.

Concrete benefits come fast when you are a startup because as you start, everything that helps manage the organizational aspects and ease collaboration between stakeholders is highly welcomed. Organizing communities, ecosystems, data around the innovative project in one single source-of-truth will help startups get everyone on the same page as well as work seamlessly and effectively.

Are you a startup interested in these solutions? Learn more by following this link.

If you’d like to learn more about the robot provider’s digital journey, listen to our podcasts below

* World Robotics 2022, IFR – International Federation of Robotics